Desulfurization waste water zero-discharging treatment technology for coal-fired power plants

A technology for desulfurization wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

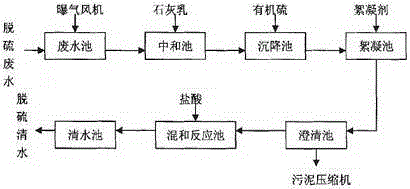

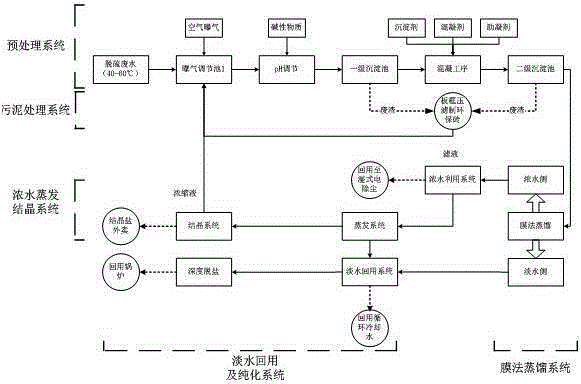

Method used

Image

Examples

Embodiment 1

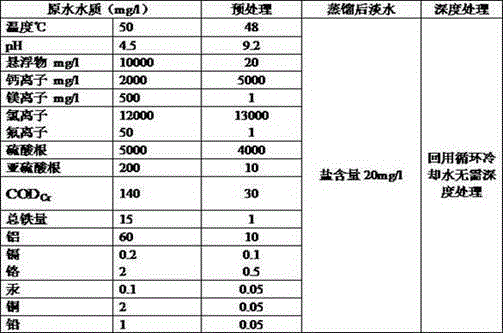

[0053] The desulfurization system of a 600MW ultra-supercritical unit in a power plant shares a comprehensive wastewater treatment system with automatic control function. The wastewater treatment volume is about 12t / h, and the circulating cooling water is planned to be reused. Excess indicators in wastewater are mainly suspended solids, pH value, mercury, copper, lead, arsenic, fluorine, calcium, magnesium, aluminum, iron, and chloride, sulfate, sulfite, carbonate, etc. Dosing regimen is as follows:

[0054]

[0055] The effluent quality of each relevant treatment process is as follows:

[0056]

Embodiment 2

[0058] The desulfurization system of a 300MW ultra-supercritical unit in a power plant shares a comprehensive wastewater treatment system with automatic control function. The wastewater treatment volume is about 6t / h, and the circulating cooling water is planned to be reused. Excess indicators in wastewater are mainly suspended solids, pH value, mercury, copper, lead, arsenic, fluorine, calcium, magnesium, aluminum, iron, and chloride, sulfate, sulfite, carbonate, etc. Dosing regimen is as follows:

[0059]

[0060] The effluent quality of each relevant treatment process is as follows:

[0061]

Embodiment 3

[0063] The desulfurization systems of two 2×600MW ultra-supercritical units in a power plant share a comprehensive wastewater treatment system with automatic control function. The wastewater treatment volume is about 24t / h, and the circulating cooling water is planned to be reused. Excess indicators in wastewater are mainly suspended solids, pH value, mercury, copper, lead, arsenic, fluorine, calcium, magnesium, aluminum, iron, and chloride, sulfate, sulfite, carbonate, etc. Dosing regimen is as follows:

[0064]

[0065] The effluent quality of each relevant treatment process is as follows:

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com