Method for preparing BCNO light-emitting nanosheet

A technology of nanosheets and boric acid, which is applied in the field of preparation of multifunctional BCNO nanosheets, can solve the problems of environmental pollution, unfavorable green synthesis and industrial application of BCNO phosphors, poor controllability of urea combustion method, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Put 0.02 mole of boric acid and 0.04 mole of dicyandiamide into the oven for heating pretreatment respectively in proportion. The heating temperature is 120°C and the heating time is 5 hours. After the heating is completed, it is naturally cooled to room temperature; For boric acid: dicyandiamide = 1:2,

[0028] Step 2: Put the pretreated boric acid and dicyandiamide into the reactor immediately, then add 15ml of ethylene glycol, and stir at 50°C for 5 hours; then raise the temperature of the solution to 90°C, Evaporation of the diol solvent, the precursor of the BCNO nanosheet is gradually precipitated from the solvent, and the solution is evaporated to dryness to obtain the precursor of the BCNO nanosheet;

[0029] Step 3: Put the BCNO nanosheet precursor prepared in the previous step into a muffle furnace for sintering. The muffle furnace is raised to 625°C at a rate of 5°C per minute, and sintered at this temperature for 5 hours. After sintering, cool natur...

Embodiment 2

[0031] Other steps are the same as in Example 1, except that the volume of ethylene glycol in step 2 is changed from 15ml to 20ml.

Embodiment 3

[0033] Other steps are the same as in Example 1, except that the volume of ethylene glycol in step 2 is changed from 15ml to 25ml.

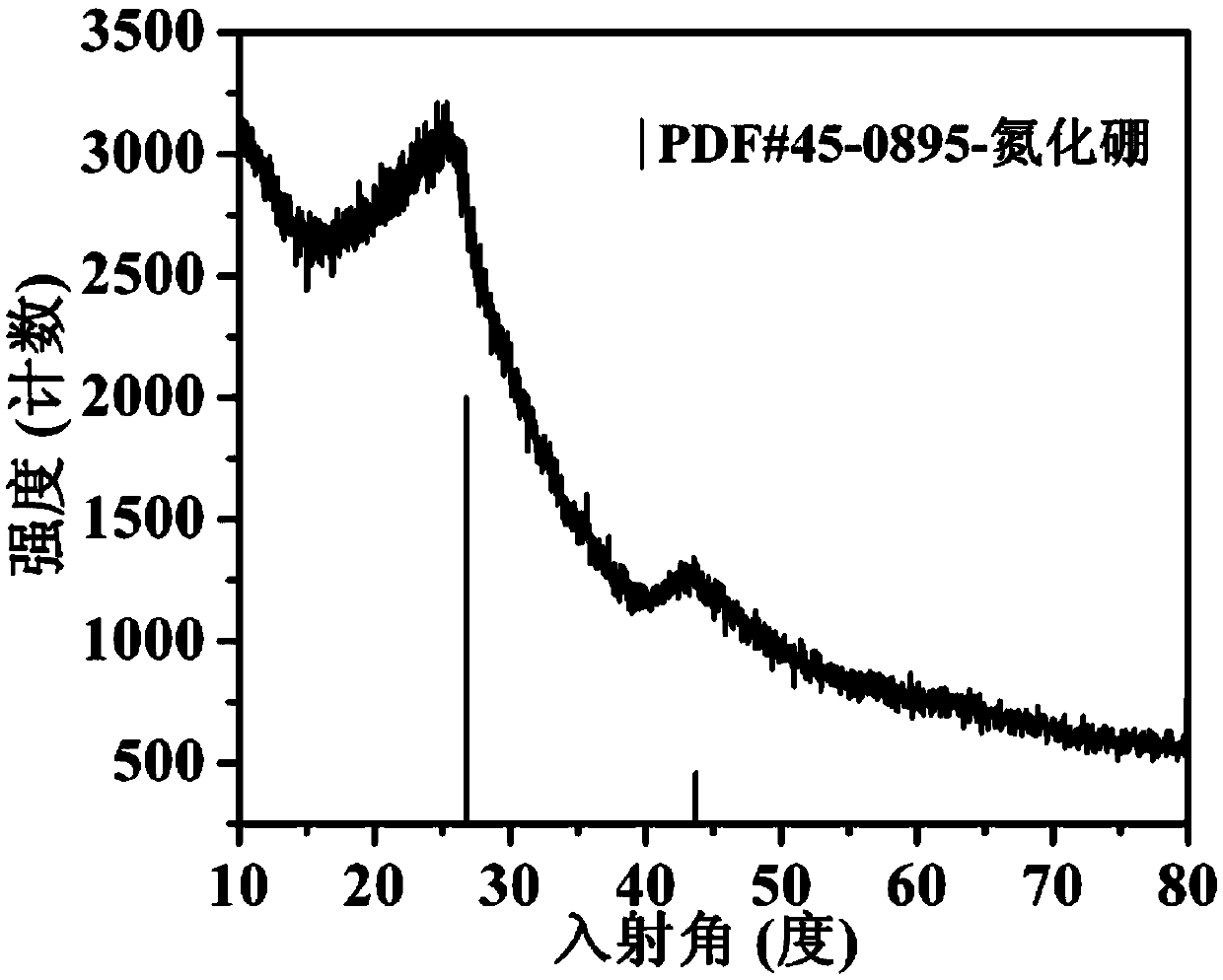

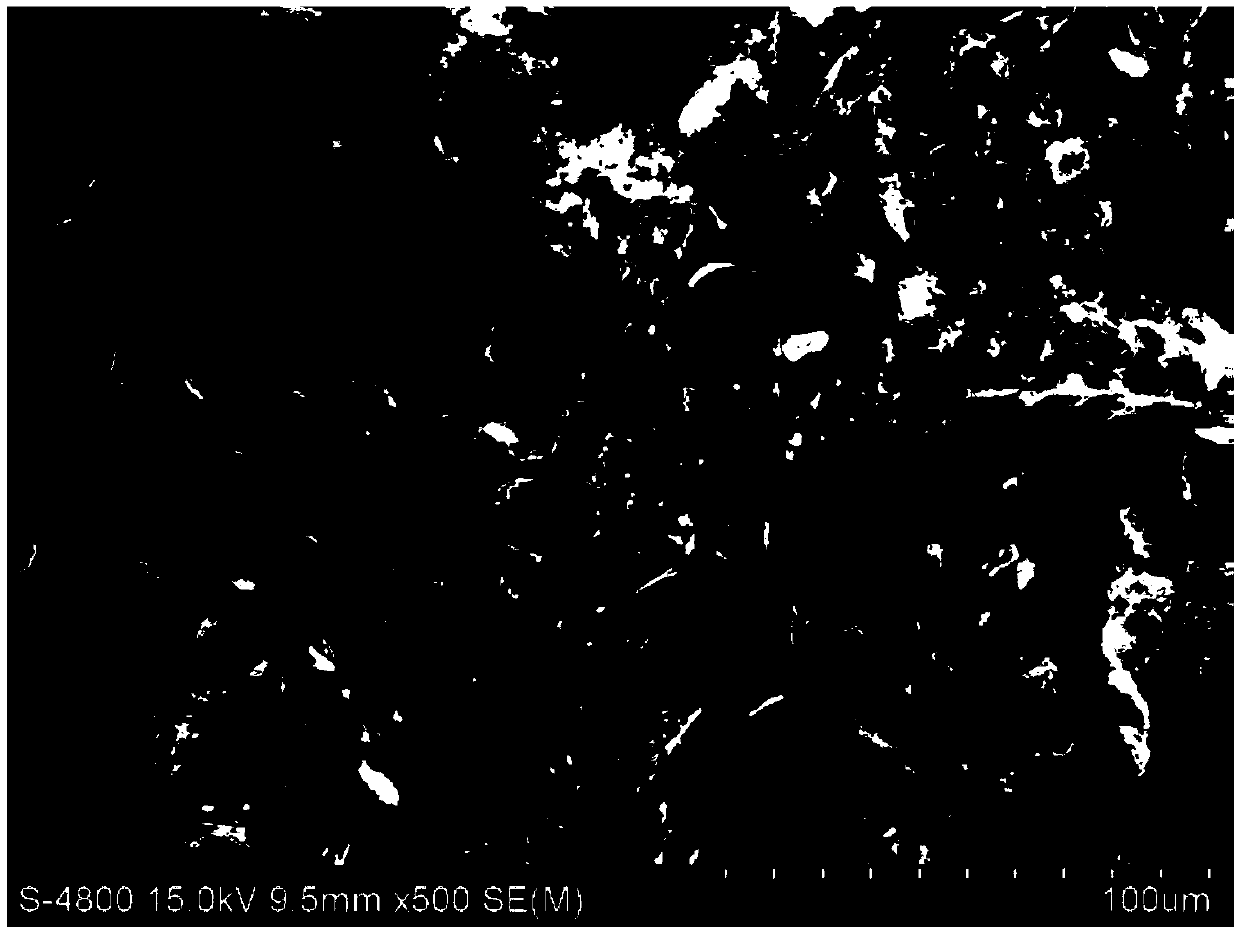

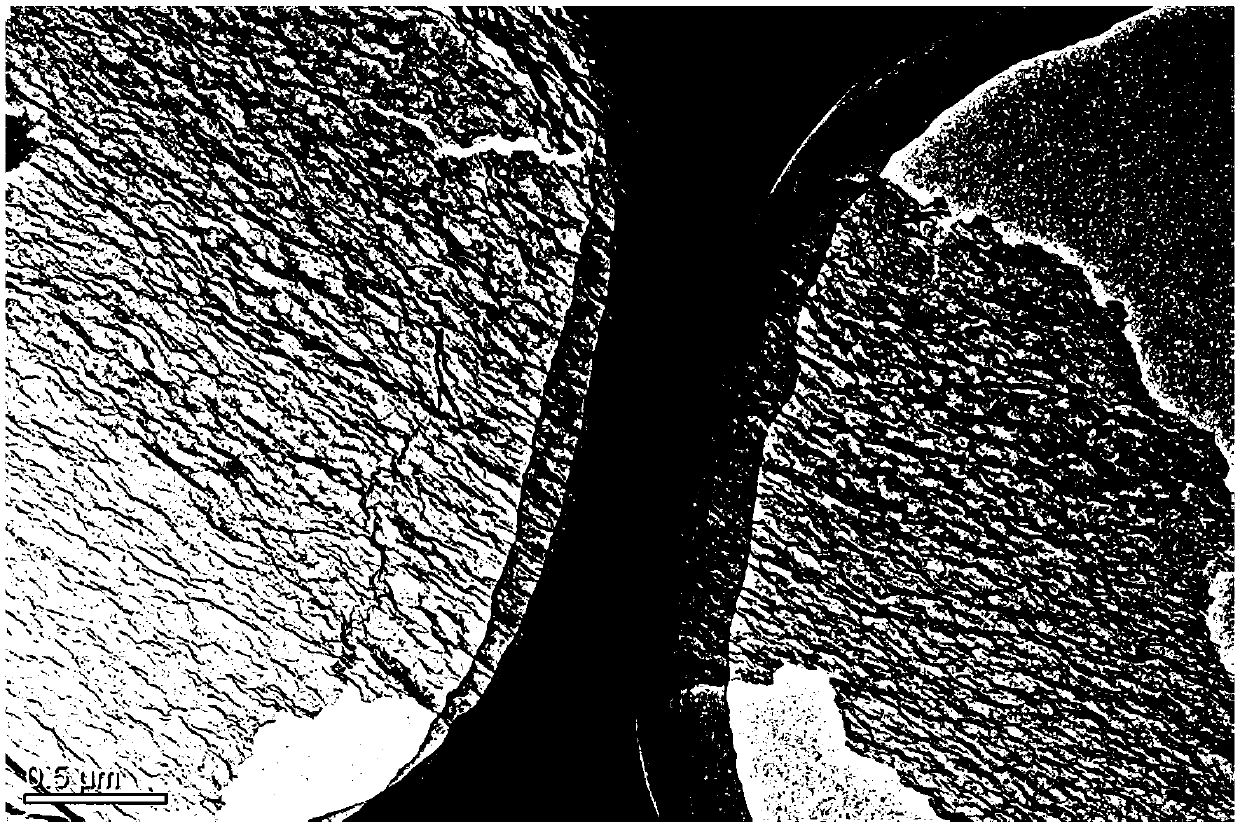

[0034] Test results: Different BCNO luminescent nanosheets were prepared by changing the volume of ethylene glycol. The BCNO luminescent nanosheets were measured by X-ray diffraction, scanning electron microscope, transmission electron microscope, infrared spectrum and emission spectrum. The test results are as follows: Figure 1-8 shown. figure 1 It is the X-ray diffraction pattern of BCNO nanosheets prepared when the ratio of boric acid and dicyandiamide is 1:2, and the amount of ethylene glycol is 20ml. The sample has two broad diffraction peaks near 26 degrees and 43 degrees. PDF card comparison (PDF#45-0895), shows that the structure of BCNO nanosheets is a staggered BN hexagonal structure. figure 2 It is the scanning electron microscope image of BCNO nanosheets prepared when boric acid: dicyandiamide = 1:2, and the amount of ethylene glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com