Preparation technology of modified positive material lithium nickel manganese oxide for lithium-ion battery

A lithium-ion battery and cathode material technology, applied in the field of preparation of modified lithium nickel manganese oxide, can solve the problem of poor cycle performance, thermal stability and high temperature performance, poor battery safety and thermal stability, and difficult to realize Lithium cobalt oxide replacement and other issues, to achieve good marketing value, improve conductivity and cycle performance, moderate particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

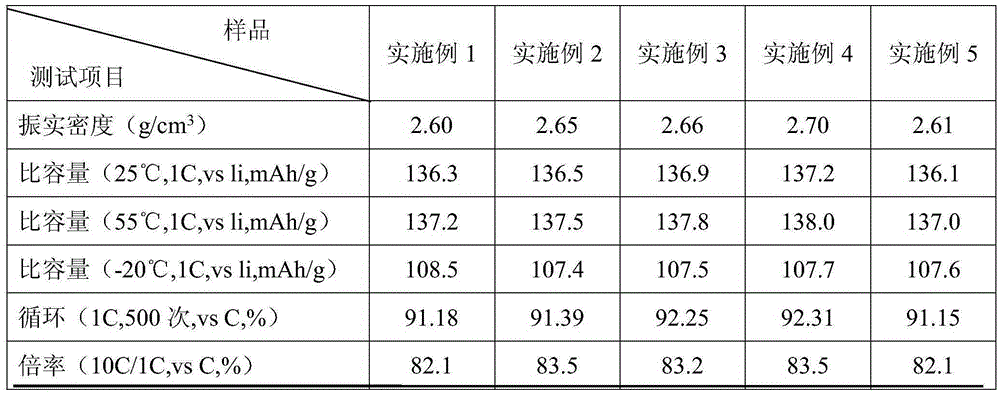

Examples

Embodiment 1

[0035] (1) Preparation of manganese salt and nickel salt materials: mix manganese sulfate and nickel sulfate materials with a Mn:Ni molar ratio of 3:1;

[0036] (2) The sol-gel method prepares the nickel-manganese precursor: the mixture obtained in step (1) is added in the chelating agent polyethylene glycol-1000, and the quality of the chelating agent is 120% of the metal Mn+Ni quality, with ammonium bicarbonate Adjust the pH to 8-10, stir until viscous, add pure water under stirring to make a solution with a metal Mn+Ni ion concentration of 100g / l, add a sedimentation aid hydroxyl that is 3% of the metal Mn+Ni Methyl cellulose until the precipitation is complete, filter, and dry the precipitate to obtain a nickel-manganese precursor;

[0037] (3) Three-dimensional oblique mixing: use a three-dimensional oblique mixer to mix the nickel-manganese precursor obtained in step (2) with lithium carbonate and cationic Mg 2+ and anion F - The compound was dispersed and mixed for 2....

Embodiment 2

[0044] (1) Preparation of manganese salt and nickel salt materials: mix manganese nitrate and nickel nitrate materials with a Mn:Ni molar ratio of 3:1;

[0045] (2) The sol-gel method prepares the nickel-manganese precursor: the mixture obtained in step (1) is added in the chelating agent polyethylene glycol-4000, and the quality of the chelating agent is 100% of the metal Mn+Ni quality, with ammonium bicarbonate Adjust the pH to 8-10, stir until viscous, add pure water under stirring to make a solution with a metal Mn+Ni ion concentration of 120g / l, add a sedimentation aid hydroxyl that is 5% of the metal Mn+Ni Methyl cellulose until the precipitation is complete, filter, and dry the precipitate to obtain a nickel-manganese precursor;

[0046] (3) Three-dimensional oblique mixing: use a three-dimensional oblique mixer to mix the nickel-manganese precursor obtained in step (2) with lithium carbonate and cationic Ti 4+ and anion F - The compound was dispersed and mixed for 3....

Embodiment 3

[0053] (1) Preparation of manganese salt and nickel salt materials: mix manganese chloride and nickel chloride materials with a Mn:Ni molar ratio of 3:1;

[0054] (2) Sol-gel method to prepare nickel-manganese precursor: the mixture of step (1) gained is added chelating agent polyethylene glycol-2000, and the quality of chelating agent is 80% of metal Mn+Ni quality, adjusts with ammonium bicarbonate When the pH is 8-10, stir until viscous, add pure water under stirring to make a solution with a metal Mn+Ni ion concentration of 150g / l, and add a settling aid hydroxyformide whose mass is 4% of the mass of the metal Mn+Ni Base cellulose until the precipitation is complete, filter, and dry the precipitate to obtain the nickel-manganese precursor;

[0055] (3) Three-dimensional oblique mixing: use a three-dimensional oblique mixer to mix the nickel-manganese precursor obtained in step (2) with lithium carbonate and cationic Al 3+ and anion F - The compound was dispersed and mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com