Preparation method of graphene oxide composite gel applicable to heavy metal adsorption

A graphene composite, composite gel technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of limited number of oxygen-containing functional groups, and achieve excellent mechanical properties, raw materials are easily available, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

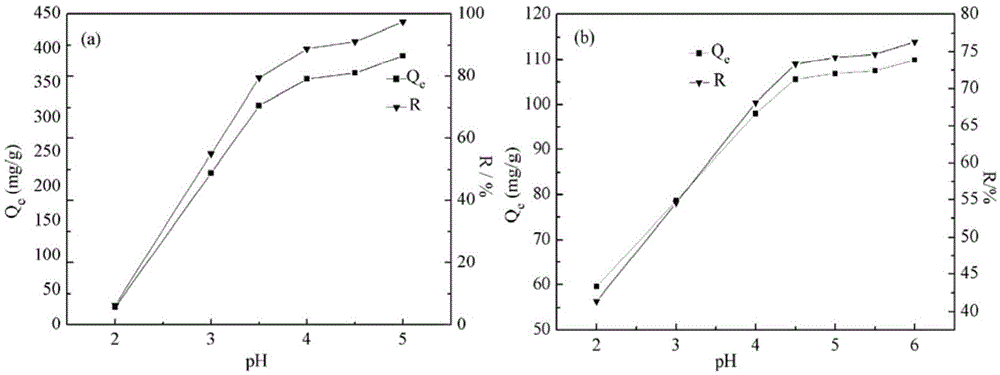

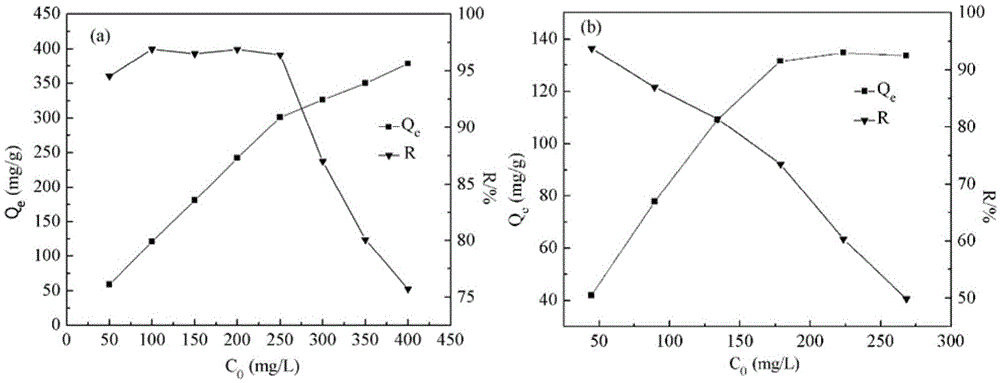

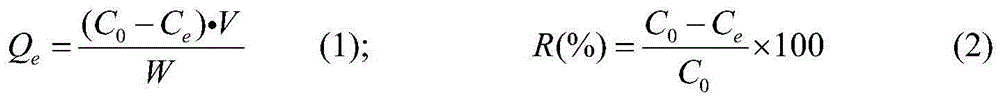

Image

Examples

Embodiment 1

[0032] A preparation method for a graphene oxide composite gel applied to heavy metal adsorption, the specific steps are as follows:

[0033] ①Weigh 6.67g of prefabricated 3%wt graphene oxide hydrogel (containing 200mg of pure graphene oxide) in a small beaker, add 30mL of distilled water and stir for 1-2min, then put it in an ultrasonic cleaner for ultrasonic dispersion for 30min, stop the ultrasonication and drop Add concentrated ammonia water to adjust the pH of the suspension to 10.0-11.0;

[0034] ②Use a 50mL graduated cylinder to take 13.0mL of the pre-made sodium acrylate solution with a concentration of 0.388g / mL and pour it into a small beaker, adjust the pH to 10.0-11.0 with 0.1mol / L NaOH solution, and then add distilled water to make about 40mL of the solution;

[0035] ③ Accurately weigh 5.0g of acrylamide, add distilled water to a small beaker, and stir with a glass rod to fully dissolve it to form a transparent solution of about 40;

[0036] ④Put the liquids obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com