Surface modification method of anti-oxidation nano-calcium carbonate for silicone sealant

A technology of nano-calcium carbonate and silicone sealant, which is applied in the direction of chemical instruments and methods, adhesives, non-polymer adhesive additives, etc. In order to solve the problem of poor anti-oxidation property of additives, achieve good thixotropic performance and processing performance, low production cost and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

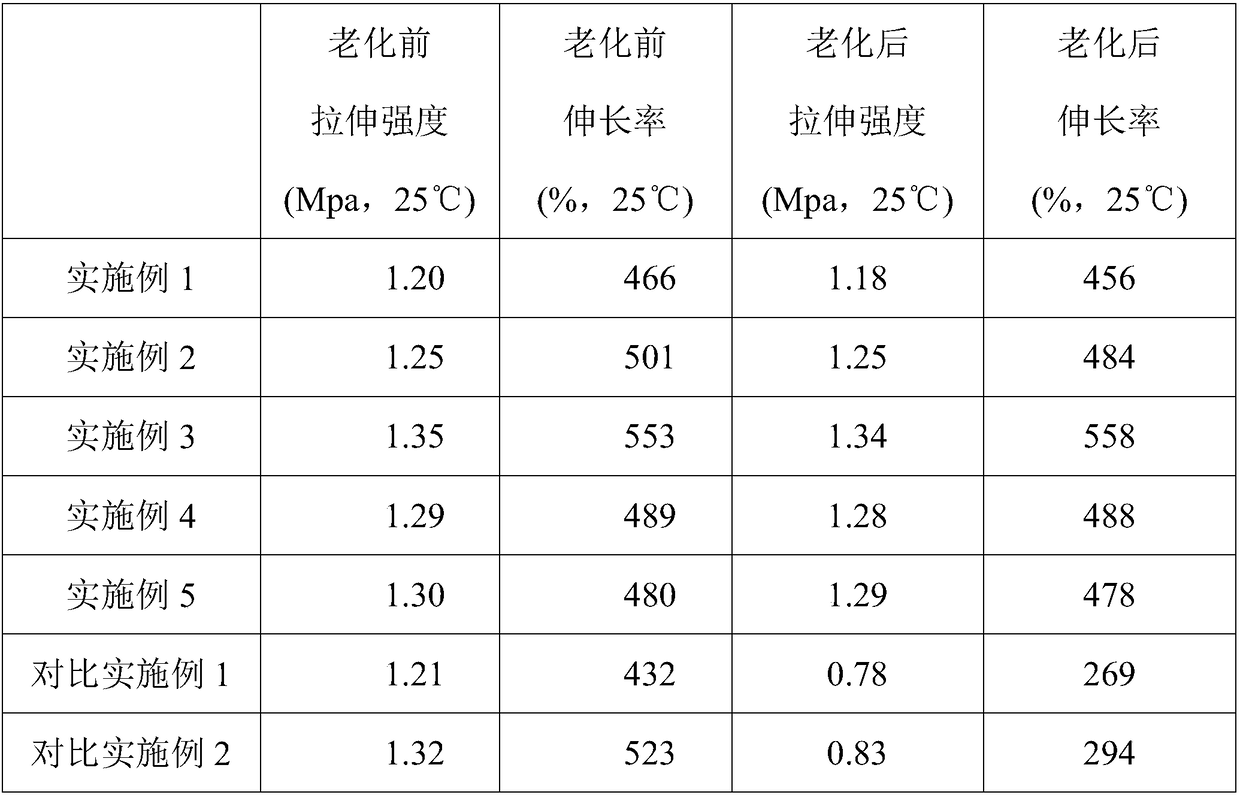

Examples

Embodiment 1

[0031] Nano-calcium carbonate slurry is processed, and the processing method is as follows:

[0032] The newly prepared pH is 6.8, BET specific surface area is 25.1m 2 / g, mass concentration is 10% nano-calcium carbonate suspension is added in the reaction tower, high-speed stirring, after mixing, pass into steam heating temperature to 80 ℃, and constant temperature; Then add 2.5% (calcium carbonate dry basis) fatty acid Mixed saponification solution with iron-sodium diethylenetriaminepentaacetate complex, wherein the mass ratio of fatty acid to iron-sodium diethylenetriaminepentaacetate complex is 9:1, the fatty acid is stearic acid, and the saponification agent is selected Sodium hydroxide, its addition is 17% of the total weight of fatty acid and diethylene triamine pentaacetate ferric-sodium complex, stirred for 40 minutes, stopped steam heating, squeezed the treated nano-calcium carbonate slurry, and entered the chain Drying treatment with a dryer, the moisture content o...

Embodiment 2

[0034] Nano-calcium carbonate slurry is processed, and the processing method is as follows:

[0035] The newly prepared pH is 6.9, BET specific surface area is 30.2m 2 / g, the nanometer calcium carbonate suspension that mass concentration is 10% is added in the reaction tower, stirs at a high speed, after mixing, feeds steam heating temperature to 80 ℃, and constant temperature; Then add 3.0% (calcium carbonate dry basis) fatty acid Mixed saponification solution with iron-sodium diethylenetriaminepentaacetate complex, wherein the mass ratio of fatty acid to iron-sodium diethylenetriaminepentaacetate complex is 9:1, the fatty acid is stearic acid, and the saponification agent is selected Sodium hydroxide, its addition is 17% of the total weight of fatty acid and diethylene triamine pentaacetate ferric-sodium complex, stirred for 40 minutes, stopped steam heating, squeezed the treated nano-calcium carbonate slurry, and entered the chain Drying treatment with a dryer, the moistu...

Embodiment 3

[0037] Nano-calcium carbonate slurry is processed, and the processing method is as follows:

[0038] The newly prepared pH is 6.8, BET specific surface area is 34.7m 2 / g, the nanometer calcium carbonate suspension that mass concentration is 10% is added in the reaction tower, stirs at a high speed, after mixing, feeds steam heating temperature to 80 ℃, and constant temperature; Then add 3.5% (calcium carbonate dry basis) fatty acid Mixed saponification solution with iron-sodium diethylenetriaminepentaacetate complex, wherein the mass ratio of fatty acid to iron-sodium diethylenetriaminepentaacetate complex is 9:1, the fatty acid is stearic acid, and the saponification agent is selected Sodium hydroxide, its addition is 17% of the total weight of fatty acid and diethylene triamine pentaacetate ferric-sodium complex, stirred for 40 minutes, stopped steam heating, squeezed the treated nano-calcium carbonate slurry, and entered the chain Drying treatment with a dryer, the moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com