Preparation method for glass and glass film both containing rare-earth-ion-doped lutetium chloride microcrystalline

A glass film, rare earth ion technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as device development limitations, achieve the effect of overcoming incomplete uniformity, preventing decomposition and volatilization, and promoting densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

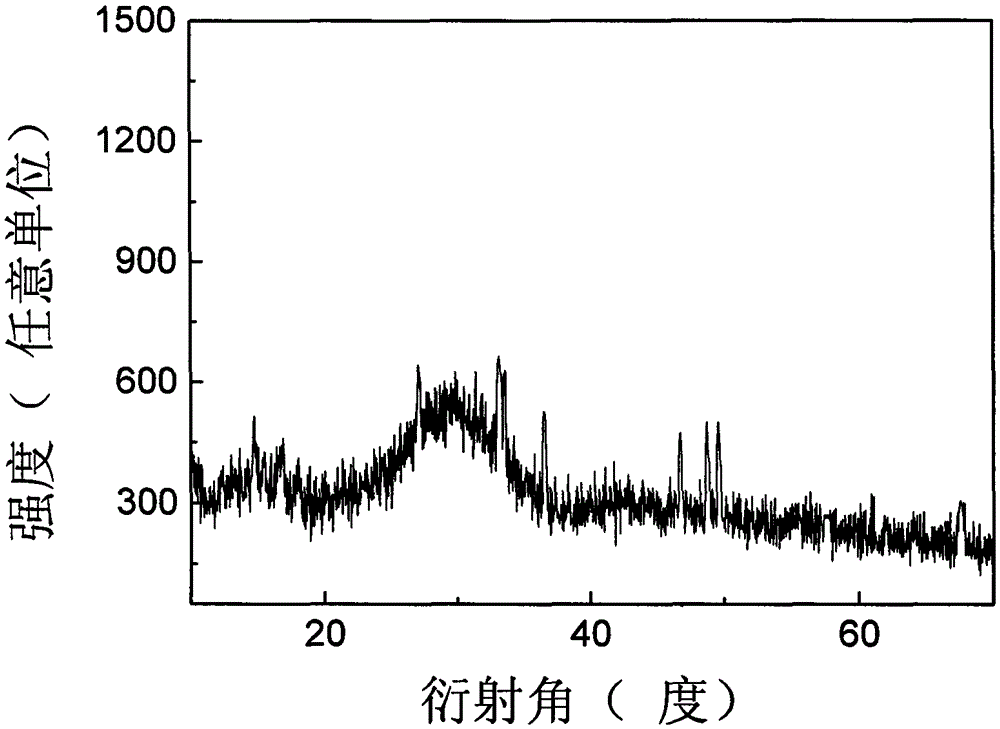

[0040] The preparation method of glass and glass thin film containing rare earth ion-doped lutetium chloride crystallite comprises the following steps:

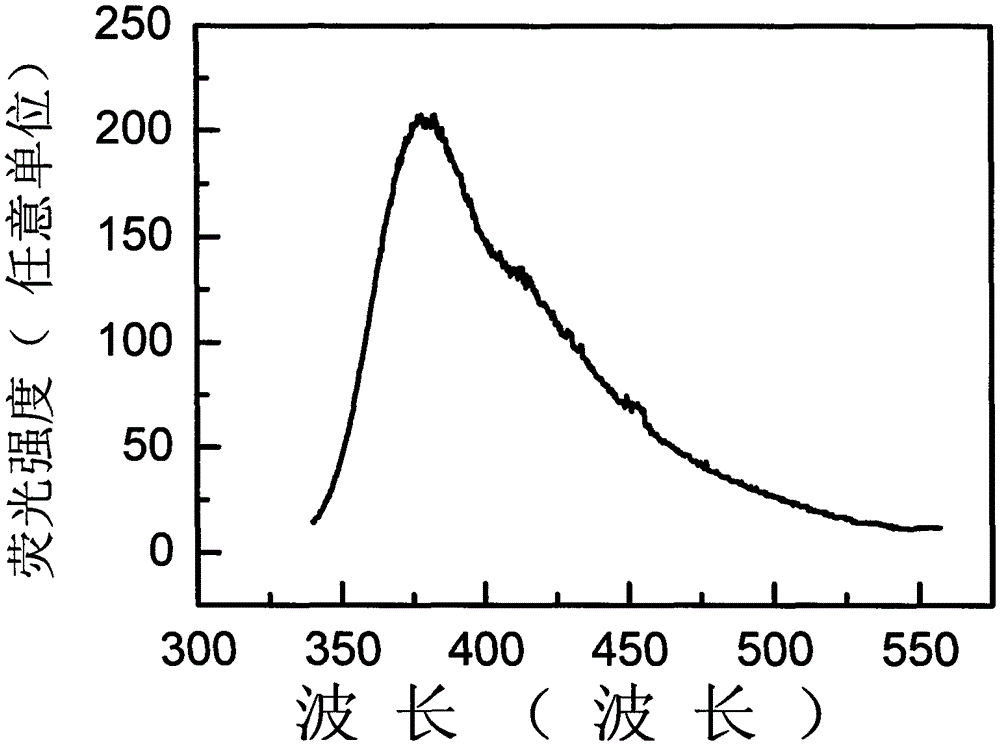

[0041] (1), the preparation raw materials are composed by mole percent: ethyl orthosilicate: 65mol%, aluminum sec-butoxide: 24mol%, lutetium chloride: 10mol%, cerium chloride: 1mol%, and the total amount is weighed to be 20 Each preparation raw material of the analytical purity of gram, stand-by;

[0042] (2), according to the following molar ratio: the sum of tetraethyl orthosilicate and aluminum sec-butoxide: dehydrated alcohol: distilled water=1: 2.5: 2, weigh corresponding dehydrated alcohol and distilled water respectively, and set aside;

[0043] (3), hydrolysis of aluminum sec-butoxide: take 1 / 3rd of the dehydrated alcohol weighed in the step (2), dissolve all the aluminum sec-butoxide weighed in the step (1), add ice rapidly Acetic acid, the volume ratio of aluminum sec-butoxide and glacial acetic acid is 1: 1, and c...

Embodiment 2

[0054] Basically the same as Example 1, the difference is that in step (1), the raw materials are prepared in the following molar percentages: tetraethyl orthosilicate: 70mol%, aluminum sec-butoxide: 10mol%, lutetium chloride: 15mol%, chlorine Europium chloride: 5mol%, each preparation raw material that takes by weighing total amount is 20 grams, stand-by; In step (8), solution E is coated on the clean quartz glass substrate by dip-coating, The pulling speed of the quartz glass substrate in the gel solution is controlled at 1 mm / s, and it is pulled 5 times, and the interval between each pulling is 15 minutes to obtain a glass film; in step (10), put it in the furnace The glass film or glass is kept at 100°C for 2 hours to remove residual water and ethanol, and then heated to 360°C and held for 40 minutes to remove residual organic matter. The heating rate for glass is 15°C per hour. The cooling rate is 20°C per hour, the heating rate of the glass film is 50°C per hour, and the...

Embodiment 3

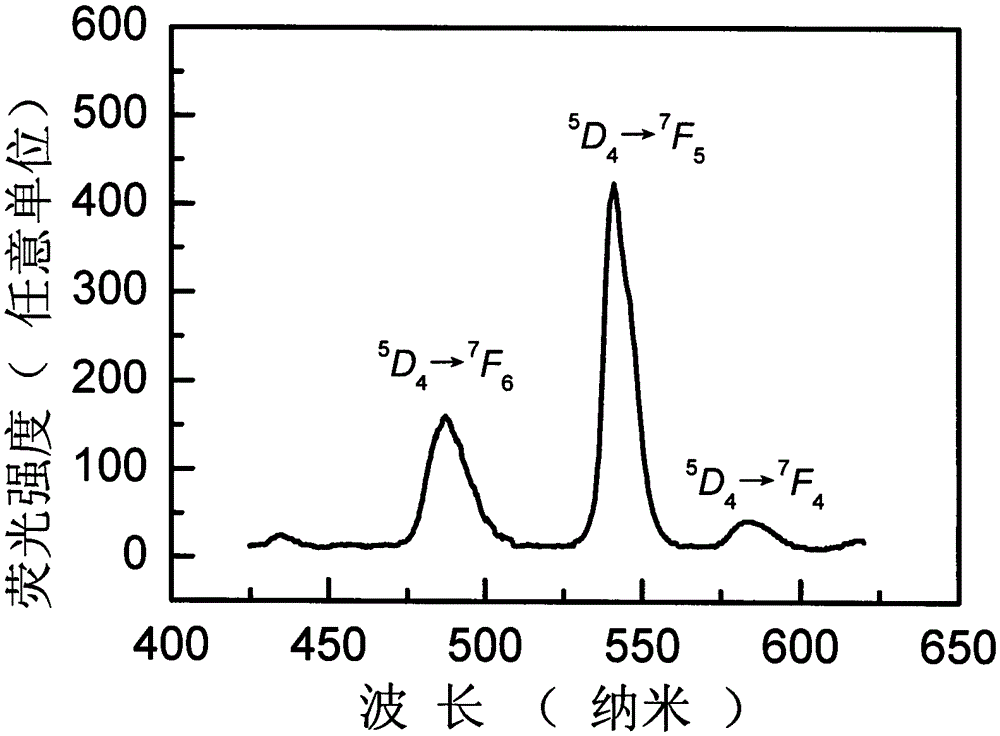

[0057] Basically the same as Example 1, the difference is that in step (1), the raw materials are prepared in the following molar percentages: tetraethyl orthosilicate: 67mol%, aluminum sec-butoxide: 18mol%, lutetium chloride: 13mol%, chlorine Terbium: 2mol%, take by weighing a total amount of 20 grams of analytically pure ethyl orthosilicate, aluminum sec-butoxide, lutetium chloride and terbium chloride raw materials, stand-by; in step (8), the pulling speed Controlled at 0.6 mm / s, according to the specific thickness requirements, the pulling can be repeated 3 times, and the interval between each pulling is 15 minutes, and the coated film is dried at room temperature for 4 hours to obtain a glass film; in step (10) In the process, put the glass film or glass in the furnace at 100°C for 1.5 hours to remove residual water and ethanol, then raise the temperature to 360°C and hold for 30 minutes to remove residual organic matter, the heating rate for glass 12°C per hour, the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com