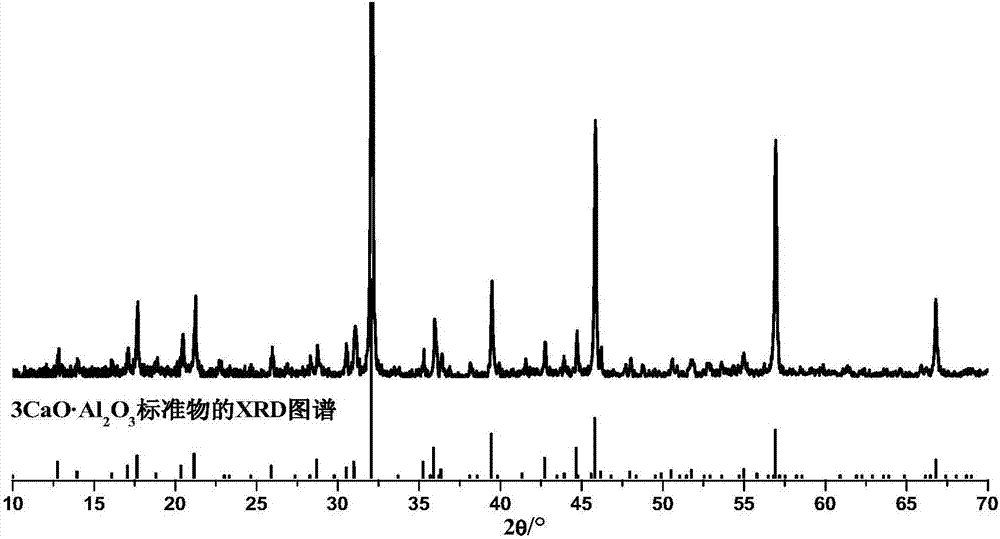

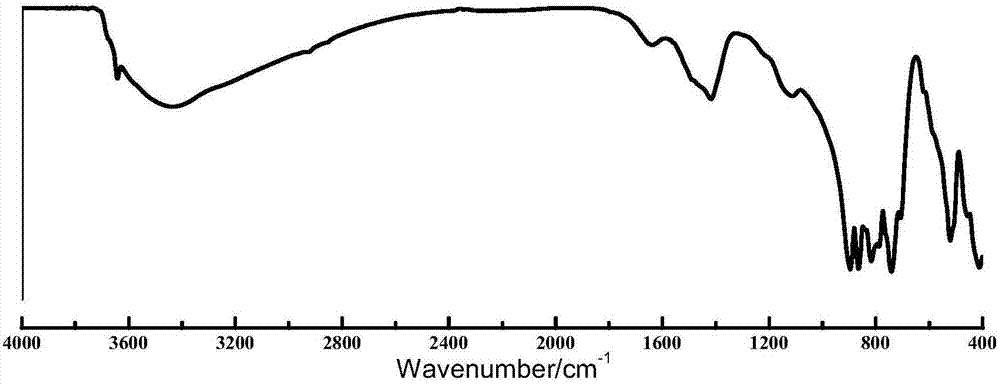

A method for preparing tricalcium aluminate using spark plasma sintering technology

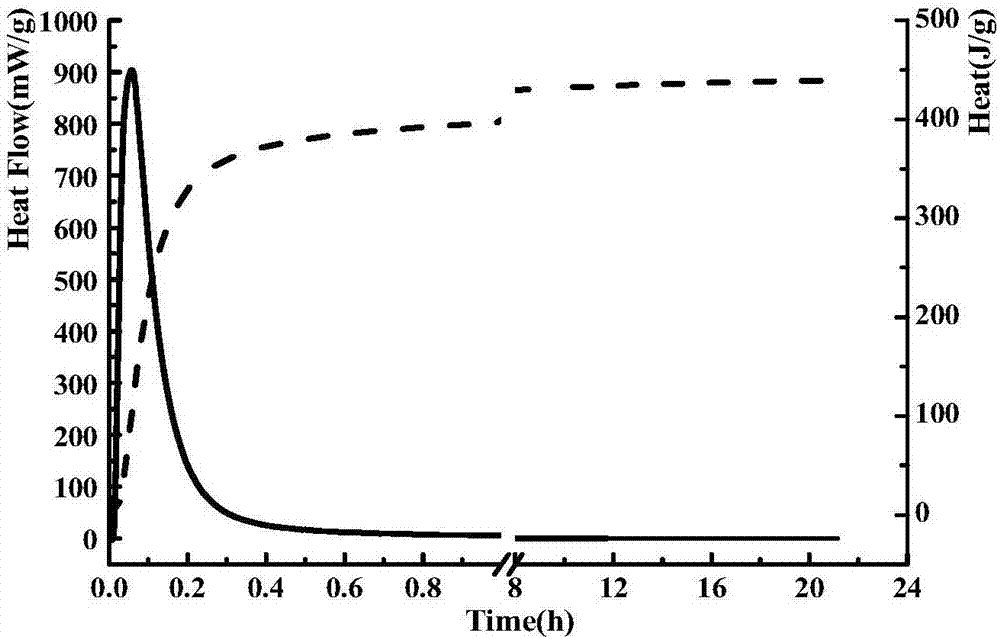

A technology of discharge plasma and tricalcium aluminate, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/aluminum oxide/aluminum hydroxide, sustainable manufacturing/processing, etc. Long cycle and other problems, to achieve the effect of reduced energy consumption and cost, irregular particle shape, and good hydration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Objective: To prepare 20.00g of tricalcium aluminate.

[0041] The oxide form 3CaO Al according to the chemical formula of tricalcium aluminate 2 o 3 , the calculated CaO content is 62.27%, Al 2 o 3 The content is 37.73%. According to the mass of tricalcium aluminate to be prepared is 20.00g, the mass of CaO in the sample after sintering is calculated to be 20.00×62.27%=12.45g.

[0042] According to the conservation of Ca element mass, the analytically pure calcium carbonate CaCO is calculated as 1.7847 times the mass of CaO 3 The required amount is 12.45×1.7847=22.22g;

[0043] Analytical Pure Calcium Carbonate CaCO 3 0.3396 times the mass to calculate the required analytically pure γ-phase alumina γ-Al 2 o 3 The mass of is 22.22×0.3396=7.55g.

[0044] Calculation and analysis of pure calcium carbonate CaCO 3 and analytically pure γ-phase activated alumina γ-Al 2 o 3 The total mass of the powder is 22.22+7.55=29.77g, and the required ball mass is calculated...

Embodiment 2

[0049] Purpose: To prepare 15.00 g of tricalcium aluminate.

[0050] The oxide form 3CaO Al according to the chemical formula of tricalcium aluminate 2 o 3 , the calculated CaO content is 62.27%, Al 2 o 3 The content is 37.73%. According to the mass of tricalcium aluminate to be prepared is 15.00g, the mass of CaO in the sample after sintering is calculated to be 15.00×62.27%=9.34g.

[0051] According to the conservation of Ca element mass, the analytically pure calcium carbonate CaCO is calculated as 1.7847 times the mass of CaO 3 The required amount is 9.34×1.7847=16.67g;

[0052] Analytical Pure Calcium Carbonate CaCO 3 0.3396 times the mass to calculate the required analytically pure γ-phase alumina γ-Al 2 o 3 The mass of is 16.67×0.3396=5.66g.

[0053] Calculation and analysis of pure calcium carbonate CaCO 3 and analytically pure γ-phase activated alumina γ-Al 2 o 3 The total mass of 16.67+5.66=22.33g, according to 4 times of the total mass of the powder mate...

Embodiment 3

[0058] Purpose: To prepare 10.00 g of tricalcium aluminate.

[0059] The oxide form 3CaO Al according to the chemical formula of tricalcium aluminate 2 o 3 , the calculated CaO content is 62.27%, Al 2 o 3 The content is 37.73%. According to the mass of tricalcium aluminate to be prepared is 10.00g, the mass of CaO in the sample after sintering is calculated to be 10.00×62.27%=6.23g.

[0060] According to the conservation of Ca element mass, the analytically pure calcium carbonate CaCO is calculated as 1.7847 times the mass of CaO 3 The required amount is 6.23×1.7847=11.12g;

[0061] Analytical Pure Calcium Carbonate CaCO 3 0.3396 times the mass to calculate the required analytically pure γ-phase alumina γ-Al 2 o 3 The mass of is 11.12×0.3396=3.78g.

[0062] Calculation and analysis of pure calcium carbonate CaCO 3 and analytically pure γ-phase activated alumina γ-Al 2 o 3 The total mass of 11.12+3.78=14.90g, according to 4 times the total mass of the powder materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com