Preparation method for shell-core type carbon-coated metal sulfide nano-composite particles and application of particles

A technology of nanocomposite particles and metal nanoparticles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, long preparation cycle, and reduced capacity, and achieve the goal of preparation process Simple, low cost of raw materials, and the effect of inhibiting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

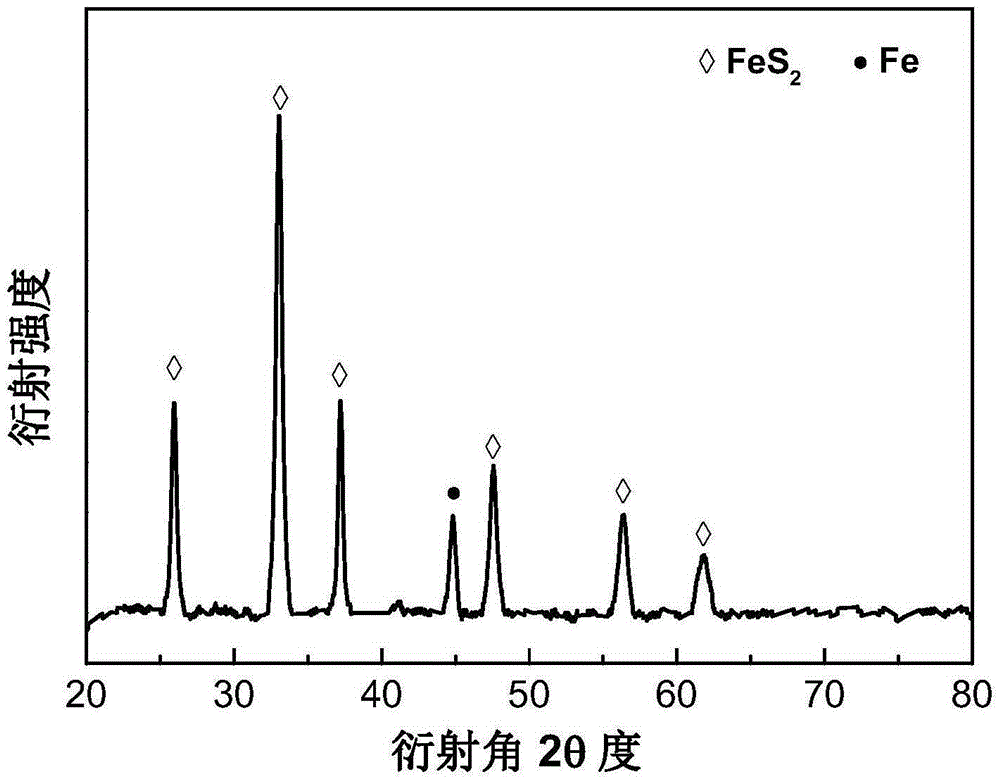

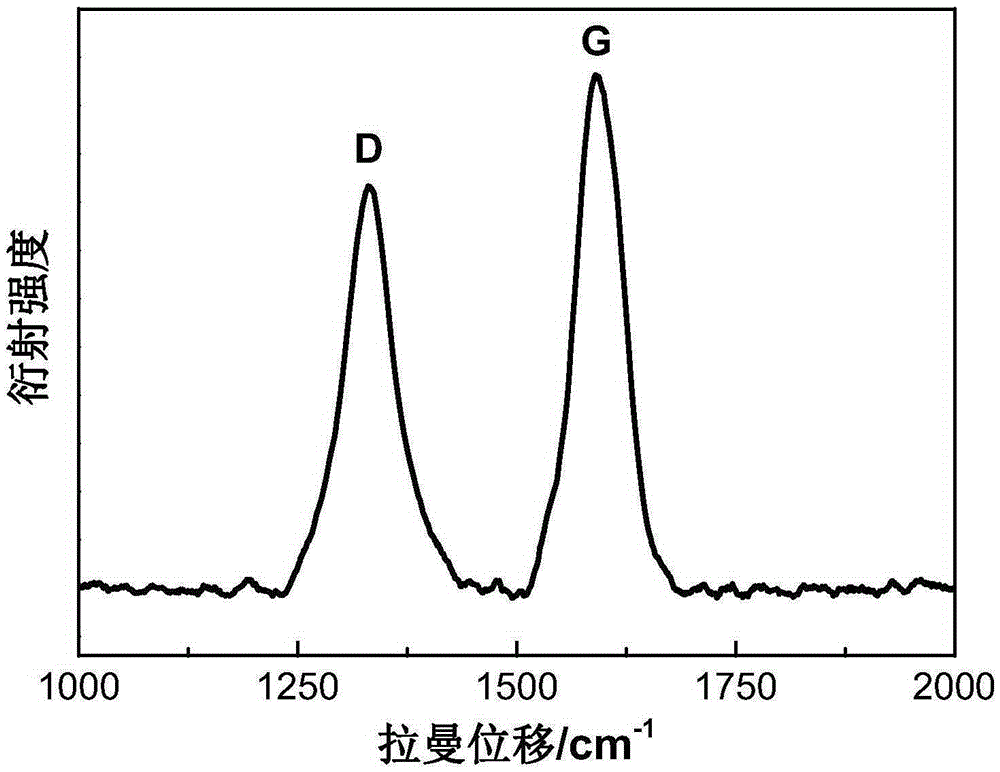

[0042] Take about 40g of iron block and put it into the anode of the powder generation chamber of the automatic control direct current arc metal nano powder production equipment to evaporate, and at the same time, feed methane and argon with a ratio of 3:4 to obtain the carbon-coated iron nano particle precursor; Mix this precursor with sulfur powder at a mass ratio of 2:3 in a glove box (to ensure an anhydrous and oxygen-free environment) and put it into a high-pressure sealed reactor, which is heated to 400°C under the protection of 0.05MPa argon. Heat treatment for 1.5h, and cool to room temperature to obtain a carbon-coated iron sulfide nanocomposite material.

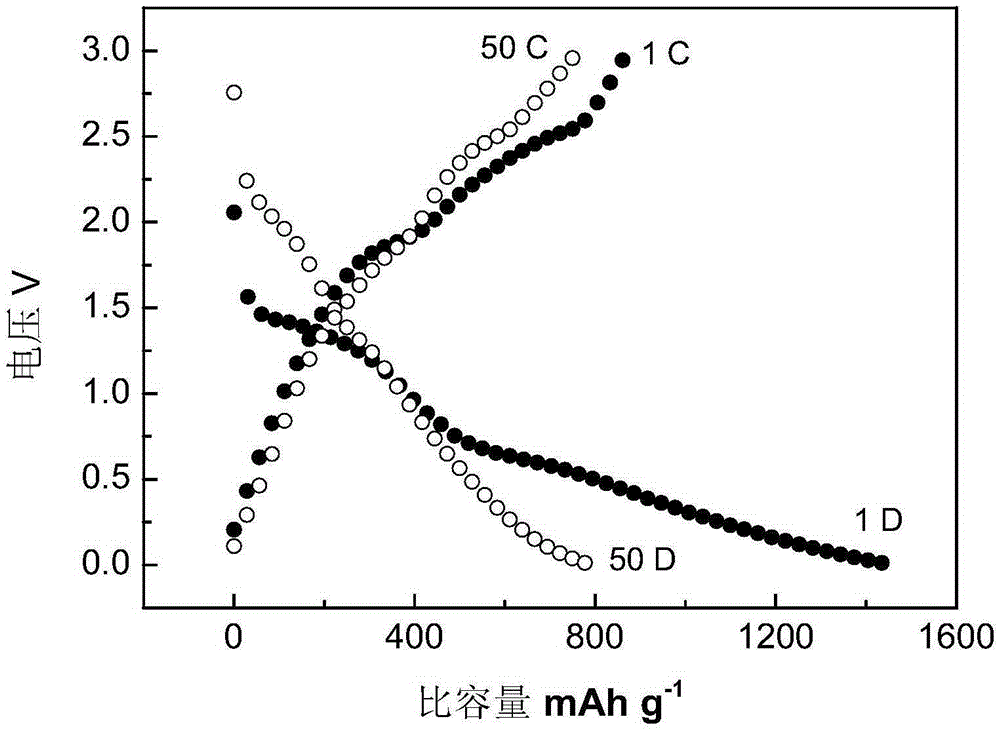

[0043] The above-mentioned carbon-coated metal sulfide nanocomposite material is made into a lithium ion electrode sheet. Wherein the electrode sheet is uniformly mixed with 80% carbon-coated iron sulfide nanocomposites, 10% Ketjen black and 10% polyvinylidene fluoride (PVDF) binder by mass ratio, and an appropriat...

Embodiment 2

[0049] Take about 20g of iron powder and 15g of carbon powder and mix them evenly, press them into a block, put it into the anode of the powder generation room of the automatic control DC arc metal nano powder production equipment, evaporate it, and inject 0.06MPa helium gas at the same time to obtain carbon coating Iron nanoparticle precursor; mix this precursor with sulfur powder in a glove box at a mass ratio of 1:3 and put it in a sealed reactor. The reactor is heated to 500°C under the protection of 0.01MPa nitrogen for heat treatment for 1h, and cooled to room temperature to obtain carbon-coated iron sulfide nanocomposites.

Embodiment 3

[0051] Take about 80g of iron powder and put it into the graphite crucible, add 20-40ml of ethanol, put the graphite crucible into the anode of the powder generation chamber of the automatic control DC arc metal nano powder production equipment to evaporate, and at the same time, pass in 0.01MPa neon gas Obtain the precursor of carbon-coated iron nanoparticles; this precursor is mixed with sulfur powder at a mass ratio of 1:1 in the glove box and then placed in a high-pressure sealed reactor, which is heated to 250 °C under the protection of 0.08 MPa helium ℃ for 3 hours, cooled to room temperature to obtain carbon-coated iron sulfide nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com