Poly-L-lactide-caprolactone copolymer (PLCL) three-dimensional porous scaffold, PLCL and collagen (PLCL-COL) composite scaffold and preparation methods of scaffolds

A three-dimensional porous, composite scaffold technology, applied in the field of biomedicine, can solve the problems of unsuitable low-temperature rapid prototyping, preparation of scaffolds, poor cell adhesion, etc., achieve good three-dimensional structure and porosity, make up for the lack of performance, and improve hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In view of this, an embodiment of the present invention provides a method for preparing a PLCL three-dimensional porous scaffold. The PLCL three-dimensional porous scaffold is prepared by low-temperature deposition manufacturing technology, which specifically includes the following steps:

[0036] S01. CAD software is used for modeling preprocessing, Aurora software is used for layered slicing, and Cark software is used to design the printing parameters of PLCL three-dimensional porous scaffolds;

[0037] S02. Dissolving PLCL in an organic solvent to prepare a PLCL homogenate;

[0038] S03. When the temperature of the molding chamber drops to -25 to -35°C, apply the organic solvent on the molding platform, use the Cark software to set the modeling parameters, and then start printing and modeling to obtain a preformed PLCL three-dimensional porous scaffold;

[0039] S04. The PLCL three-dimensional porous scaffold preform is taken out and then freeze-dried to obtain a PLCL ...

Embodiment 1

[0068] A method for preparing a PLCL three-dimensional porous scaffold, the PLCL three-dimensional porous scaffold is prepared by low-temperature deposition manufacturing technology, specifically comprising the following steps:

[0069] S11. Modeling, layering and stacking of stents aided by computer: first, a model in STL file format is generated through CAD software modeling preprocessing; then use Aurora software to import the STL file and perform layered slices on it to generate A CLI file; finally, use the Cark software of the low-temperature rapid prototyping system to open the CLI file, design the printing parameters of the bracket and print it. CAD software was used for modeling preprocessing, Aurora software for layered slicing, and Cark software was used to design the printing parameters of PLCL three-dimensional porous scaffolds;

[0070] S12. Add PLCL accurately weighed by a high-precision electronic balance and a certain amount of 1,4-dioxane in the beaker, so tha...

Embodiment 2

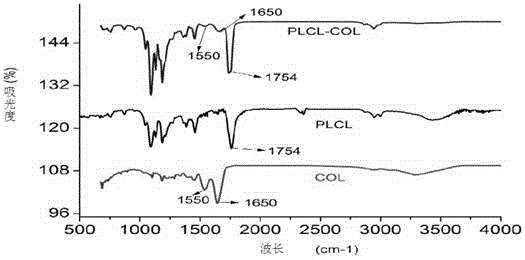

[0074] A preparation method of PLCL-COL composite support, comprising the following steps:

[0075] Q21. Provide the PLCL three-dimensional porous scaffold prepared by the above method;

[0076] Q22. Place the PLCL three-dimensional porous scaffold in 0.2% NaOH ethanol solution for 10 minutes, take it out, soak it in distilled water, and rinse it to obtain the first sample;

[0077] Q23. Place the first sample in 0.5% collagen solution (0.5g collagen dissolved in 100mL 0.3% acetic acid solution) for 4 hours, soak in distilled water, rinse the excess collagen solution, and obtain the PLCL-COL composite stent preform;

[0078] Q24. Freeze-drying the PLCL-COL composite scaffold preform to prepare the PLCL-COL composite scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com