Multi-stage structure nanometer In2O3/graphene composite and preparation method and application thereof

A graphene composite and composite material technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the problems of high control parameter requirements and difficult control, and achieve good gas-sensing performance, short response time, and technology advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

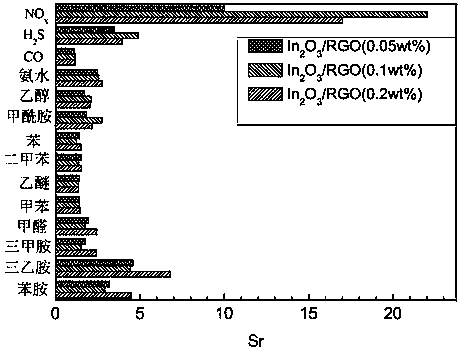

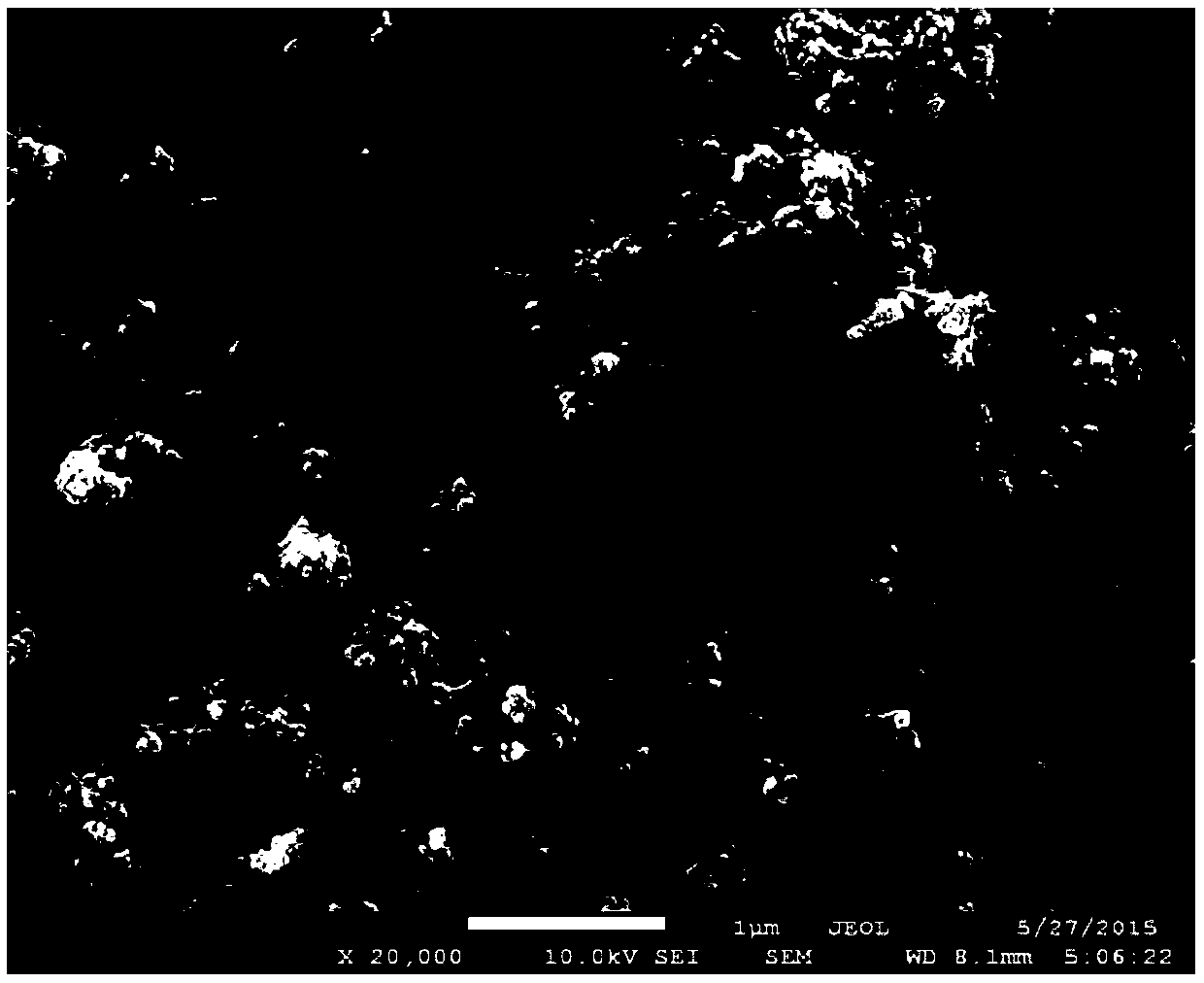

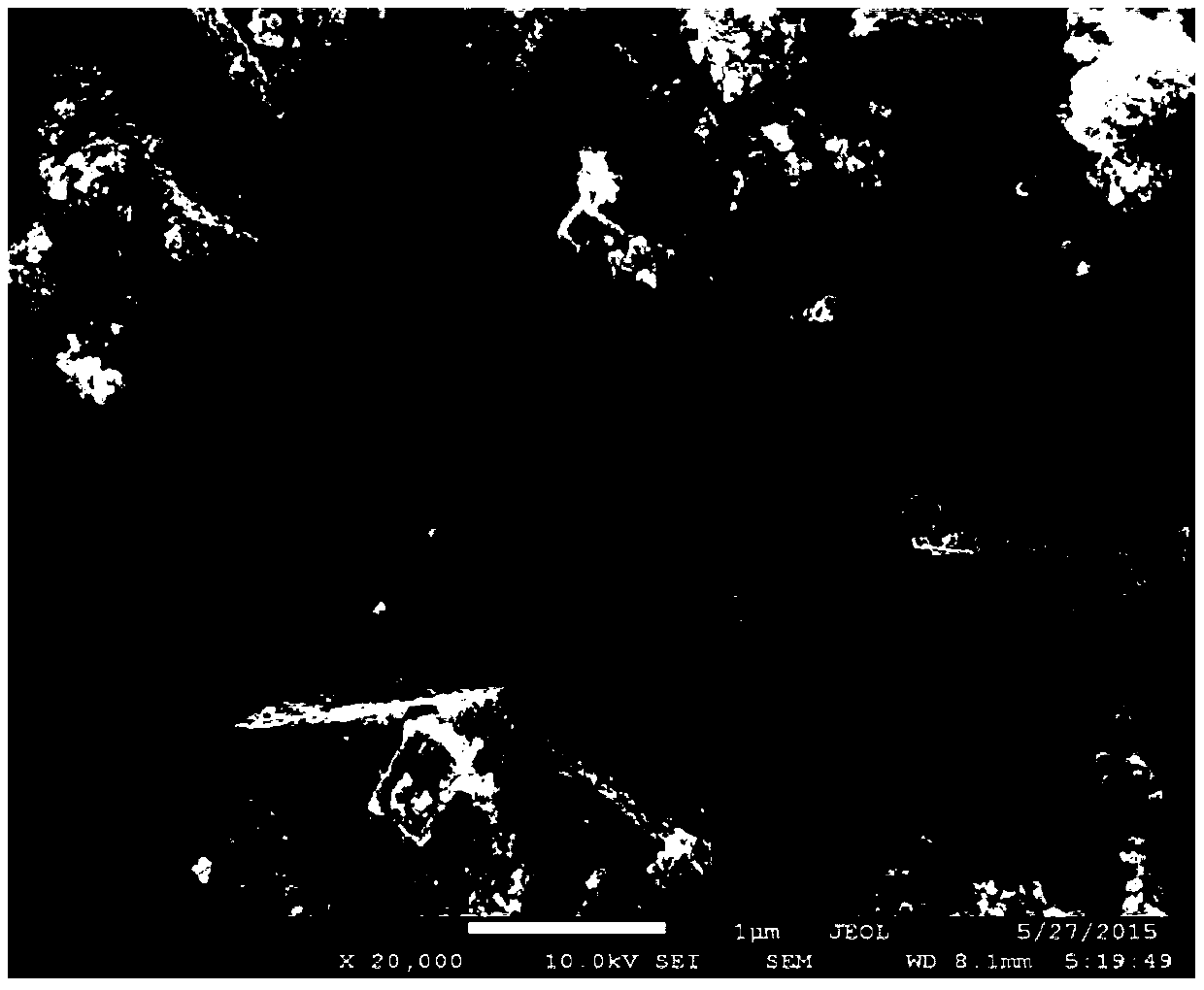

[0030] The invention provides a multi-level structure nano In 2 o 3 / Graphene composite gas sensing material, nano In 2 o 3 In situ growth on the surface of reduced graphene oxide, the final product is nano-In 2 o 3 The original nanoparticles wrapped in graphene and the regular brick-like structure In 2 o 3 / Graphene composite material, wherein the graphene content is 0.05-0.2% of the total weight. Said a kind of hierarchical structure nanometer In 2 o 3The structure of graphene composite gas-sensitive material is as accompanying drawing 1 (includes Figure 1a , Figure 1b and Figure 1c ); Its XRD spectrogram is as figure 2 shown.

[0031] Composite material preparation:

[0032] First prepare graphene oxide by the improved Hummers method, reduce graphene oxide with hydrazine hydrate, then evenly disperse an appropriate amount of reduced graphene oxide into ethylene glycol, add InCl 3 4H 2 O, magnetically stir for 1h, put the 50ml beaker containing the mixed so...

Embodiment 2

[0034] The specific preparation method of the present invention is to weigh 1.1326 parts of InCl by mass ratio 3 4H 2 O (0.002mol) was dissolved in 20 parts of ethylene glycol, stirred to fully dissolve, and a clear solution was obtained. In addition, 0.0008 parts of graphene was accurately weighed and dissolved in another 20 parts of ethylene glycol, dispersed and mixed evenly. After the graphene is fully dispersed in the ethylene glycol solution, the InCl 3 .4H 2 The clarified solution of O is slowly added to the graphene solution during the stirring process, and the stirring is continued to make it fully mixed and adsorbed. Finally, the container containing the mixed solution is placed in a polytetrafluoroethylene-lined reactor, and then placed on the outside of the container Add 0.8 parts of 15mol / L ammonia water, and put the reaction kettle into a microwave reactor for reaction. Using microwave heating and auxiliary magnetic stirring, when the temperature rises to 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com