Method for large-scale preparation of transition metal oxide porous microsphere

A technology of porous microspheres and transition metals, applied in iron oxide, microsphere preparation, nickel oxide/nickel hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

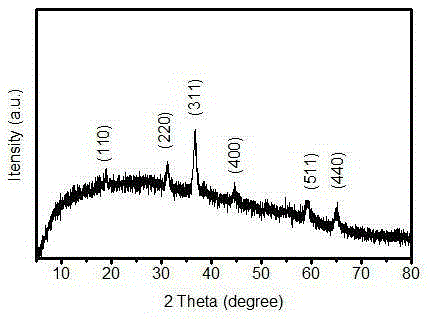

[0022] co 3 o 4 Preparation of porous microspheres

[0023] 1) Use a 50mL graduated cylinder to measure 30mL of ethylene glycol and dissolve it in a 200mL beaker with 120mL of isopropanol, stir for 2 hours to form a homogeneous solution with a mass concentration of ethylene glycol of 26.8%;

[0024] 2) Under stirring conditions, 3.35g of cobalt nitrate hexahydrate was added to the homogeneous solution, and a homogeneous precursor solution was obtained after stirring for 1 hour;

[0025] 3) Transfer the obtained precursor solution to Yacheng YC-018 spray dryer for drying. The air inlet temperature is 350°C, the air outlet is 90°C, the drying gas is nitrogen, and the feed rate is 4mL / min. The obtained powder Collected from the bottom of the drying tower and cyclone separator;

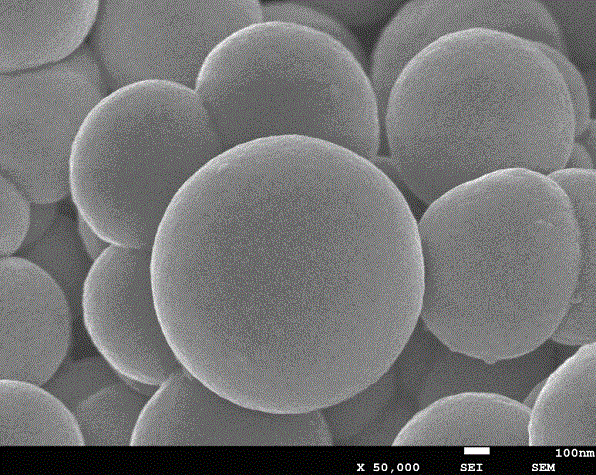

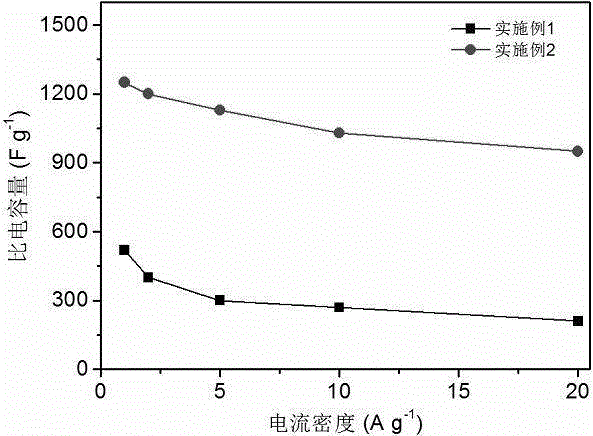

[0026] 4) The obtained powder was placed in a muffle furnace at a heating rate of 2 °C / min to 350 °C for 3 h, and then naturally cooled to room temperature to obtain Co with an average diameter of 4.79...

Embodiment 2

[0029] NiCo 2 o 4 Preparation of porous microspheres

[0030] 1) Use a 10mL graduated cylinder to measure 10mL of ethylene glycol and dissolve it in a 100mL beaker filled with 80mL of ethanol, and stir for 1 hour to form a homogeneous solution with a mass concentration of ethylene glycol of 11.1%;

[0031] 2) Under stirring conditions, dissolve 3.57g of cobalt nitrate hexahydrate and 1.79g of nickel nitrate hexahydrate into the homogeneous solution, and keep stirring for 2 hours to obtain a homogeneous precursor solution;

[0032] 3) Transfer the obtained precursor solution to Yacheng YC-018 spray dryer for drying. The air inlet temperature is 300°C, the air outlet is 100°C, the drying gas is nitrogen, and the feed rate is 2mL / min. The obtained powder Collected from the bottom of the drying tower and cyclone separator;

[0033] 4) Put the obtained powder in a muffle furnace to heat up to 400°C for 2 hours at a rate of 1°C / min for calcination, and then naturally cool to room t...

Embodiment 3

[0037] Fe 2 o 3 Preparation of porous microspheres

[0038] 1) Use a 10mL graduated cylinder to measure 5mL glycerol and dissolve it in a 100mL beaker filled with 80mL isopropanol, and stir for 1 hour to form a homogeneous solution with a mass concentration of glycerol of 7.4%;

[0039] 2) Under stirring conditions, add 3.64g of ferric nitrate nonahydrate into the homogeneous solution, and keep stirring for 2 hours to obtain a homogeneous precursor solution;

[0040] 3) Transfer the obtained precursor solution to Yacheng YC-018 spray dryer for drying. The air inlet temperature is 220°C, the air outlet is 90°C, the drying gas is nitrogen, and the feed rate is 2.5mL / min. The obtained powder The body is collected by the bottom of the drying tower and the cyclone separator;

[0041] 4) Put the obtained powder in a muffle furnace to heat up to 650°C for 2 hours at a rate of 3°C / min, and then cool naturally to room temperature to obtain Fe with an average diameter of 380nm. 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com