Method for treating nitrobenzene wastewater

A technology for nitrobenzene and wastewater, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of debris loss, large amount of dissolved iron, and skyrocketing treatment costs, and achieve energy saving Cost, improved degradation rate, and significant removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

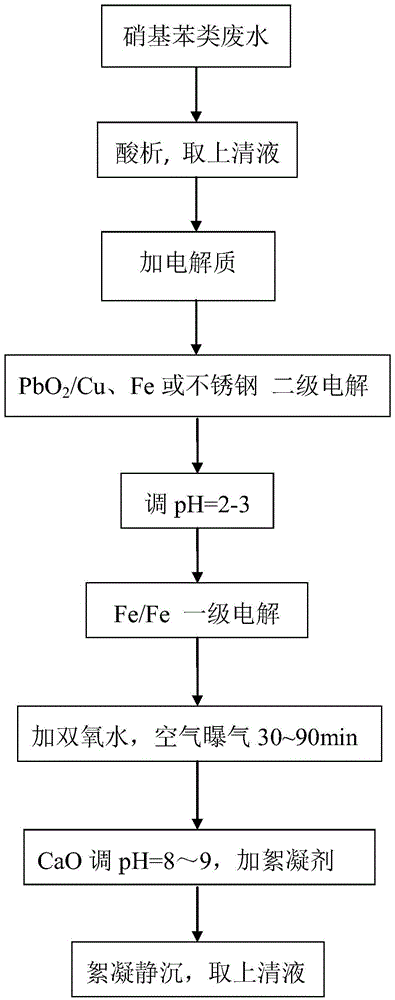

[0038] The method that present embodiment handles nitrobenzene wastewater, the steps are:

[0039] a.Acid analysis

[0040] Take wastewater with an initial COD concentration of 30,000 mg / L and a nitrobenzene content of 7 mg / L, add inorganic acid (sulfuric acid) to adjust the pH value of the wastewater to 1.5-2.5 (preferably pH=1.5), and stand still to take the wastewater supernatant for treatment Liquid, the present embodiment treatment liquid is 500ml;

[0041] b. Electrocatalytic Advanced Oxidation

[0042] Electrolyte NaCl solid is added to the treatment solution, and the NaCl mass contained in the NaCl solid is 2‰ of the treatment solution mass; it enters the electrocatalytic advanced oxidation electrolytic cell, the anode is a titanium-based lead dioxide electrode, the cathode is a copper electrode, and the electrode spacing is 2cm. Current I=3A, voltage U=4V, electrolysis time t=2h, that is, the power added per unit volume of wastewater is 12000Ah / m 3 , wherein the el...

Embodiment 2

[0051] The method that present embodiment handles nitrobenzene wastewater, the steps are:

[0052] a.Acid analysis

[0053] Take wastewater with an initial COD concentration of 5000mg / L and a nitrobenzene content of 3mg / L, add inorganic acid (hydrochloric acid) to adjust the pH value of the wastewater to 1.5-2.5 (preferably pH=2.5), and leave the wastewater supernatant for treatment Liquid, the present embodiment treatment liquid is 500ml;

[0054] b. Electrocatalytic Advanced Oxidation

[0055] The electrolyte NaCl aqueous solution is added to the treatment solution, and the added NaCl aqueous solution contains 1‰ of the NaCl mass of the treatment solution; enters the electrocatalytic advanced oxidation electrolytic cell, the anode is a titanium-based lead dioxide electrode, the cathode is a stainless steel electrode, and the electrode spacing is 3.5 cm, current I=3A, voltage U=5V, electrolysis time t=0.5h, that is, the power added per unit volume of wastewater is 3000Ah / m ...

Embodiment 3

[0064] The method that present embodiment handles nitrobenzene wastewater, the steps are:

[0065] a.Acid analysis

[0066] Take wastewater with an initial COD concentration of 10000mg / L and a nitrobenzene content of 5mg / L, add inorganic acid (nitric acid) to adjust the pH value of the wastewater to 1.5-2.5 (preferably pH=2), and stand still to take the wastewater supernatant for treatment Liquid, the present embodiment treatment liquid is 500ml;

[0067] b. Electrocatalytic Advanced Oxidation

[0068] Electrolyte NaCl solid is added to the treatment liquid, and the NaCl mass contained in the NaCl solid is 1‰ of the treatment liquid mass; it enters the electrocatalytic advanced oxidation electrolytic cell, the anode is a titanium-based lead dioxide electrode, the cathode is an iron electrode, and the electrode distance is 3cm. Current I=3A, voltage U=4.5V, electrolysis time t=1h, that is, the power added per unit volume of wastewater is 6000Ah / m 3 , wherein the electrocatal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com