Preparation method and application of Fe3O4@SiO2@Zr-MOF

A reaction kettle and mixed solution technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve rare problems, achieve good stability, good separation effect, and easy operation line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Fe 3 O 4 SiO 2 The preparation method of magnetic particles is as follows: ①Add 5.4g FeCl 3 ·6H 2 O, 60ml of ethylene glycol was placed in a 100ml beaker, ultrasonically stirred for 30 minutes, until a transparent solution was formed, then 3.28 sodium acetate was added, ultrasonically mixed for 30 minutes, when completely dissolved, transferred to a stainless steel kettle lined with PTFE, 200 Heated at ℃ for 10h, after cooling, collected the precipitate by magnetic separation, washed with water and ethanol under ultrasound, and dried under vacuum at 60℃ for 12h. Get Fe 3 O 4 Nano microspheres.

[0024] ②Take the new Fe 3 O 4 Add 1.0g of nanospheres to a 250ml beaker, add 200ml of 0.1mol / L hydrochloric acid, sonicate for 5min, and wash with ultrapure water 3 times. After magnetic collection, add 320ml ethanol, 80ml ultrapure water and 5ml ammonia (20% -28% mass fraction), 1ml tetraethyl orthosilicate (TEOS), and then ultrasonically shake for 10 minutes. Then transfer to a ...

Embodiment 1

[0026] Dissolve zirconium chloride (53mg) and terephthalic acid (34mg) in DMF (18mL), dissolve ultrasonically at room temperature, and then add Fe 3 O 4 SiO 2 (53mg) was then sealed in a 25mL hydrothermal reaction kettle, and then the reaction mixture was heated to 120°C, maintained at this temperature for 24h, and then cooled to room temperature. After the post-treatment, the target product was recirculated 3 times.

[0027] Fe in this example 3 O 4 SiO 2 The structure characterization and adsorption performance of Zr-MOF:

[0028] (1) Fe 3 O 4 SiO 2 Structural characterization of Zr-MOF

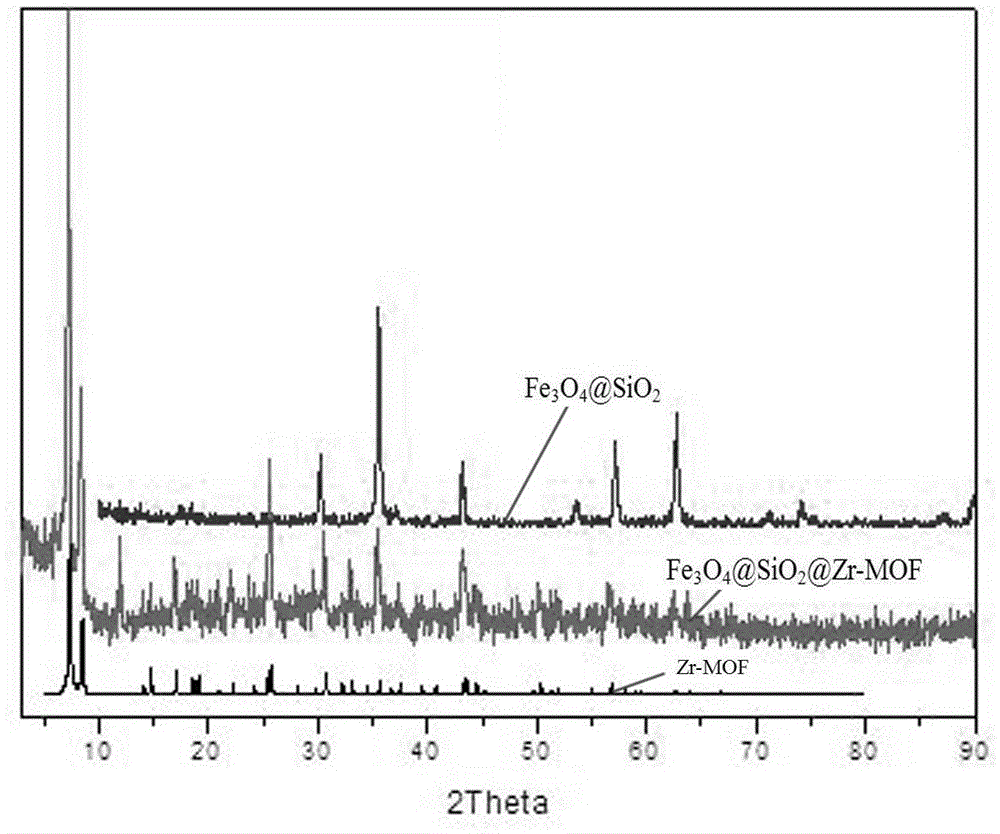

[0029] The D8Advance X-ray diffractometer (XRD) was used to characterize the prepared Fe3O4SiO2Zr-MOF hybrid particles. The sample is analyzed for phase and crystal form. Sample test conditions: voltage 35kV, current 20mA, 2θ scanning range is 3°~90°. And with Fe 3 O 4 The standard card is compared with the standard peak value of Zr-MOF, such as figure 1 .

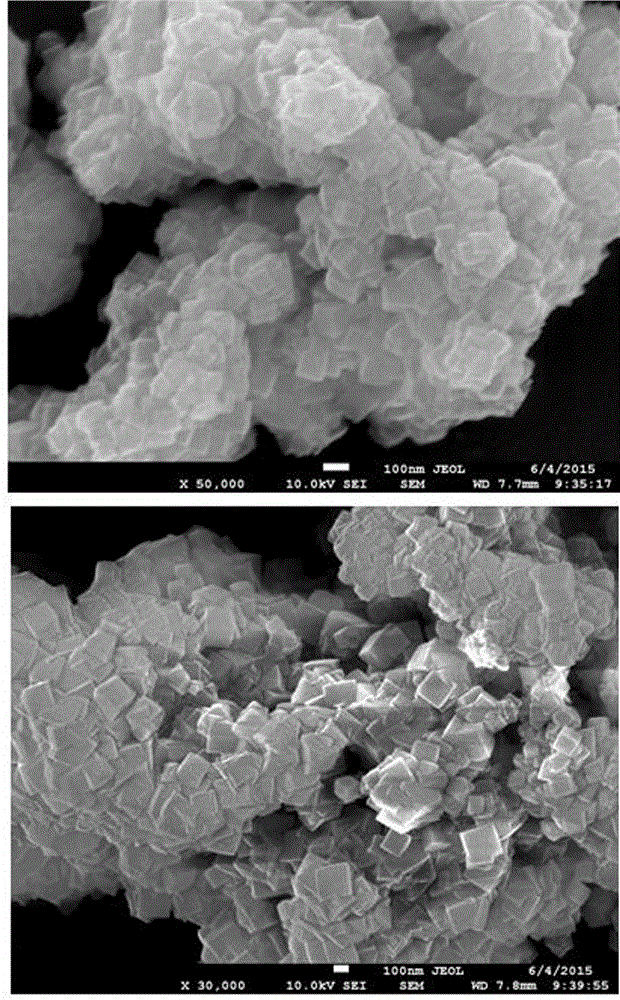

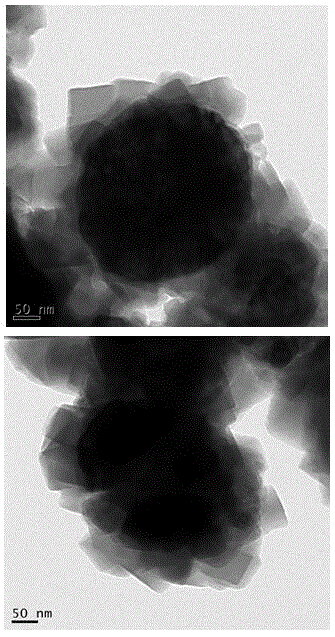

[0030] The morphology and size of magn...

Embodiment 2

[0038] Dissolve 25.2mg of zirconium chloride and 36mg of terephthalic acid in DMF (18mL), dissolve it ultrasonically at room temperature, and then add 36mg of Fe 3 O 4 SiO 2 Then it was sealed in a 25mL hydrothermal reactor, and the reaction mixture was heated to 135°C, maintained at this temperature for 24 hours, and then cooled to room temperature. After the post-treatment, the target product can be obtained by circulating 4 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com