Urea-based lubricating grease composition with excellent antifriction property and preparation method therefor

A technology of grease composition and urea-based grease, which is applied in the field of grease, can solve problems such as complex preparation process and complex process, and achieve the effect of improving wear reduction ability and anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

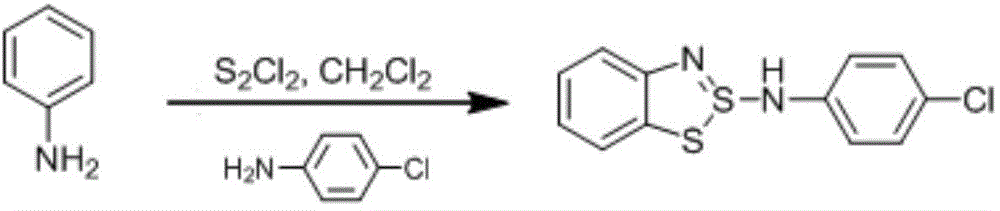

[0052] Among the present invention, the preparation method of the compound of structure shown in formula (I) preferably comprises:

[0053] (a) react aniline, sulfur chloride and 4-chloroaniline to generate intermediate M shown in formula (II),

[0054]

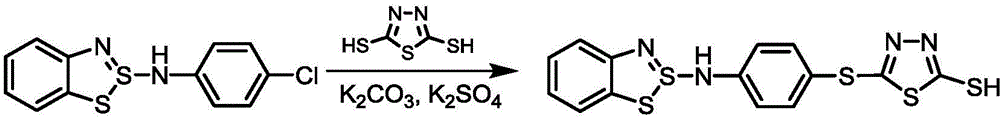

[0055] (b) carrying out nucleophilic substitution reaction between the intermediate M obtained in step (a) and dimercapto-1,3,4-thiadiazole under alkaline conditions to generate the multi-effect additive shown in formula (I),

[0056]

[0057] In step (a) of the present invention, the specific mode of reacting aniline, sulfur chloride and 4-chloroaniline preferably includes:

[0058] (i) fully reacting aniline and sulfur chloride at -20-0°C in the first solvent under an inert atmosphere;

[0059] (ii) Add 4-chloroaniline into the reaction system of step (i), and react at 15-30° C. for 1-3 h.

[0060] In the present invention, the inert atmosphere can be a conventional inert atmosphere in the field, for example, it can...

Embodiment

[0103] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0104] In the following examples and comparative examples:

[0105] The method for monitoring the complete reaction: thin-layer chromatography (TLC) fluorescence color method.

[0106] Total yield = molar amount of final product / molar amount of aniline × 100%

[0107] The physical and chemical analysis method of the product: the element content was determined by inductively coupled plasma ion emission spectrometry.

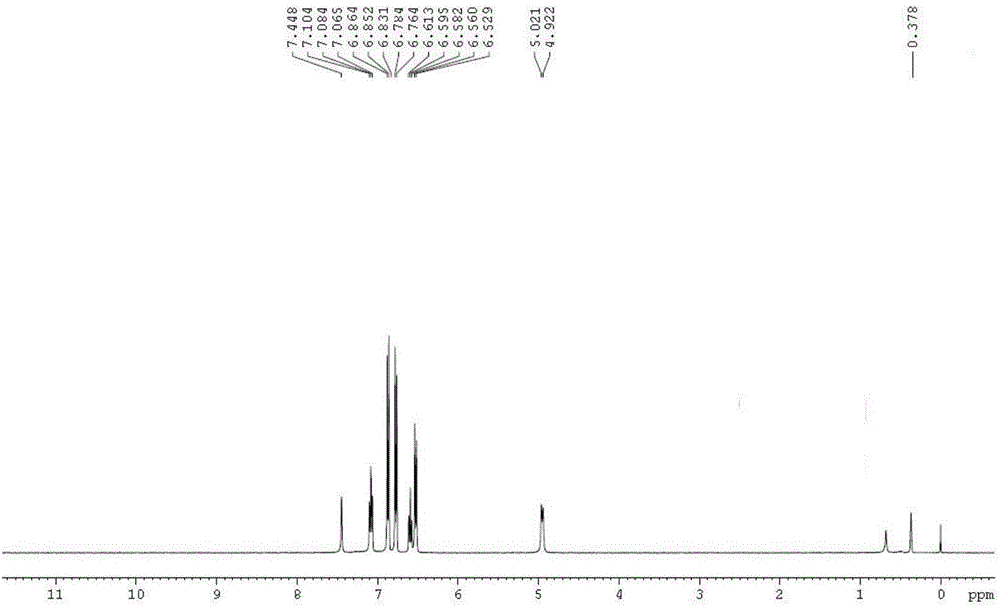

[0108] Structural characterization method: NMR method ( 1 H spectrum, 13 C carbon spectrum), high-resolution mass spectrometry.

[0109] Test methods for each index: dropping point: GB / T3498; working penetration: GB / T269; extended working penetration: GB2360-1980; initial oxidation temperature: PDSC; steel mesh oil separation: SH / T0324; corrosion resistance: GB / T5018; water loss: SH / T0109; four-ball machine test PB, PD: SH / T0202; copp...

preparation example

[0111] Fill a 500ml flask with an electromagnetic stirrer (stirring speed is 300rpm) with nitrogen protection, add 150ml of dichloromethane, then add 0.2mol of sulfur chloride, fully cool in an ice-water bath, add 0.2mol of aniline . Remove the ice-water bath after monitoring until the reaction is complete, and place it at room temperature of 25°C. After the reaction system gradually rises to 25°C, add 4-chloroaniline in 3 times for reaction. The amount added each time is the same, and 4-chloroaniline is added in total 0.15mol. After the reaction was continued for 2 hours, 30ml of saturated brine was added to quench the reaction, and then the reaction system was transferred to a separatory funnel, washed with 50ml of distilled water and 50ml of saturated brine, and dried by adding 10g of anhydrous sodium sulfate at 25°C for 20min. The filtered filtrate was evaporated to remove the solvent at 40° C. and 0.05 MPa to obtain intermediate M1.

[0112] Fill a 500ml flask with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com