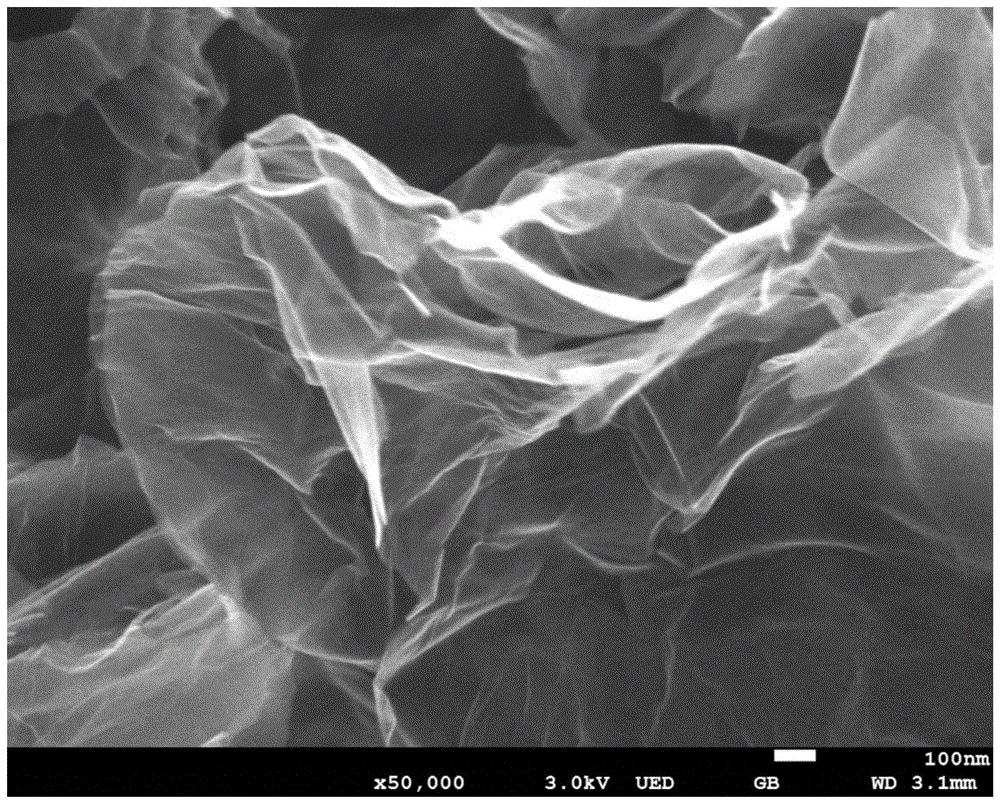

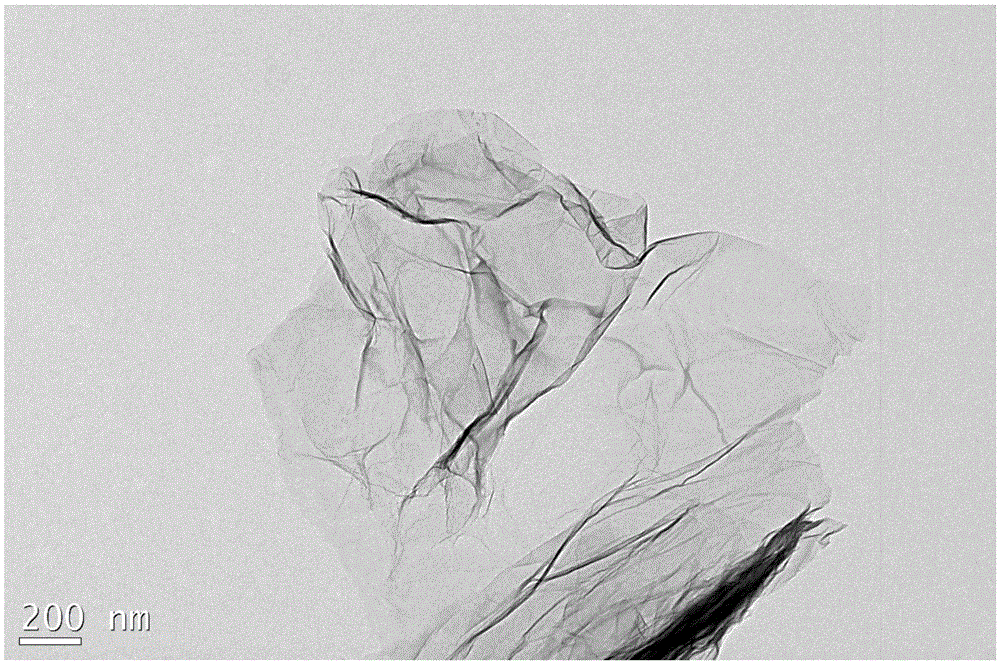

Method for preparing single-layer graphene

A single-layer graphene and graphite technology, applied in the field of preparation of single-layer graphene, can solve the problems of high time cost in the preparation process, unsuitable for industrial production, unfriendly environment, etc., to save time cost and production cost, and widely industrial applications Foreground, the effect of enhancing the oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] (1) Add mineral acid, sodium benzenesulfonate, and peroxybenzoic acid to graphite, and add KMnO after reacting for 1.5 hours at a reaction temperature of 20°C. 4 , stirred evenly and reacted for 4 hours at a reaction temperature of 62°C to obtain a brownish-yellow solution; wherein, the mass ratio of graphite, sodium benzenesulfonate, peroxybenzoic acid, and inorganic acid was 1:3:9:27; KMnO 4 The mass ratio to graphite is 8:1; among them, the inorganic acid is concentrated H with a mass fraction of 90% 2 SO 4 ;

[0031] (2) Add water to the brownish-yellow solution for dilution, then add H 2 o 2 until the solution is bright yellow, then filter, add the filter cake to ethanol and stir evenly, after filtering, wash the filter cake with hydrochloric acid with a mass fraction of 5%, and then wash it to neutrality to obtain graphite oxide;

[0032] (3) Add ethylenediamine to the graphite oxide, so that the graphite oxide is evenly dispersed in the ethylenediamine, then ...

Embodiment 3

[0034] (1) Add mineral acid, sodium benzenesulfonate, and peroxybenzoic acid to graphite, and add KMnO after reacting for 2.5 hours at a reaction temperature of 30°C. 4 , stirred evenly and reacted for 3 hours at a reaction temperature of 65°C to obtain a brownish-yellow solution; wherein, the mass ratio of graphite, sodium benzenesulfonate, peroxybenzoic acid, and inorganic acid was 1:5:6:28; KMnO 4 The mass ratio to graphite is 10:1; wherein, the inorganic acid is concentrated nitric acid with a mass fraction of 80%;

[0035] (2) Add water to the brownish-yellow solution for dilution, then add H 2 o 2 until the solution is bright yellow, then filter, add the filter cake to ethanol and stir evenly, after filtering, wash the filter cake with hydrochloric acid with a mass fraction of 5%, and then wash it to neutrality to obtain graphite oxide;

[0036] (3) Add ethylenediamine to the graphite oxide, so that the graphite oxide is evenly dispersed in the ethylenediamine, then re...

Embodiment 4

[0038] (1) Add mineral acid, sodium benzenesulfonate, and peroxybenzoic acid to graphite, and add KMnO after reacting for 3 hours at a reaction temperature of 25°C. 4 , after stirring evenly, react at a reaction temperature of 60°C for 5 hours to obtain a brown-yellow solution; wherein, the mass ratio of graphite, sodium benzenesulfonate, peroxybenzoic acid, and inorganic acid is 1:4:8:30; KMnO 4The mass ratio to graphite is 9:1; among them, the inorganic acid is concentrated H with a mass fraction of 90% 2 SO 4 ;

[0039] (2) Add water to the brownish-yellow solution for dilution, then add H 2 o 2 until the solution is bright yellow, then filter, add the filter cake to ethanol and stir evenly, after filtering, wash the filter cake with hydrochloric acid with a mass fraction of 5%, and then wash it to neutrality to obtain graphite oxide;

[0040] (3) Add ethylenediamine to the graphite oxide, so that the graphite oxide is uniformly dispersed in the ethylenediamine, then re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com