Modified chinlon fiber, preparation method and application

A nylon fiber and modification technology, applied in the field of nylon modification preparation, can solve problems such as graphene doping, and achieve the effects of avoiding cold, improving dispersibility, low temperature far-infrared and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

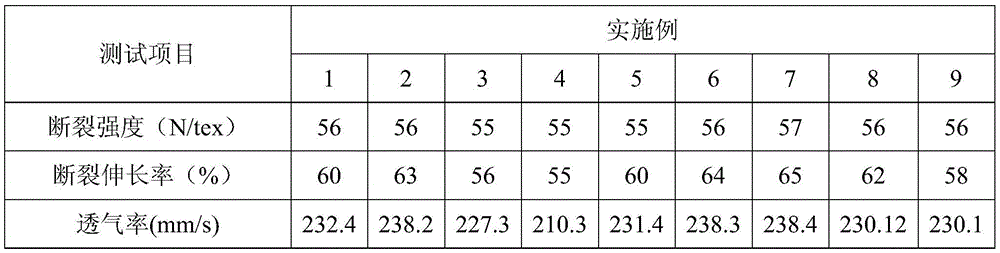

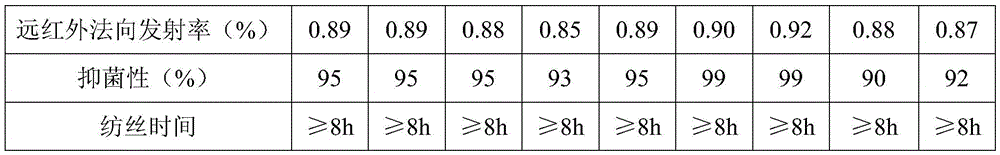

Examples

preparation example 1

[0116] Graphene preparation example 1 (redox graphene)

[0117] Adopt publication number to be the method for embodiment 1 in the patent of CN105217621A, specifically:

[0118] (A) React 2g of graphite powder with 3g of potassium dithionate, 3g of phosphorus pentoxide and 12mL of concentrated sulfuric acid in a reactor, and stir for 4 hours in a water bath at 80°C until a dark blue solution is formed. Cool, Obtain pre-oxidized graphite after suction filtration and drying;

[0119] (B) Get 2g of graphite oxide prepared by step (A) in a three-necked flask, and gradually add 25g of potassium permanganate with 150mL of concentrated sulfuric acid solution under the condition of an ice-water bath, and stir for 2 hours;

[0120] (C) Transfer the three-necked flask of the above step (B) to an oil bath, heat up to 35°C, stir for 2 hours, continue stirring and add a mixed solution of 30wt% hydrogen peroxide and deionized water in a volume ratio of 1:15 Suction filtration, washing once...

preparation example 2

[0123] Graphene preparation example 2 (biomass graphene)

[0124] Adopt publication number to be the method for embodiment 10 in the patent of CN104724696A, specifically:

[0125] Collect the straw, clean it, cut it into small pieces, soak it in the ethanol solution, stir at a constant speed of 100r / min for 5 hours; then transfer the solution to a high-speed centrifuge, set the speed at 3000r / min, and centrifuge for 20 minutes , after the end, remove the broken sample layer. Under normal temperature and pressure, put the crushed sample into a cell culture dish with a diameter of 15cm, place it at the air inlet, adjust the flow parameters, set the wind speed to 6m / s, the air volume to 1400m3 / h, and keep the ventilation state for 12 hours; The temperature of the furnace was raised to 1300°C, and an inert gas protection was introduced, and kept for 30 minutes; the dried and broken samples were placed in a tube furnace, heated for 5 hours, and after cooling to room temperature, gra...

preparation example 3

[0126] Graphene preparation example 3 (biomass graphene from special sources)

[0127] The preparation method of conventional cellulose is specifically:

[0128] (1) After the wheat straw is pulverized and pretreated, use the organic acid solution whose total acid concentration is 80wt% formic acid and acetic acid to cook the treated wheat straw, the quality of acetic acid and formic acid in the organic acid solution of the present embodiment Ratio is 1:12, and before adding raw materials, add hydrogen peroxide (H2O2) that accounts for 1wt% of wheat straw raw material as catalyst, control reaction temperature 120 ℃, react 30min, solid-liquid mass ratio is 1:10, and will get The reaction liquid is carried out solid-liquid separation for the first time;

[0129] (2) the solid that solid-liquid separation obtains for the first time is added the organic acid liquid that total acid concentration is 75wt% formic acid and acetic acid to carry out acid washing, wherein the organic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com