Boron-doped single-particle-layer nano-diamond film and preparation method thereof

A nano-diamond, single-particle technology, applied in chemical instruments and methods, coatings, metal material coating processes, etc., to achieve good electrochemical catalytic performance, high catalytic efficiency, and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

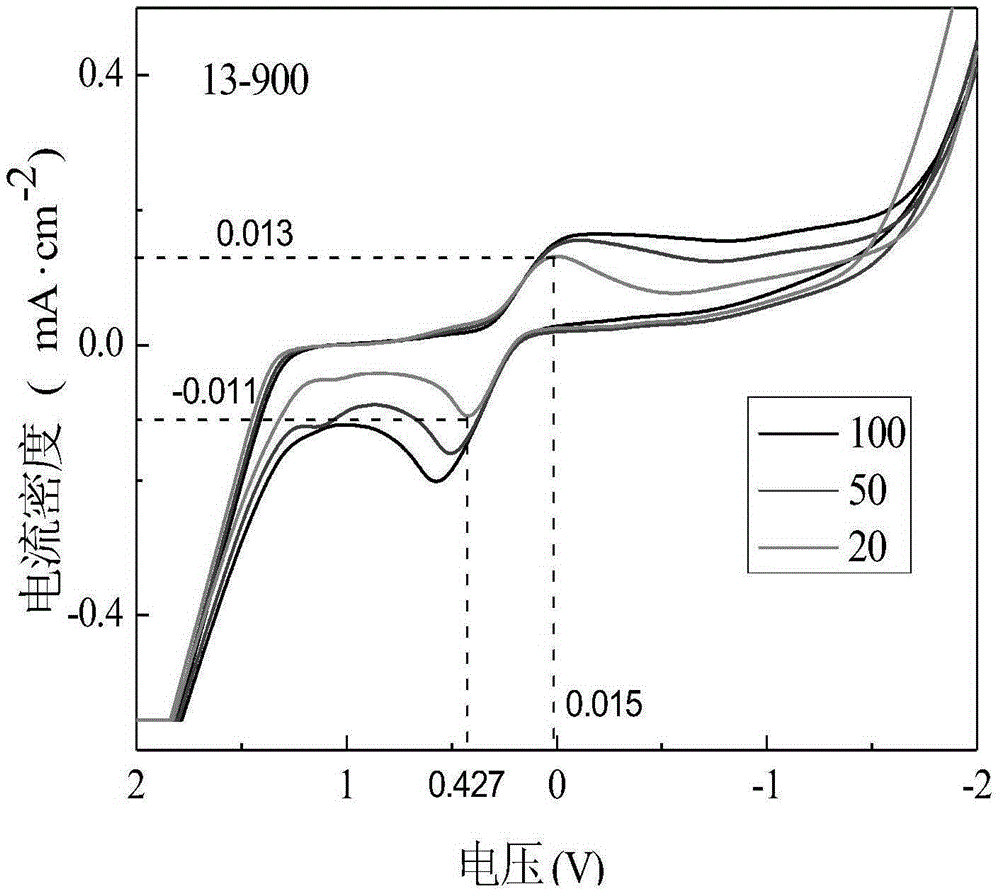

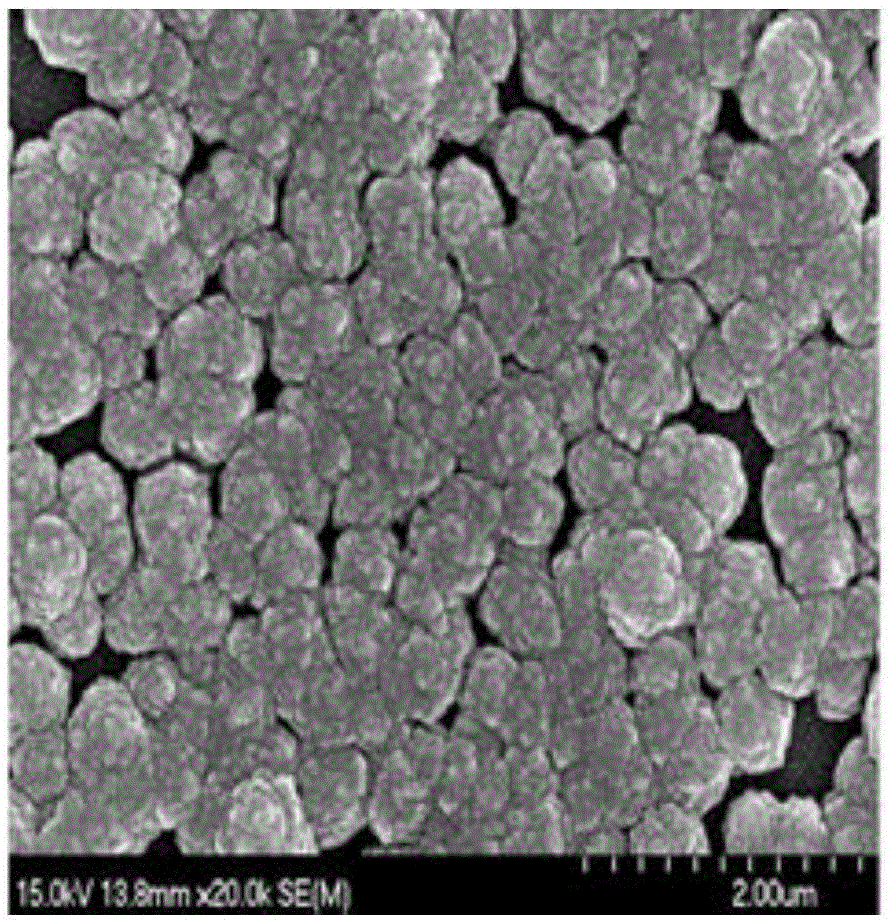

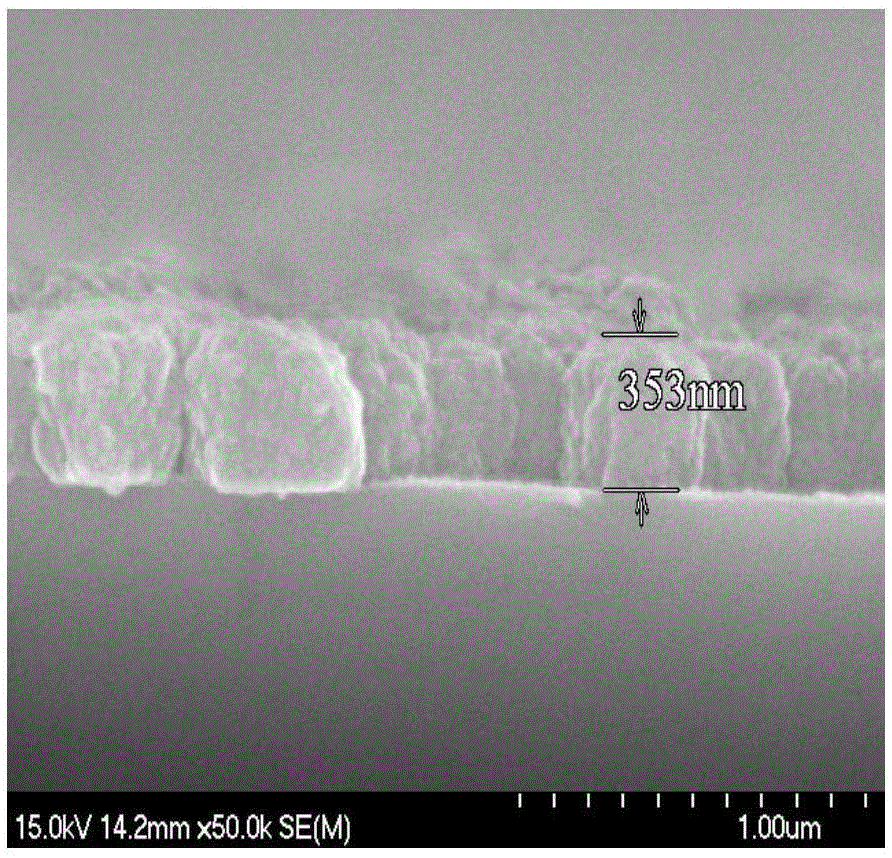

Embodiment 1

[0039] The monocrystalline silicon wafer is polished with nanometer diamond powder, and the polishing time is about half an hour. Polished silicon wafers were ultrasonically cleaned with deionized water and acetone in turn, dried, and used as substrates for the growth of nano-diamond films. Using hot wire chemical vapor deposition (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., model JUHFCVD001), using acetone as the carbon source, acetone was brought into the reaction chamber by hydrogen bubbling, hydrogen, acetone The flow ratio is 200:90, the reaction power is 2000W, the distance between the hot wire and the substrate silicon wafer is 7mm, and the working pressure is 1.63Kpa; no bias is applied during the reaction process, and the preparation time is 15 minutes; The temperature of the sample is cooled under the condition of not flowing hydrogen, and a single particle layer nano-diamond film with a thickness of 300-400nm is pre...

Embodiment 2

[0045] The monocrystalline silicon wafer is polished with nanometer diamond powder, and the polishing time is about half an hour. The polished silicon wafers were washed with deionized water and acetone in an ultrasonic machine, dried, and used as substrates for the growth of nano-diamond films. Using hot wire chemical vapor deposition (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., model JUHFCVD001), using acetone as the carbon source, acetone was brought into the reaction chamber by hydrogen bubbling, hydrogen, acetone The flow ratio is 200:90, the reaction power is 2000W, the distance between the hot wire and the substrate silicon wafer is 7mm, the working pressure is 1.63Kpa; no bias is applied during the reaction process, and the film preparation time is 15 minutes. After the growth is completed, the temperature of the sample is cooled under the condition of not flowing hydrogen, and a single particle layer nano-diamond film...

Embodiment 3

[0049] The monocrystalline silicon wafer is polished with nanometer diamond powder, and the polishing time is about half an hour. The polished silicon wafers were washed with deionized water and acetone in an ultrasonic machine, dried, and used as substrates for the growth of nano-diamond films. Using hot wire chemical vapor deposition (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., model JUHFCVD001), using acetone as the carbon source, acetone was brought into the reaction chamber by hydrogen bubbling, hydrogen, acetone The flow ratio is 200:90, the reaction power is 2000W, the distance between the hot wire and the substrate silicon wafer is 7mm, the working pressure is 1.63Kpa; no bias is applied during the reaction process, and the film preparation time is 15 minutes. After the growth is completed, the temperature of the sample is cooled under the condition of not flowing hydrogen, and a single particle layer nano-diamond film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com