Hydrated alumina dielectric thin film with solid electrolyte function and preparation thereof

A technology of hydrated alumina and solid electrolyte, which is applied in the direction of fixed capacitor dielectric, fixed capacitor parts, capacitor manufacturing, etc. It can solve the problems that the electrolyte occupies a large volume, has not been practically applied, and has limited application range, and achieves low raw material costs. , good electrolyte function, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

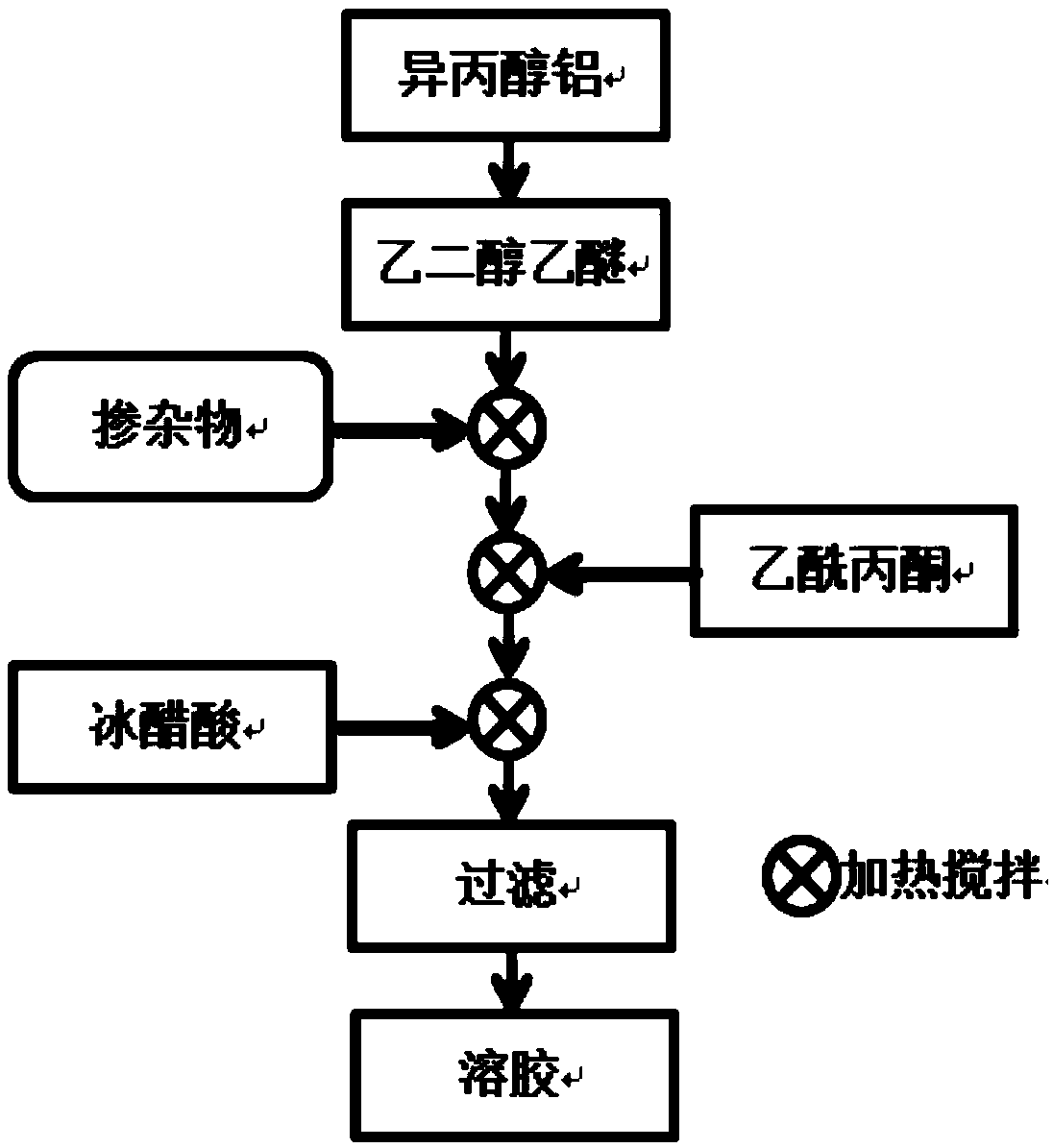

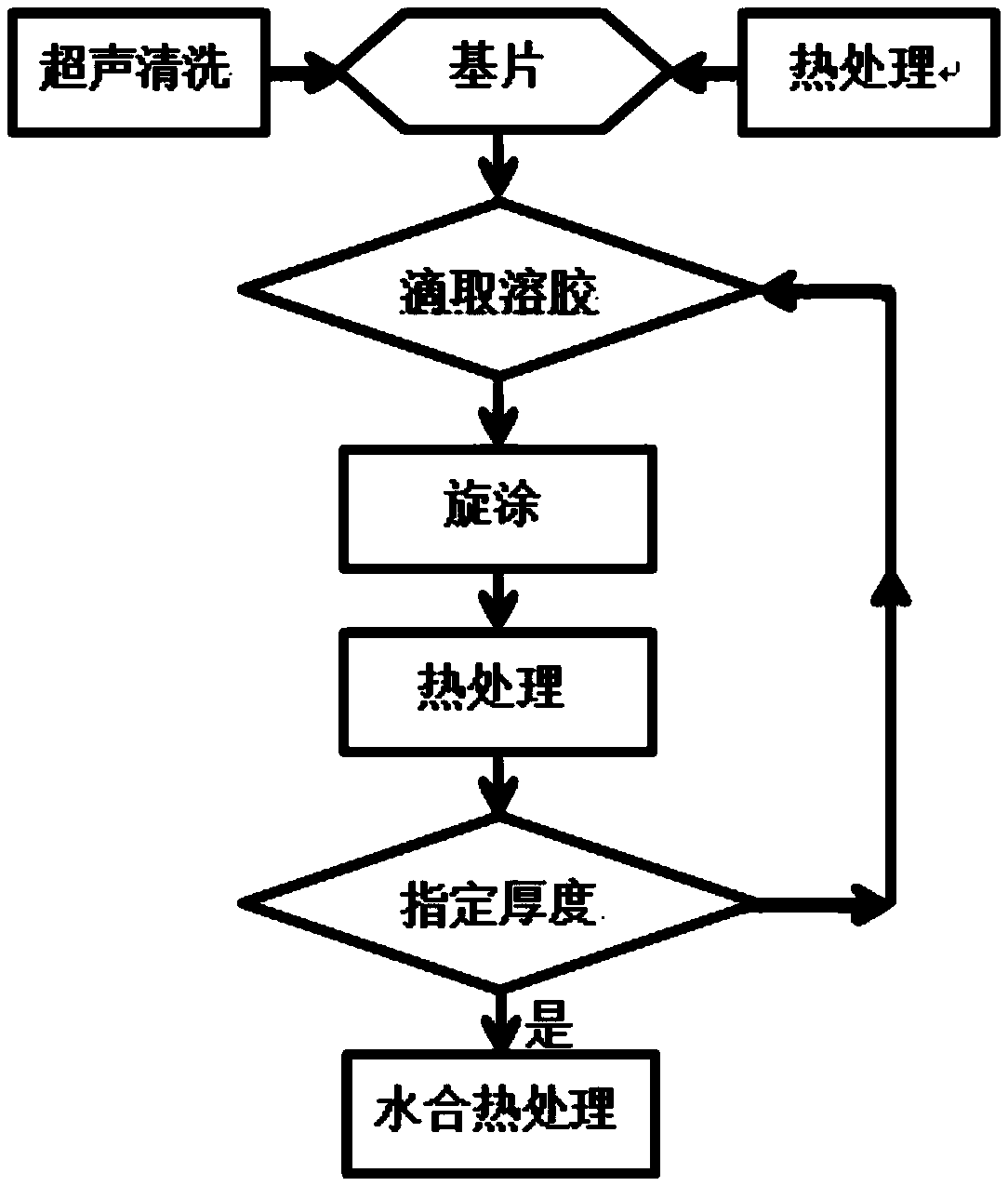

[0058] A 210nm hydrated alumina dielectric film was prepared on the surface of a Pt-coated silicon wafer by spin coating. For the preparation process see figure 1 and image 3 As shown, the details are as follows:

[0059] Grind 0.04mol of aluminum isopropoxide first, then add 100ml of ethylene glycol ether to ultrasonic for 10 minutes, stir at 70°C for 30 minutes, add 0.04mol of acetylacetone, continue stirring for 30 minutes, finally add 20ml of glacial acetic acid, and stir at 100°C for 30 minutes , gradually cooled to room temperature, and finally filtered to obtain 120ml sol precursor.

[0060] Place the Pt-coated silicon wafer sample with a clean and dry surface on a homogenizer, then drop the sol precursor on the surface of the substrate, apply the sol evenly on the surface of the substrate at a speed of 3000 rpm, and then place the sample on the Dry heat treatment in the rapid heat treatment furnace. The pre-drying process conditions are 150°C for 2 minutes, 350°C f...

Embodiment 2

[0063] The alumina hydrate film with a thickness of 210 nm prepared in Example 1 was used. On the surface of the hydrated alumina film, vacuum evaporation equipment was used to prepare an aluminum film with a diameter of 1 mm and a thickness of 150 nanometers. The ability of the hydrated alumina film to be used as a solid electrolyte was studied. The polarization curve of the anodic oxidation process of the aluminum electrode is shown in the appendix Figure 7 shown. After the aluminum electrode is anodized, its cross-sectional view is shown in the attached Figure 8 As shown, an anodic oxide film (AAO) of about 50 nm is formed at the interface between the amorphous aluminum oxide film (AmAO) and the aluminum film (Al). It can be seen that the hydrated alumina dielectric film prepared by this method has a good solid electrolyte function, and can be used as the required negative ion (OH - or O 2- ) source.

Embodiment 3

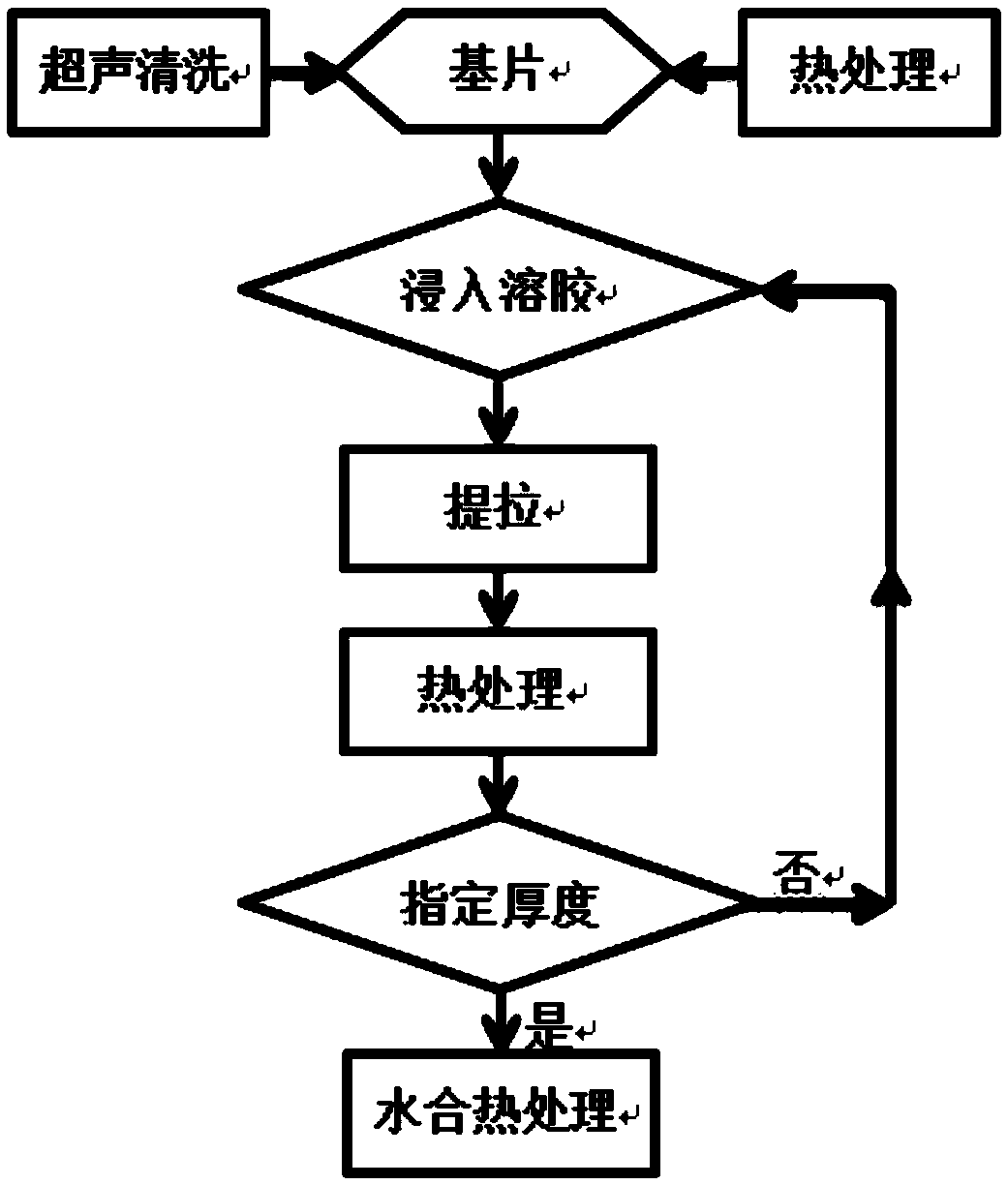

[0065] A hydrated aluminum oxide film is prepared on the surface of an aluminum sheet that has been anodized in a liquid electrolyte to form porous aluminum oxide by a pulling method. Preparation process see figure 1 and figure 2 As shown, the details are as follows:

[0066] Grind 0.04mol of aluminum isopropoxide first, then add 100ml of ethylene glycol ether to ultrasonic for 10 minutes, stir at 70°C for 30 minutes, add 0.04mol of acetylacetone, continue stirring for 30 minutes, finally add 20ml of glacial acetic acid, and stir at 100°C for 30 minutes , gradually cooled to room temperature, and finally filtered to obtain 120ml sol precursor.

[0067] The sample with a clean and dry surface is immersed in the sol precursor for 20 seconds, then the sample is pulled out of the sol, and the sample is placed in a rapid heat treatment furnace for drying heat treatment. The pre-drying process conditions are 150°C for 2 minutes, 350°C Treatment for 1 minute, 450°C for 1 minute, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com