Preparation method of oxide dilute magnetic semiconductor nanodot array with high saturation magnetization

A nano-dot array, dilute magnetic semiconductor technology, used in ion implantation plating, metal material coating process, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Firstly, the double-pass porous ultra-thin anodized aluminum template was prepared by two-step anodic oxidation method: the high-purity aluminum sheet (99.99%) was cleaned and polished as the anode, and the graphite was used as the cathode for the first anodic oxidation. The electrolyte is 0.3mol / L oxalic acid aqueous solution, the oxidation voltage is 30-60V, specifically 40V, the temperature is 0-10°C, specifically 0°C, and the first oxidation time is 2-5h, specifically 2h. After the first anodic oxidation is completed, put the aluminum sheet oxidized for the first time face down in a mixture of phosphoric acid, chromic acid and water at a water bath temperature of 60°C, soak for 4 hours to remove the porous alumina layer after the first oxidation, The mass percentage of phosphoric acid in the mixed solution is 6.0%, and the mass percentage of chromic acid is 1.8%; the conditions of the second oxidation are the same as those of the first oxidation, but the oxidation ti...

Embodiment 2

[0062] The preparation method is the same as that of Example 1, except that the alumina template is soaked in a 5% by mass phosphoric acid solution at 30° C. for 60 minutes.

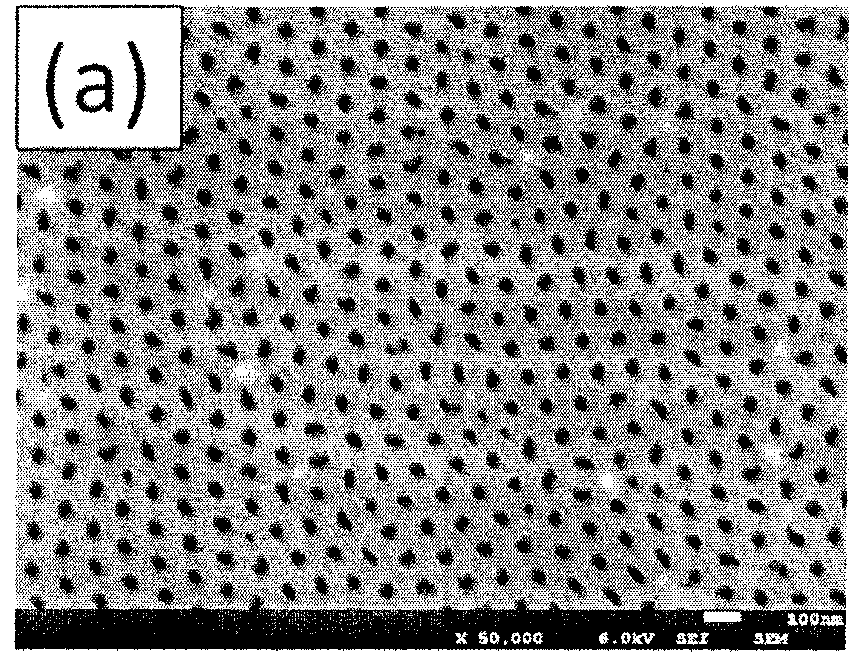

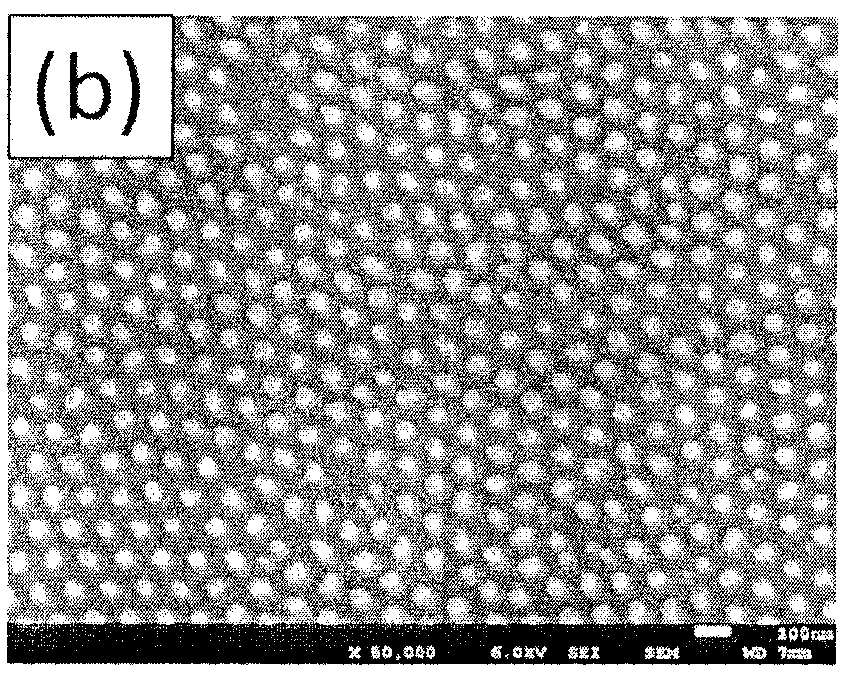

[0063] image 3 with Figure 4 The ultra-thin porous anodized aluminum template and (In 0.95 Fe 0.05 ) 2 o 3 The scanning electron microscope image of the nano-dot array shows that the obtained nano-dot array and the holes of the alumina template are distributed in hexagonal symmetry, and the diameter of the nano-dot is basically the same as the template pore size. The average diameter of the prepared nano-dot array is 65nm, and the height is 40nm. The nanodot pitch is 105nm.

Embodiment 3

[0065] Preparation method is identical with embodiment 1, and difference is: (In 0.95 Fe 0.05 ) 2 o 3 When the ceramic target is prepared, the powder calcining temperature is 850°C, and the target sintering temperature is 1050°C; moreover, the alumina template is immersed in a 5% by mass phosphoric acid solution at 30°C for 75 minutes.

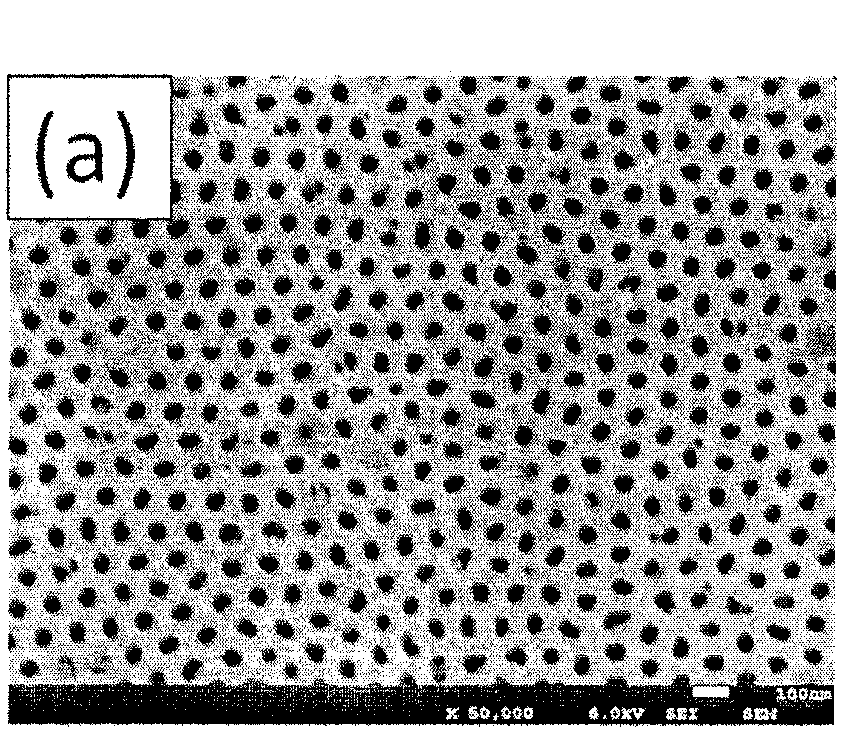

[0066] Figure 5 with Image 6 Respectively the ultra-thin porous anodized aluminum template and (In 0.95 Fe 0.05 ) 2 o 3 The scanning electron microscope image of the nano-dot array shows that the obtained nano-dot array and the holes of the alumina template are distributed hexagonally symmetrically, and the diameter of the nano-dot is basically the same as the template pore size. The average diameter of the prepared nano-dot array is 77nm, and the height is 40nm. The nanodot pitch is 105nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com