A kind of preparation method of polyurethane adhesive for wood

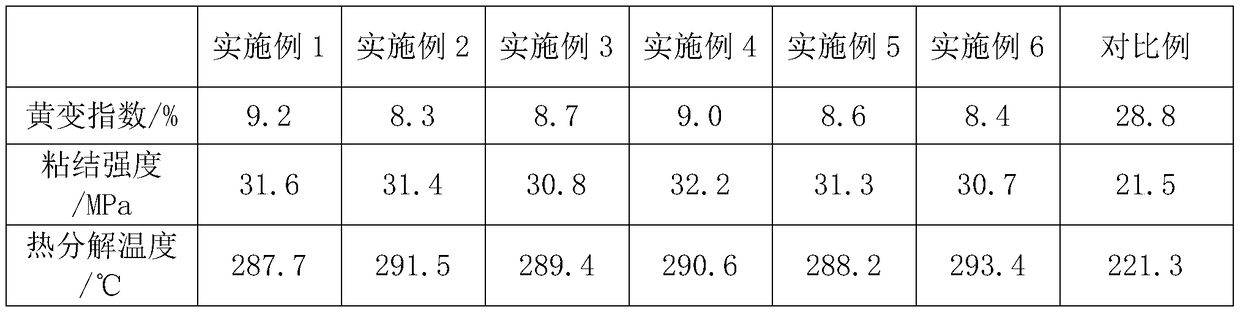

A polyurethane adhesive, wood technology, applied in the direction of polyurea/polyurethane adhesives, lignocellulosic material adhesives, adhesives, etc., can solve the problems of poor resistance to yellowing and aging, insufficient bonding strength, and insufficient environmental protection. , to achieve good strength and toughness, improve yellowing and aging resistance, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of polyurethane adhesive for wood, its step is as follows:

[0025] (1) After the mulberry fiber is ground, cross a 60-mesh sieve, place it in a constant temperature drying oven and dry it at 90°C for 5 hours, add a mass concentration of 2% sodium hydroxide solution, the weight of the mulberry fiber and sodium hydroxide solution The volume ratio is 1:20g / mL, stirred in a water bath at 90°C for 2 hours, filtered after discharge, washed the filter residue with water until the filtrate is neutral, and dried in a constant temperature drying oven at 90°C to constant weight to obtain alkalized mulberry bark fiber;

[0026] (2) Add mica iron oxide powder with a weight ratio of 2:3 and the alkalized mulberry fiber obtained in step (1) into ethanol and ultrasonically vibrate for 1 hour to obtain a mixed solution, and hydrolyze KH-570 with deionized water for 30 minutes After that, add it to the aforementioned mixture, stir it magnetically at 85°C for 1 ho...

Embodiment 2

[0029] The preparation method of polyurethane adhesive for wood, its step is as follows:

[0030] (1) After the mulberry fiber is ground, cross a 60-mesh sieve, place it in a constant temperature drying oven and dry it at 90°C for 5 hours, add a mass concentration of 2% sodium hydroxide solution, the weight of the mulberry fiber and sodium hydroxide solution The volume ratio is 1:20g / mL, stirred in a water bath at 90°C for 2 hours, filtered after discharge, washed the filter residue with water until the filtrate is neutral, and dried in a constant temperature drying oven at 90°C to constant weight to obtain alkalized mulberry bark fiber;

[0031] (2) Add mica iron oxide powder with a weight ratio of 2:3 and the alkalized mulberry fiber obtained in step (1) into ethanol and ultrasonically vibrate for 1 hour to obtain a mixed solution, and hydrolyze KH-570 with deionized water for 30 minutes After that, add it to the aforementioned mixture, stir it magnetically at 85°C for 1 ho...

Embodiment 3

[0034] The preparation method of polyurethane adhesive for wood, its step is as follows:

[0035] (1) After the mulberry fiber is ground, cross a 60-mesh sieve, place it in a constant temperature drying oven and dry it at 90°C for 5 hours, add a mass concentration of 2% sodium hydroxide solution, the weight of the mulberry fiber and sodium hydroxide solution The volume ratio is 1:20g / mL, stirred in a water bath at 90°C for 2 hours, filtered after discharge, washed the filter residue with water until the filtrate is neutral, and dried in a constant temperature drying oven at 90°C to constant weight to obtain alkalized mulberry bark fiber;

[0036] (2) Add mica iron oxide powder with a weight ratio of 2:3 and the alkalized mulberry fiber obtained in step (1) into ethanol and ultrasonically vibrate for 1 hour to obtain a mixed solution, and hydrolyze KH-570 with deionized water for 30 minutes After that, add it to the aforementioned mixture, stir it magnetically at 85°C for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com