A kind of high-purity tantalum powder and its preparation method

A tantalum powder and high-purity technology, applied in the field of high-purity tantalum powder and its preparation, can solve problems such as limitations of design process parameters, high content of magnesium and hydrogen in the final product, sintering and growth of tantalum particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

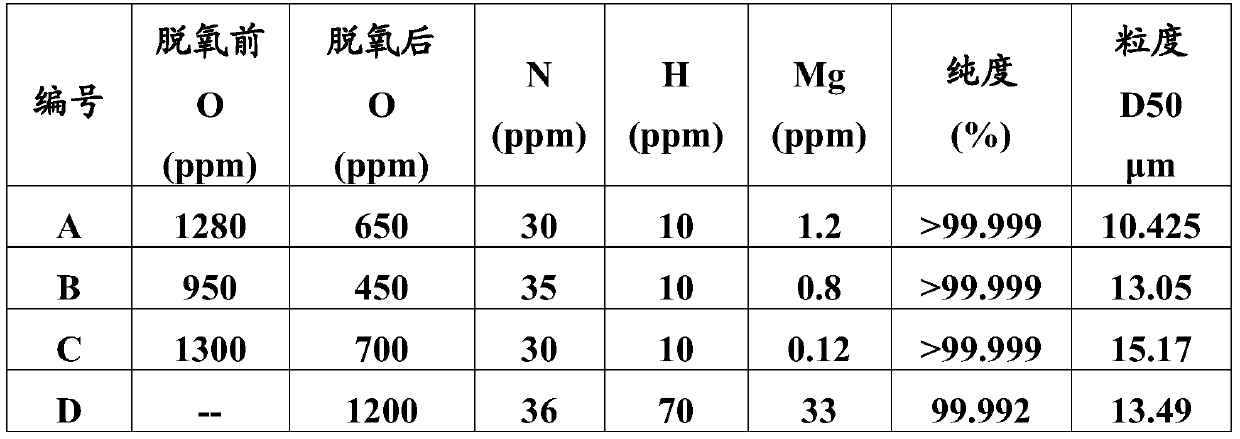

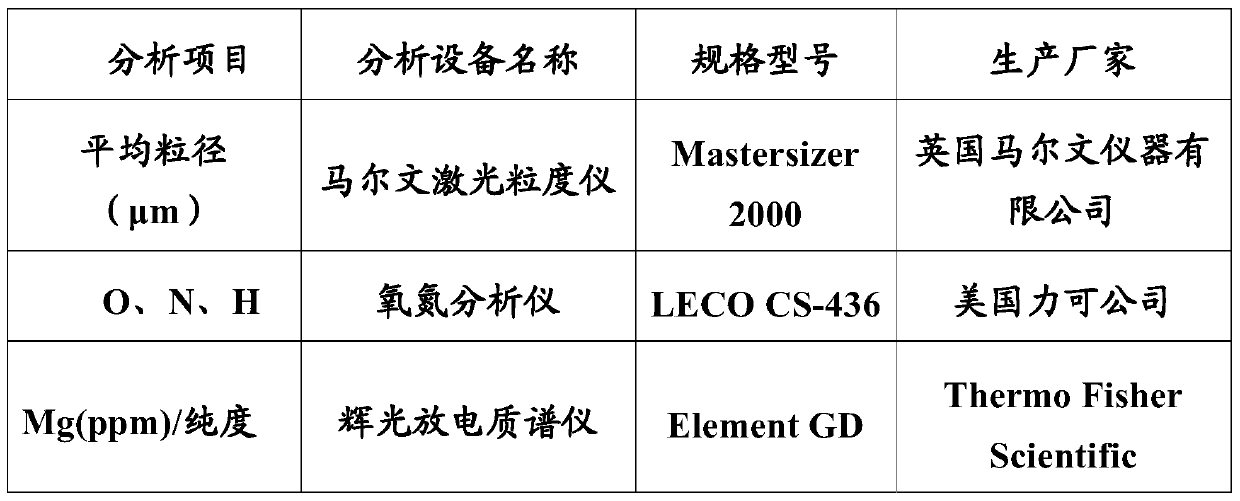

Embodiment 1

[0035] Embodiment 1: Select sodium-reduced tantalum powder as raw material, carry out layering, sintering, electron beam melting to form tantalum ingot, and carry out hydrogenation treatment on the tantalum ingot. The tantalum scrap obtained after hydrogenating the tantalum ingot is crushed by ball milling and passed through a 500-mesh sieve. The tantalum powder sieved by the ball mill is used with HNO 3 Mixed acid with HF (HNO 3 , HF and water volume ratio is 4:1:20) pickling to remove metal impurities, drying and sieving (put the above tantalum powder in a closed furnace and heat it to 900°C for 180 minutes, then cool it out of the furnace and sieve After sieving, the oxygen content analysis is carried out, and the analysis results are shown in Table 1. Then the tantalum powder is mixed with 1% magnesium powder based on the weight of the tantalum powder, and then heated to 700 ° C in a closed furnace with argon, and kept for 2 hours. Then cool out of the furnace, wash with...

Embodiment 2

[0036] Example 2: Select sodium-reduced tantalum powder as raw material to form tantalum ingots by layering, sintering, and electron beam smelting, and then hydrogenate the tantalum ingots. The tantalum scrap obtained after hydrogenating the tantalum ingot is crushed by ball milling and passed through a 500-mesh sieve. Ball milled and sieved powder with HNO 3 Mixed acid with HF (HNO 3 , HF and water volume ratio is 4:1:20) pickling to remove metal impurities, drying and sieving. Place the above tantalum powder in a closed furnace, fill it with argon and heat it to 900°C for 180 minutes, then cool it out of the furnace and sieve it. After sieving, the oxygen content was analyzed, and the analysis results are shown in Table 1. Then mix tantalum powder with magnesium powder of 1% of the weight of tantalum powder, then heat it to 750°C in a closed furnace filled with argon, keep it warm for 2 hours, then cool it out of the furnace, wash with nitric acid to remove excess magnesi...

Embodiment 3

[0037] Embodiment 3: select sodium-reduced tantalum powder as raw material, carry out layering, sintering, and electron beam melting to form tantalum ingot, and then hydrogenate the tantalum ingot. The tantalum scrap obtained after hydrogenating the tantalum ingot is crushed by ball milling and passed through a 500-mesh sieve. Ball milled and sieved powder with HNO 3 Mixed acid with HF (HNO 3 , HF and water volume ratio is 4:1:20) pickling to remove metal impurities, drying and sieving. Place the above tantalum powder in a closed furnace, fill it with argon and heat it to 900°C for 180 minutes, then cool it out of the furnace and sieve it. After sieving, the oxygen content was analyzed, and the analysis results are shown in Table 1. Then mix tantalum powder with magnesium powder of 1% of the weight of tantalum powder, then heat it to 700°C in a closed furnace filled with argon, keep it warm for 2 hours, then cool it out of the furnace, wash with nitric acid to remove excess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com