Coal gasification sewage comprehensive treatment method

A coal gasification sewage and comprehensive treatment technology, applied in the direction of multi-stage water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To ensure compliance with emission standards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

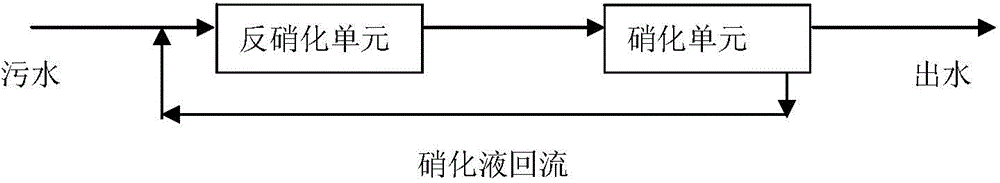

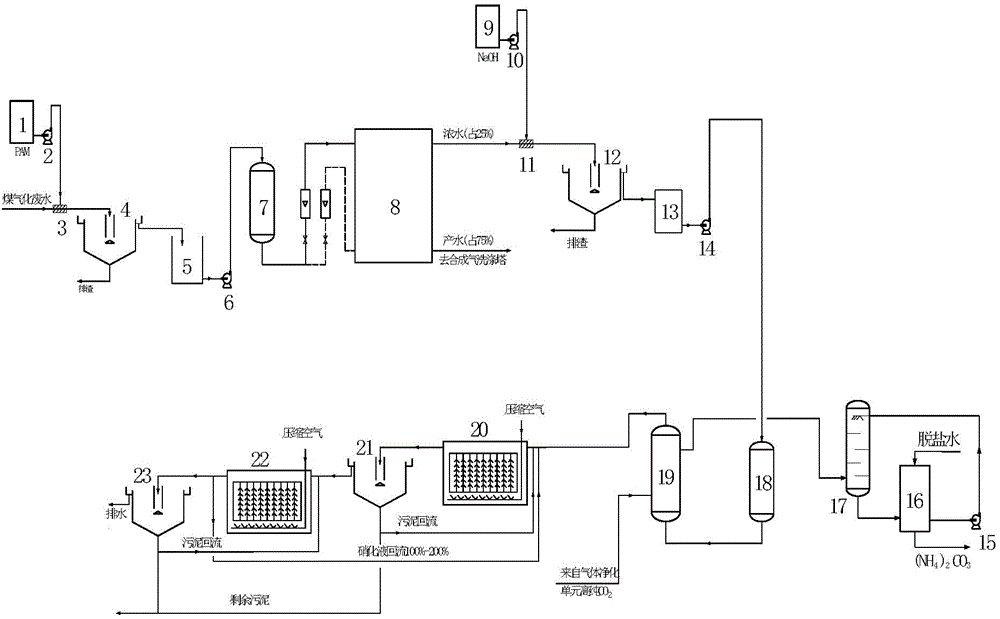

Method used

Image

Examples

Embodiment 1

[0090] With a gas production capacity of 100,000 m3 / h coal gasification unit as an example, assuming that there is no water loss during the washing process, the amount of desalted water in the washing tower is 100m 3 / h, the sewage discharge is 100m 3 / h. In the discharged sewage, the conductivity is 4000μS / cm, the total hardness is 1000mg / L, the COD is 500mg / L, the ammonia nitrogen is 300mg / L, and the chloride ion is 300mg / L.

[0091] The first step is flocculation and sedimentation. Add 1-2ppm polyacrylamide to the sewage, and after the pipeline mixer fully mixes and reacts with suspended matter such as fly ash in the sewage, it enters the sedimentation tank through the diversion pipe of the radial flow sedimentation tank, and the sedimentation time is 4 hours. Suspended matter settles to the bottom of the pond, and the slag is discharged every 4 hours, and sent to the ash yard.

[0092] The second step is security filtering. Sewage to remove suspended solids is filtere...

Embodiment 2

[0100] With gas production of 2 million m 3 / h coal gasification unit as an example, assuming that there is no water loss during the washing process, the amount of desalinated water in the washing tower is 2000m 3 / h, the sewage discharge is 2000m 3 / h. In the discharged sewage, the conductivity is 4500μS / cm, the total hardness is 1100mg / L, the COD is 500mg / L, the ammonia nitrogen is 300mg / L, and the chloride ion is 400mg / L.

[0101] The first step is flocculation and sedimentation. Add 1-2ppm polyacrylamide to the sewage, and after the pipeline mixer fully mixes and reacts with suspended solids such as fly ash in the sewage, it enters the sedimentation tank through the diversion pipe of the radial flow sedimentation tank, and the sedimentation time is 3 hours. Suspended matter settles to the bottom of the pool, and the slag is discharged every 4 hours, and sent to the gasification slag field.

[0102] The second step is security filtering. Sewage to remove suspended soli...

Embodiment 3

[0111] With a gas production capacity of 500,000 m 3 / h coal gasification unit as an example, assuming that there is no water loss during the washing process, the desalinated water volume of the washing tower is 500m 3 / h, the sewage discharge is 500m 3 / h. In the discharged sewage, the conductivity is 3500μS / cm, the total hardness is 900mg / L, the COD is 500mg / L, the ammonia nitrogen is 300mg / L, and the chloride ion is 250mg / L.

[0112] The first step is flocculation and sedimentation. Add 1-2ppm polyacrylamide to the sewage, and after the pipeline mixer fully mixes with the suspended matter such as fly ash in the sewage, it enters the sedimentation tank through the diversion pipe of the radial flow sedimentation tank, and the sedimentation time is 5 hours. Suspended matter settles to the bottom of the pool, and the slag is discharged every 4 hours, and sent to the gasification slag field.

[0113] The second step is security filtering. Sewage to remove suspended solids i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com