Preparation method of anion exchange chromatography stationary phase

A technology of exchange chromatography and anion, applied in the field of preparation of anion exchange chromatography stationary phase, can solve the problems of acid and alkali resistance, difficult chemical modification, poor chemical stability, etc., and achieves low cost, wide pH tolerance range, and reactivity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing an anion-exchange chromatography stationary phase, including the preparation of monodisperse seed microspheres, the preparation of highly cross-linked glycidyl methacrylate-divinylbenzene copolymer microspheres and the preparation of anion-exchange chromatography stationary phase . The specific technical scheme is as follows:

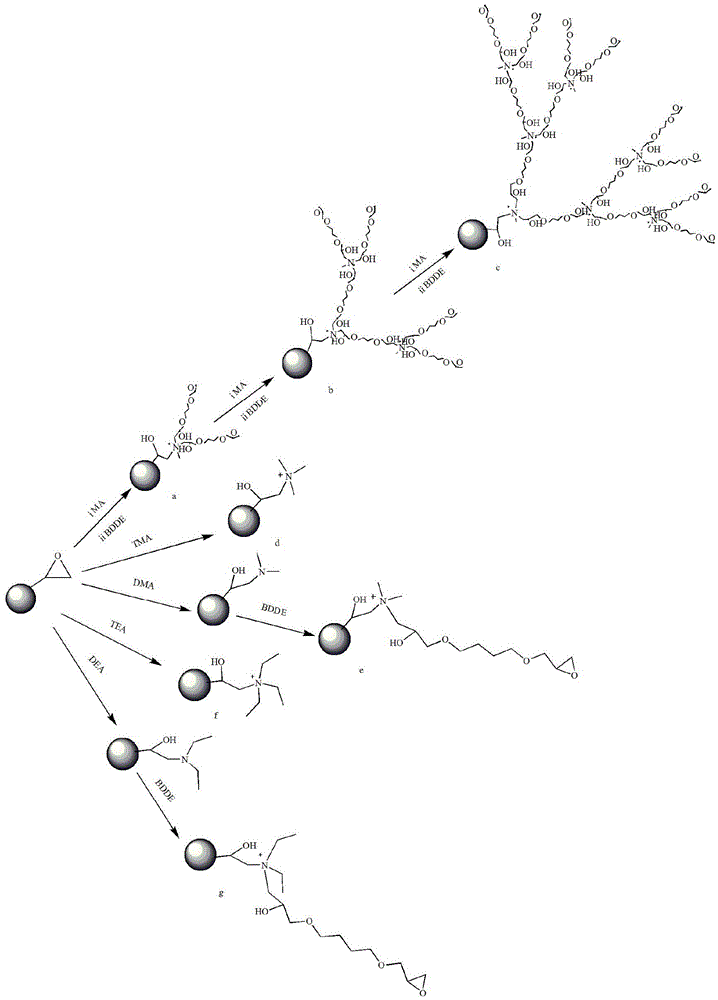

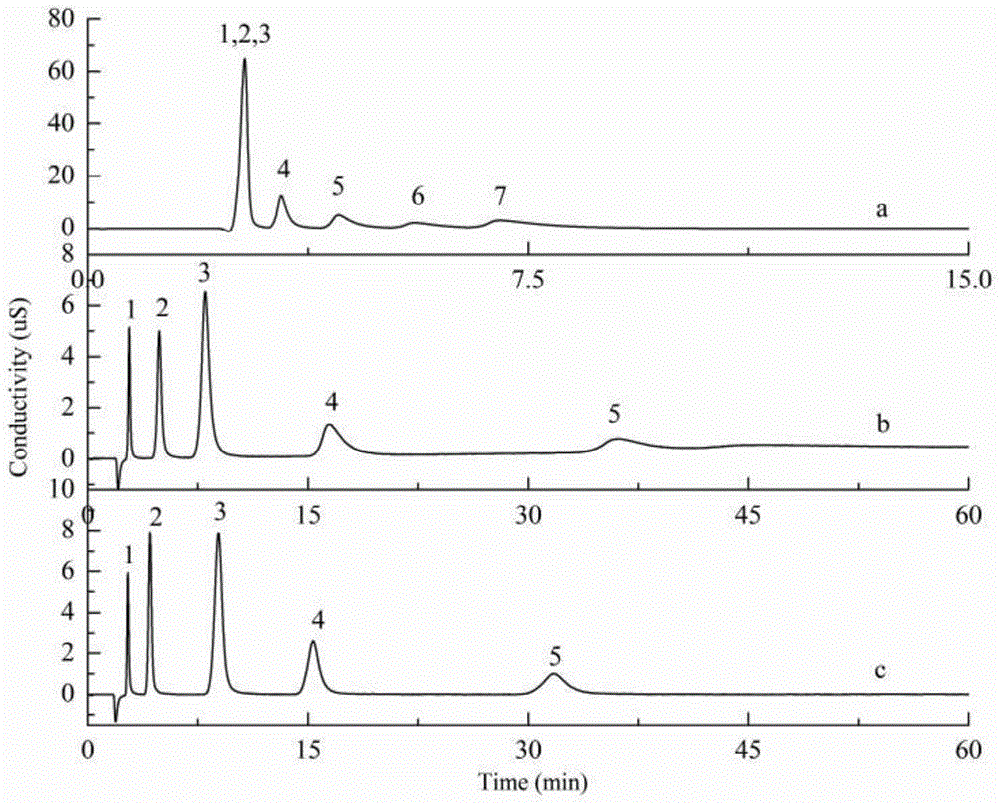

[0023] The invention adopts a dispersion polymerization method to prepare monodisperse linear polystyrene seed microspheres; adopts a two-step seed swelling method to prepare highly cross-linked glycidyl methacrylate-divinylbenzene copolymer microspheres; Amine, trimethylamine, diethylamine, triethylamine and 1,4-butanediol diglycidyl ether were used as raw materials to modify highly cross-linked glycidyl methacrylate-divinylbenzene copolymer microspheres. Introduce quaternary ammonium functional groups on the surface of glycidyl acrylate-divinylbenzene copolymer microspheres; use the homogenate meth...

Embodiment 1

[0034]Embodiment 1: The preparation steps of highly cross-linked glycidyl methacrylate-divinylbenzene copolymerized microspheres weakly acidic cationic stationary phase are:

[0035] 1. First prepare monodisperse linear polystyrene seed microspheres with a particle size of about 1.8 μm by dispersion polymerization. The reaction medium is a mixed solution of ethanol and water, and the amount of ethanol is 75% (v / v); the amount of monomer styrene is the reaction 5% (m / m) of the medium consumption, the stabilizer polyvinylpyrrolidone consumption is 0.5% (m / m) of the reaction medium consumption, and the initiator azobisisobutyronitrile consumption is 1% (m / m) of the monomer consumption ), the reaction temperature is 40°C, the stirring speed is 100r / min, and the reaction time is 12h;

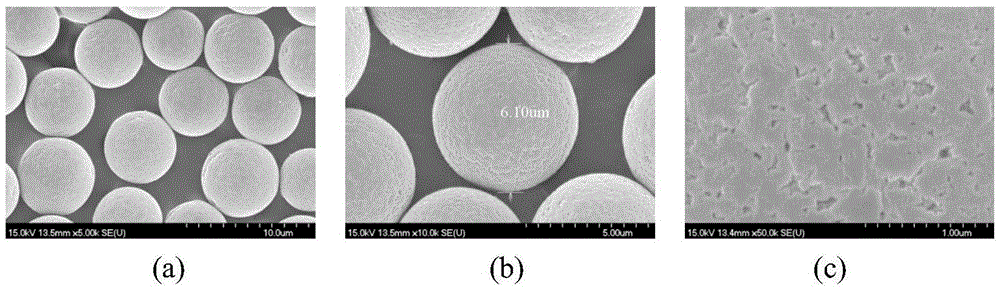

[0036] 2. Monodisperse highly cross-linked glycidyl methacrylate-divinylbenzene copolymer microspheres with a cross-linking degree of 75% were prepared by two-step seed swelling method. Seed microsp...

Embodiment 2

[0040] Embodiment 2: with reference to the method and steps of embodiment 1

[0041] 1. Synthesize 1.8 μm monodisperse polystyrene seed microspheres with a particle size of 1.8 μm earlier by dispersion polymerization, the reaction medium is a mixed solution of ethanol and water, and the amount of ethanol is 100% (v / v); the concentration of monomer styrene is the total amount 30% (m / m), the stabilizing agent polyvinylpyrrolidone consumption is 4% (m / v) of reaction medium, and initiator azobisisobutyronitrile consumption is 5% (m / m) of monomer consumption, reaction temperature 85°C, the stirring speed is 400r / min, and the reaction time is 16 hours;

[0042] 2. Monodisperse highly cross-linked glycidyl methacrylate-divinylbenzene copolymer microspheres with a cross-linking degree of 40% were prepared by two-step seed swelling method. Seed microsphere 0.6g, the consumption of monomer glycidyl methacrylate is 10% (m / m) of total organic phase consumption, and crosslinking agent div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com