Gallium nitride based high electron mobility transistor epitaxial structure and manufacturing method thereof

A high electron mobility, gallium nitride-based technology, applied in the field of gallium nitride-based high electron mobility transistor epitaxial structure and its manufacturing, can solve the influence of two-dimensional electron gas density and mobility rate, increase buffer layer and gate Leakage current, reducing the RF performance of transistors and other issues, to achieve the effect of improving electron mobility, increasing breakdown voltage, and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

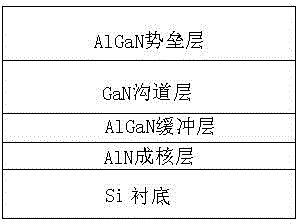

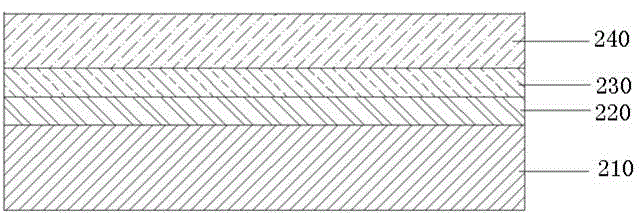

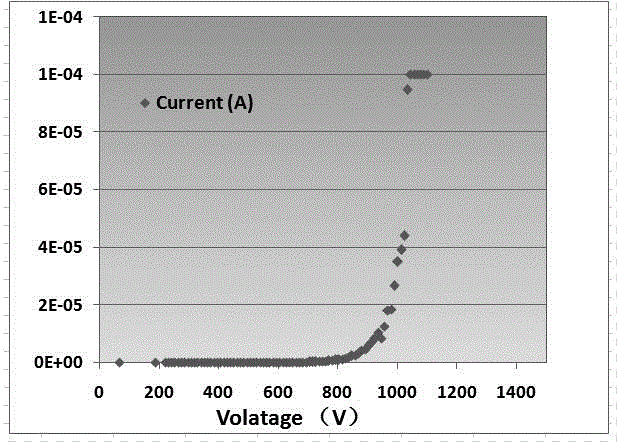

[0023] figure 2 It is a schematic diagram of the epitaxial structure for forming the GaN template layer in the present invention. It grows an AlN nucleation layer 220 , an AlGaN buffer layer 230 , and an Al-doped GaN template layer 240 sequentially on a silicon substrate 210 by MOCVD technology. The specific growth process is as follows: select the silicon (111) substrate 210, and use MOCVD technology to grow; place the silicon (111) substrate 210 in H 2 The surface is treated in the environment for 5 minutes; the temperature is kept constant, and an AlN nucleation layer 220 with a thickness of 0.3um is grown on the silicon substrate 210; an AlGaN buffer layer with a thickness of 0.2um is grown on the AlN nucleation layer 220 230; then add trimethylaluminum to the growth atmosphere to form an Al-doped GaN template layer 240 with a thickness of 2 μm, wherein the concentration of Al doping is 1×10 18 cm -3 ;Turn off gas and cool to room temperature. Then the breakdown volta...

Embodiment 2

[0025] This embodiment provides a GaN-based high electron mobility transistor, such as Figure 4 As shown, a layer of AlN nucleation layer 320 is grown on a silicon substrate 310, and then an AlGaN buffer layer 330 is grown, and then grown with an aluminum doping concentration of 1×10 16 cm -3 GaN template layer 340, then grow an AlGaN barrier layer 350 and grow a doped or non-doped GaN capping layer 360, and finally make device source, drain ohmic contact electrodes and gate electrodes ( Figure 4 not marked).

Embodiment 3

[0027] This embodiment provides another GaN-based high electron mobility transistor, such as Figure 5 As shown, an AlN nucleation layer 420 is grown on a SiC substrate 410, and then an AlGaN buffer layer 430 is grown, followed by growth of an Al doping concentration of 1×10 16 cm -3 GaN template layer 440, then grow a GaN channel layer 450 with a thickness of 50nm, grow an AlGaN barrier layer 460 and a doped or non-doped GaN cap layer 470 on the channel layer, and finally make the device source, drain ohmic contact electrode and gate electrode ( Figure 5 not marked).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com