Fluorocarbon paint high in fluorine content and preparation method thereof

A technology of fluorine content and fluorocarbon paint, applied in the direction of coating, etc., can solve the problem of low fluorine content of fluorocarbon, and achieve the effect of improving resin fluorine content, excellent weather resistance, and excellent anti-fouling property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

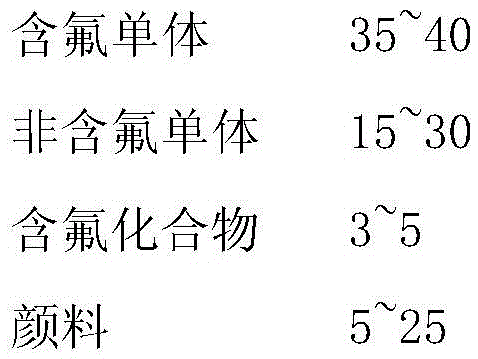

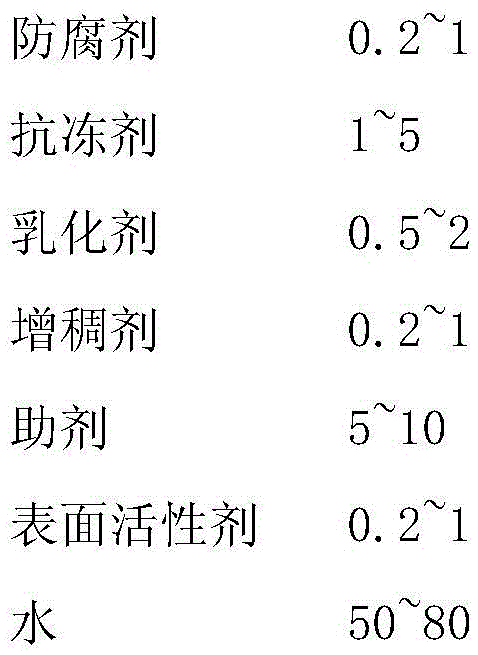

Method used

Image

Examples

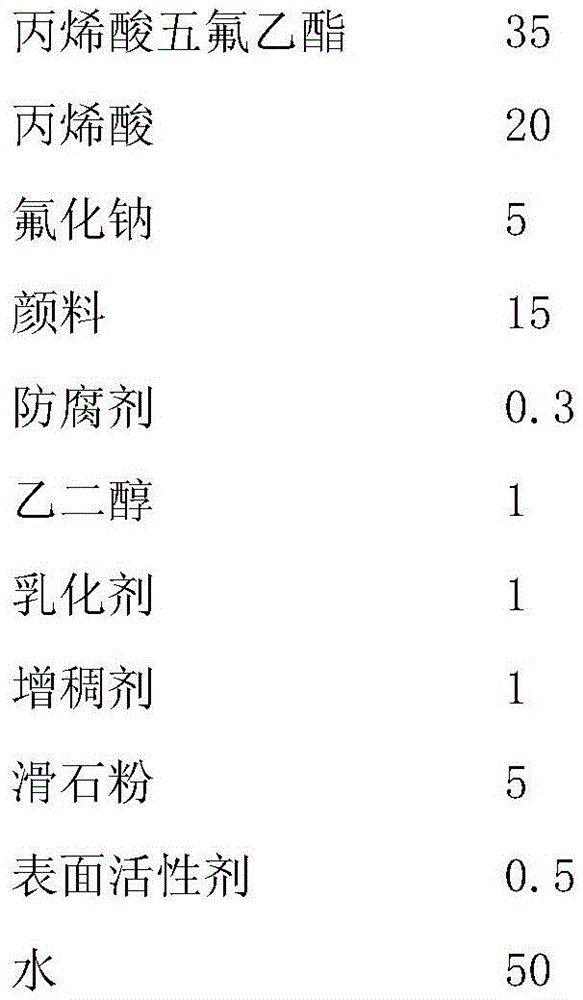

Embodiment 1

[0027] According to the following ratio of mass parts:

[0028]

[0029] a. After mixing and stirring pentafluoroethyl acrylate and acrylic acid in an anhydrous container, add sodium fluoride to the system, and stir at a speed of 300 r / min;

[0030] b. Add an emulsifier to the mixture obtained in a, and control the temperature at 50° C. at a speed of 800 r / min, and stir for 16 hours to obtain a fluoropolymer seed resin;

[0031] c. Add preservatives, thickeners, ethylene glycol, and pigments to the fluoropolymer seed resin, and stir evenly at 800r / min;

[0032] d. Add surfactant and water to the system, stir until uniform emulsion, add talc powder, adjust the rotation speed to 1500r / min and stir until the fineness is less than 100um to obtain fluorocarbon paint 1-1.

Embodiment 2

[0034] According to the following ratio of mass parts:

[0035]

[0036]

[0037] a. After mixing pentafluoroethyl methacrylate vinyl ether evenly in an anhydrous container, add silver fluoride to the system, and stir evenly at a speed of 400r / min;

[0038] b. Add an emulsifier to the mixture obtained in a, and control the temperature at 40° C. at a speed of 600 r / min, and stir for 14 hours to obtain a fluoropolymer seed resin;

[0039] c. Add preservatives, thickeners, propylene glycol, and pigments to the fluoropolymer seed resin, and stir evenly at a rotating speed of 800r / min;

[0040] d. Add surfactant and water to the system, stir until uniform emulsion, add barium sulfate, adjust the rotation speed to 1300r / min and stir until the fineness is less than 100um to obtain fluorocarbon paint 1-2.

Embodiment 3

[0042] According to the following ratio of mass parts:

[0043]

[0044] a. After mixing trifluoroethyl acrylate and vinyl acetate in an anhydrous container and stirring evenly, add boron trifluoride to the system, and stir evenly at a speed of 200r / min;

[0045] b. Add an emulsifier to the mixture obtained in a, and control the temperature at 90° C. at a speed of 800 r / min, and stir for 10 hours to obtain a fluoropolymer seed resin;

[0046] c. Add preservatives, thickeners, ethylene glycol, and pigments to the fluoropolymer seed resin, and stir evenly at 800r / min;

[0047] d. Add surfactant and water to the system, stir until uniform emulsion, add superfine ground calcium carbonate, adjust the rotation speed to 1500r / min and stir until the fineness is less than 100um, to obtain fluorocarbon paint 1-3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap