Synthetic method of vitamin A palmitate

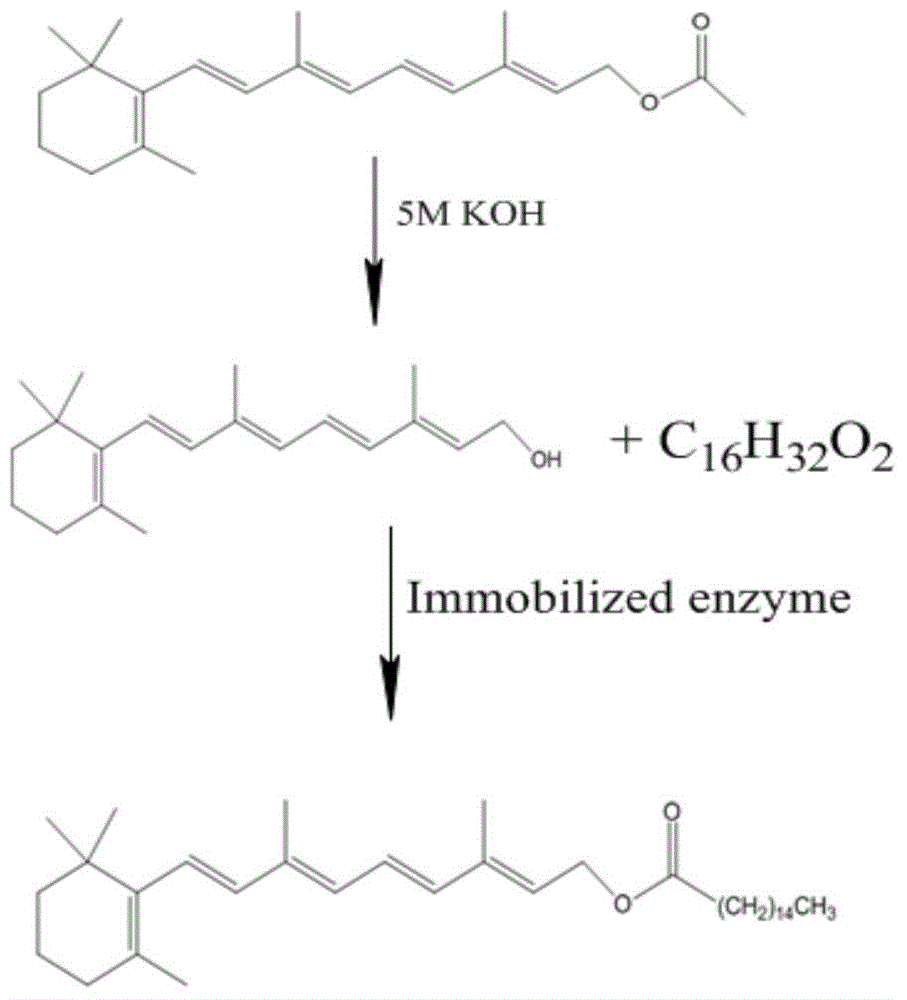

A technology of palmitate and synthesis method, applied in the direction of recombinant DNA technology, immobilized on/in organic carrier, using carrier to introduce foreign genetic material, etc., can solve separation difficulties, conversion rate can not meet the requirements of industrial production, etc. problem, to achieve the effect of less dosage, short catalytic reaction time and high immobilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

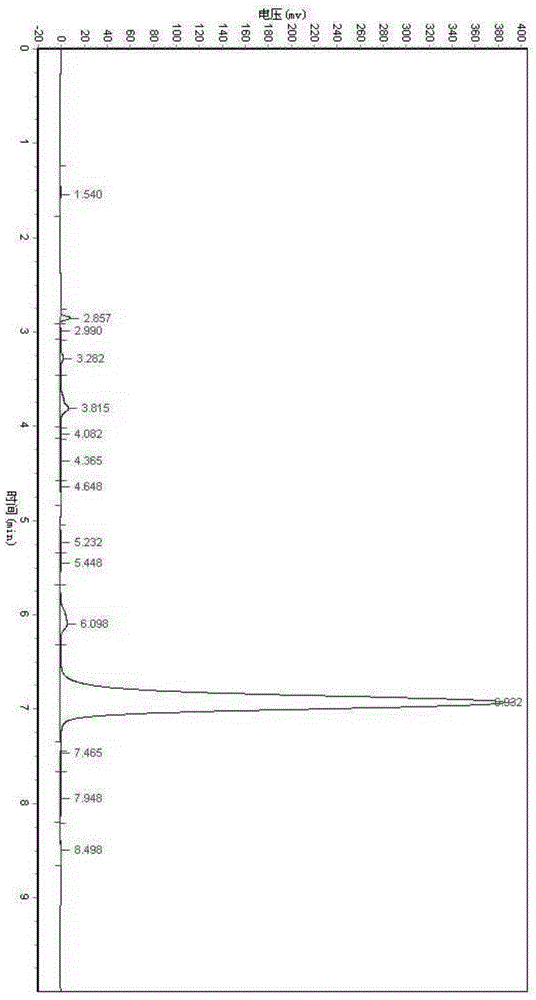

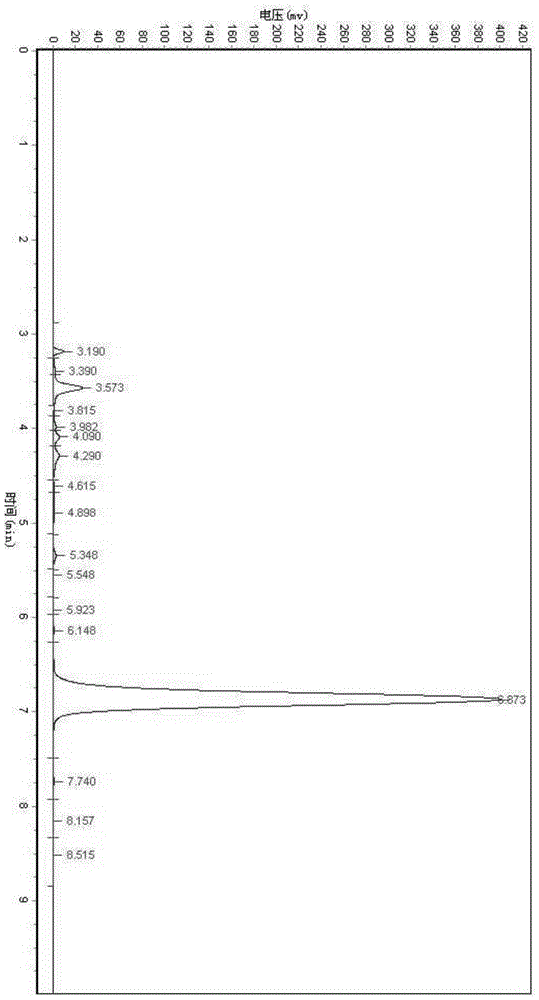

Image

Examples

Embodiment 1

[0035] Embodiment 1: macroporous adsorption resin carries out pretreatment

[0036] Rinse the macroporous resin AB-8 (purchased from Tianjin Nankai Hecheng Technology Co., Ltd.) with distilled water, soak in distilled water for 24 hours, remove organic impurities and insoluble matter; soak in 95% ethanol aqueous solution for 24 hours, then rinse with distilled water Resin until there is no alcohol smell, the resin after pretreatment is preserved in distilled water for subsequent use.

Embodiment 2

[0037] The preparation of embodiment 2 enzyme powder

[0038] (1) Construction and cultivation of engineering bacteria

[0039] The lipase exists in Pichia pastoris cells, and the lipase gene is derived from a strain of Candida antarctica (Candida antarctica) ZJB09193, which is now preserved in the Wuhan General Culture Collection Center with a preservation number of CCTCCM2010263, which has been published in the literature "non- Screening of aqueous lipase and its application in the synthesis of vitamin C palmitate, Zhang Qiuhua, 2012, published in "Master's Thesis".

[0040] The expression vector pPICZαA-CALB (the nucleotide sequence of the Candida antarctica ZJB09193 lipase B gene is shown in SEQ ID NO: 1) containing the gene encoding Candida antarctica ZJB09193 lipase B was linearized by SacI , electrotransformed into Pichia pastoris (Pichiapastoris) X33 (purchased from Invitrogen), spread on a YPD plate containing Zeocin (bleomycin) at a final concentration of 100 μg / μL,...

Embodiment 3

[0066] Embodiment 3: the preparation of immobilized lipase

[0067] Prepare Na at pH 6.0 with distilled water 2 HPO 4 - citric acid buffer (Na 2 HPO 4 and the molar concentration of citric acid are respectively 0.05M and 0.025M), take by weighing the lipase enzyme powder that 16g embodiment 2 method prepares and dissolve to 1LNa 2 HPO 4 - Prepare the enzyme solution in citrate buffer. Accurately weigh 0.6g (wet weight) of the macroporous adsorption resin AB-8 pretreated in Example 1 and mix it with the enzyme solution at a mass volume ratio of 1:20, and shake and adsorb in a water bath shaker at 35°C and 180rpm. After 2 hours of immobilization (i.e., adsorption saturation), the supernatant was removed by suction filtration, and the adsorbed macroporous resin was washed twice with distilled water (to remove unadsorbed free enzymes on the surface of the carrier), and dried at room temperature (22°C). 0.3 g of the immobilized enzyme product was obtained, and stored in a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com