Preparation method for molybdenum disulfide quantum dot

A technology of molybdenum disulfide and quantum dots, applied in the direction of molybdenum sulfide, etc., can solve the problems of large environmental pollution, time-consuming, complicated preparation process, etc., and achieve the effect of simple equipment, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing molybdenum disulfide quantum dots, comprising the following steps: (1) dispersing molybdenum disulfide powder in absolute ethanol, the concentration of the solution prepared by dispersing the molybdenum disulfide powder in absolute ethanol is 0.5 -10mg / mL (0.5mg / mL, 1.0mg / mL, 2.0mg / mL, 3.0mg / mL, 4.0mg / mL, 5.0mg / mL, 6.0mg / mL, 7.0mg / mL, 8.0mg / mL can be selected mL, 9.0mg / mL, 10mg / mL); add sodium hydroxide to the solution, the amount of sodium hydroxide added is 0.5-3mg / mL (0.5mg / mL, 1.0mg / mL, 1.5mg / mL, 2.0mg / mL, 2.5mg / mL, 3.0mg / mL), ultrasonically mixed to obtain a mixed solution;

[0026] (2) Transfer the mixed solution described in step (1) to the reactor, seal it, and react in an oven at 100-200°C (100°C, 120°C, 140°C, 160°C, 180°C, 200°C) for 3 -24h (3h, 6h, 9h, 12h, 15h, 18h, 21h, 24h can be selected), naturally cool to room temperature, and collect the filtrate after filtration;

[0027] (3) Dialyze the filtrate obtained in step (2) to neutr...

Embodiment 1

[0030] Disperse 30mg of molybdenum disulfide powder in 30mL of absolute ethanol, add 45mg of sodium hydroxide, mix ultrasonically for 1min, transfer the mixed solution to a reaction kettle, raise the temperature to 180°C for 12h, and naturally cool to room temperature. The product is filtered and separated by a 0.22 μm microporous membrane to obtain a yellow solution, and the obtained solution is transferred to a dialysis bag with a molecular weight cut-off of 1000D and dialyzed to neutrality to remove small impurities, and then freeze-dried at -40°C to obtain molybdenum disulfide quantum dots.

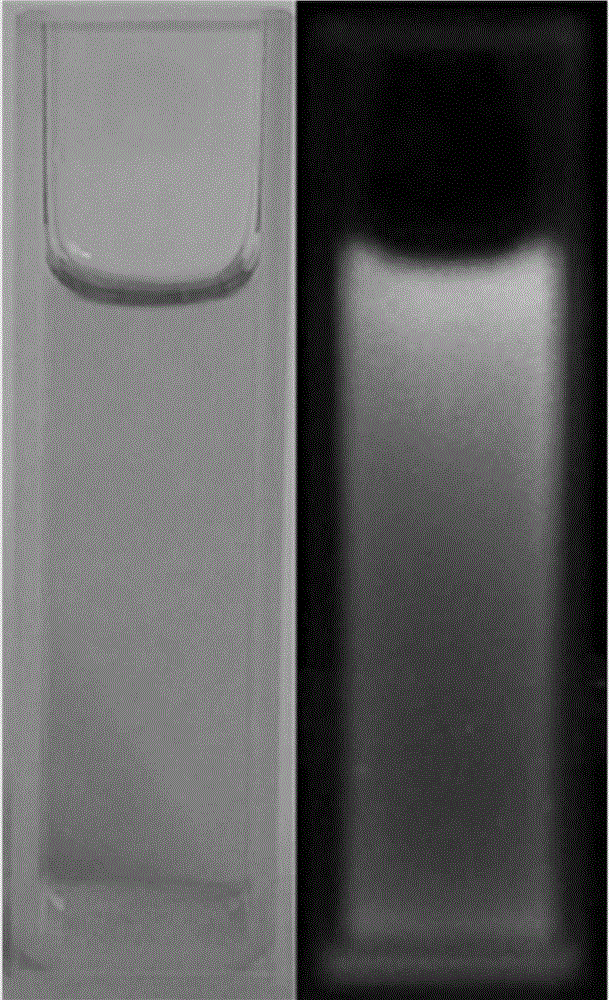

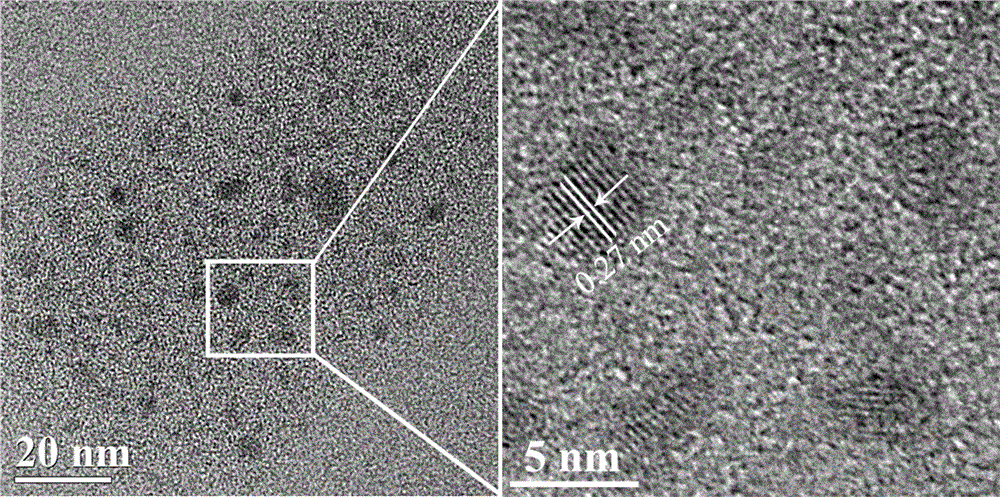

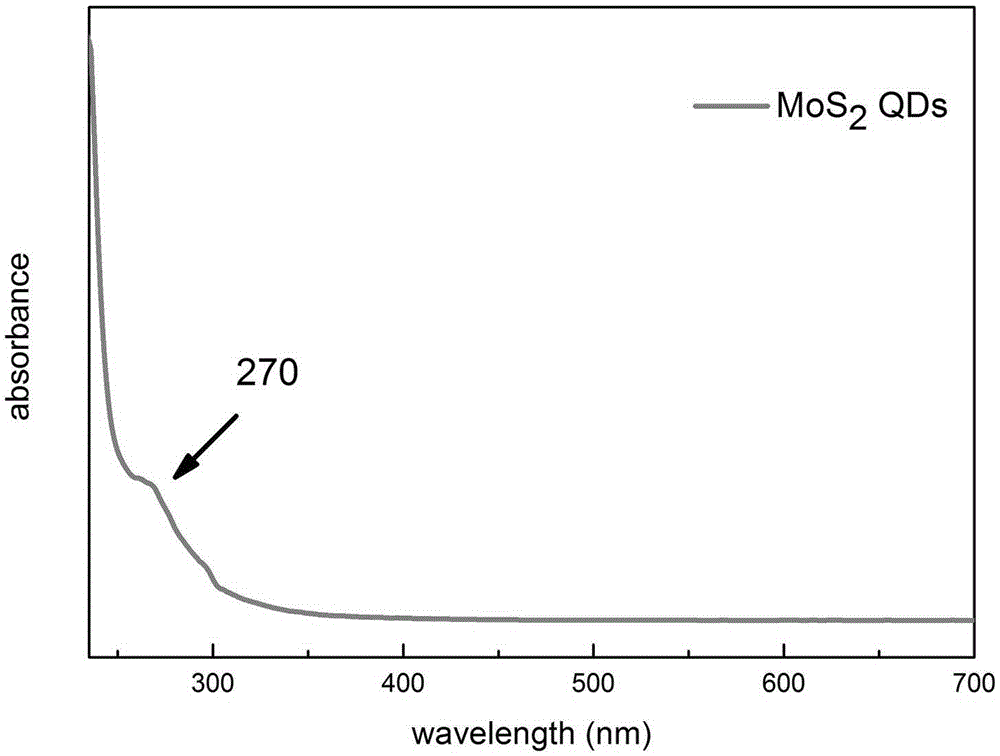

[0031] figure 1 and substantive examination reference figure 1 The pictures of the molybdenum disulfide quantum dot aqueous solution prepared in Example 1 under sunlight and ultraviolet light irradiation. referenced by substantive examination figure 1 It can be seen that the molybdenum disulfide quantum dots obtained in this example exhibit strong blue fluorescence under the irradi...

Embodiment 2

[0033] Disperse 60mg of molybdenum disulfide powder in 30mL of absolute ethanol, add 30mg of sodium hydroxide, mix ultrasonically for 1min, transfer the mixed solution to a reaction kettle, raise the temperature to 200°C for 6h, and naturally cool to room temperature. The product is filtered and separated by a 0.22 μm microporous membrane to obtain a yellow solution, and the obtained solution is transferred to a dialysis bag with a molecular weight cut-off of 1000D and dialyzed to neutrality to remove small impurities, and then freeze-dried at -40°C to obtain molybdenum disulfide quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com