Taxol composition for injection and preparation method thereof

A technology for paclitaxel and injection, applied in the field of paclitaxel composition for injection and preparation thereof, can solve the problems of drug safety risk, inability to withstand high pressure sterilization, unfavorable industrialization, etc., and achieves reduction of drug risk and low lipid content. , the effect of high drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] [Preparation of paclitaxel composition for injection]

[0076] The invention provides a preparation method of a paclitaxel composition for injection, which is characterized in that, when preparing an oil phase, paclitaxel, an emulsifier and anhydrous ethanol are mixed and stirred until clear, then an injection oil and a stabilizer are added, and further stirring When it is clear, the ethanol is evaporated in vacuo to obtain an oil phase.

[0077] Specifically, when preparing the paclitaxel composition for injection of the present invention, the amount of anhydrous ethanol used is far lower than the prescription amount recorded in the prior art, and it is finally removed under vacuum conditions. Thereby, the risk of ethanol irritation can be reduced, and the drug safety is better compared with the case of using other organic solvents such as acetone.

[0078] In the following, the case where the paclitaxel composition for injection according to the present invention is ...

Embodiment 1

[0100] Example 1 (freeze-dried microemulsion of paclitaxel for injection)

[0101] prescription

[0102]

[0103] Preparation:

[0104] (1) Oil phase: at 40-70°C, mix paclitaxel, egg yolk lecithin, soybean lecithin and absolute ethanol and stir until clarification, then add vitamin E and oleic acid, further stir until clarification, and evaporate ethanol in vacuum , the oil phase is obtained;

[0105] (2) Water phase: add arginine and sucrose to water for injection, stir until completely dissolved, and filter with 0.22 μm microporous membrane to obtain water phase;

[0106] (3) Colostrum: First preheat the water phase and the oil phase to 50-70°C, then use a high-speed disperser to slowly add the water phase to the oil phase under shear stirring at 5000-20,000 rpm, and after the addition is complete , continue shearing and stirring at 10000rpm for 30 minutes to obtain colostrum;

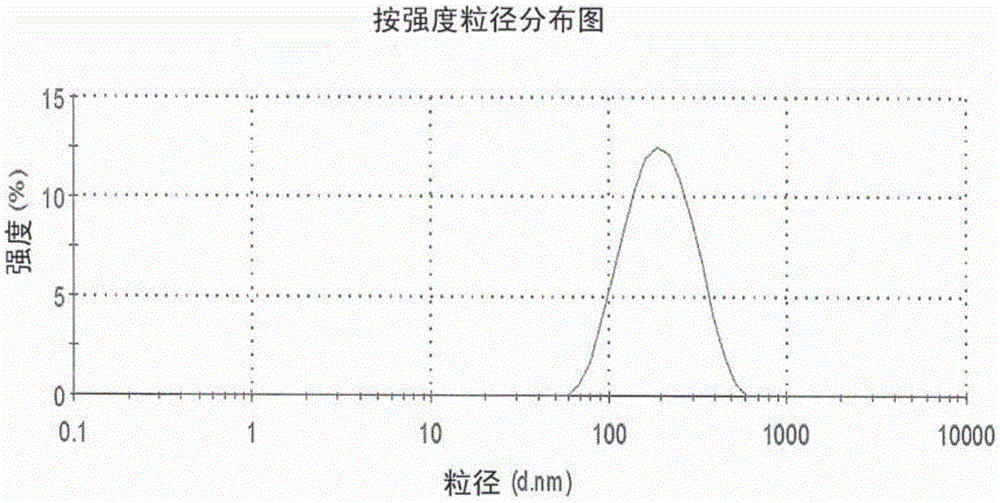

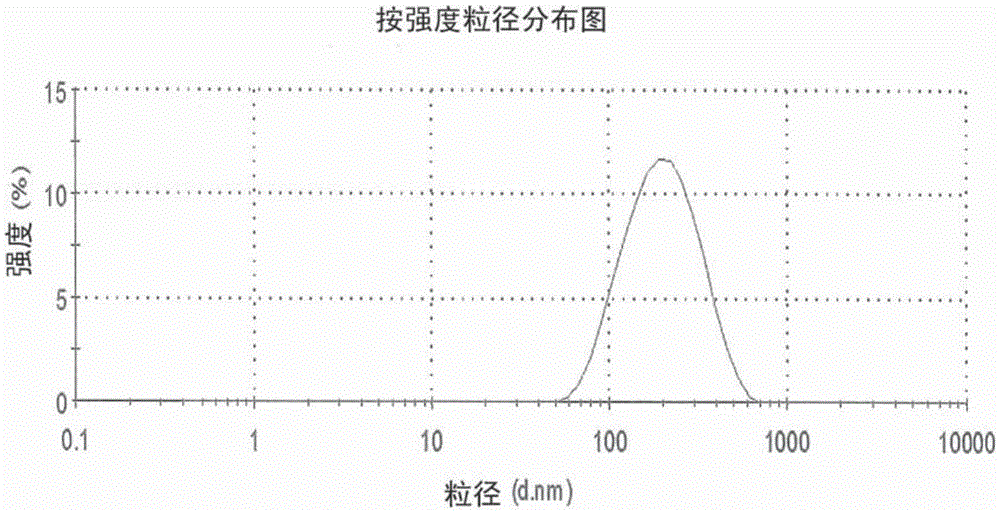

[0107] (4) Final milk: Cool the colostrum to room temperature, then transfer it to a high-pr...

Embodiment 2

[0132] Example 2 (paclitaxel microemulsion for injection)

[0133] prescription

[0134]

[0135] Preparation:

[0136] (1) Oil phase: at 40-70°C, mix paclitaxel, egg yolk lecithin and absolute ethanol and stir until clear, then add vitamin E, dl-α-tocopherol and oleic acid, and further stir until clear, The ethanol was evaporated in a vacuum to obtain an oil phase;

[0137] (2) Water phase: add lysine and sucrose to water for injection, stir until completely dissolved, and filter with a 0.22 μm microporous membrane to obtain the water phase;

[0138] (3) Colostrum: first preheat the water phase and the oil phase to 50-70°C, then use a high-speed disperser to slowly add the water phase to the oil phase under shear stirring at 5000-20,000 rpm, and after complete addition, Continue stirring at 8000rpm for 20 minutes to obtain colostrum;

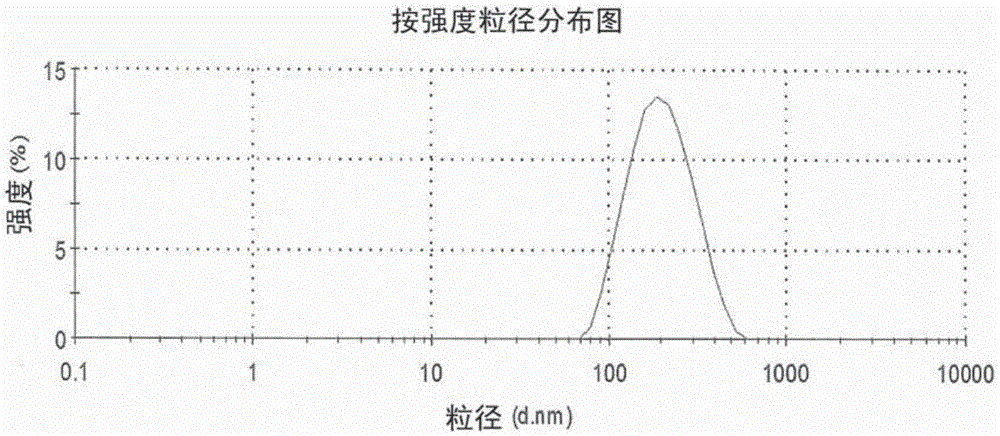

[0139] (4) Final milk: Cool the colostrum to room temperature, then transfer the colostrum to a high-pressure homogenizer, and homogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com