Graphene-supported silicon quantum dot negative electrode material and preparation method and application thereof

A technology of silicon quantum dots and anode materials, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc. and other problems, to achieve the effect of good scalability, shortened diffusion distance, and improved kinetics of lithium storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

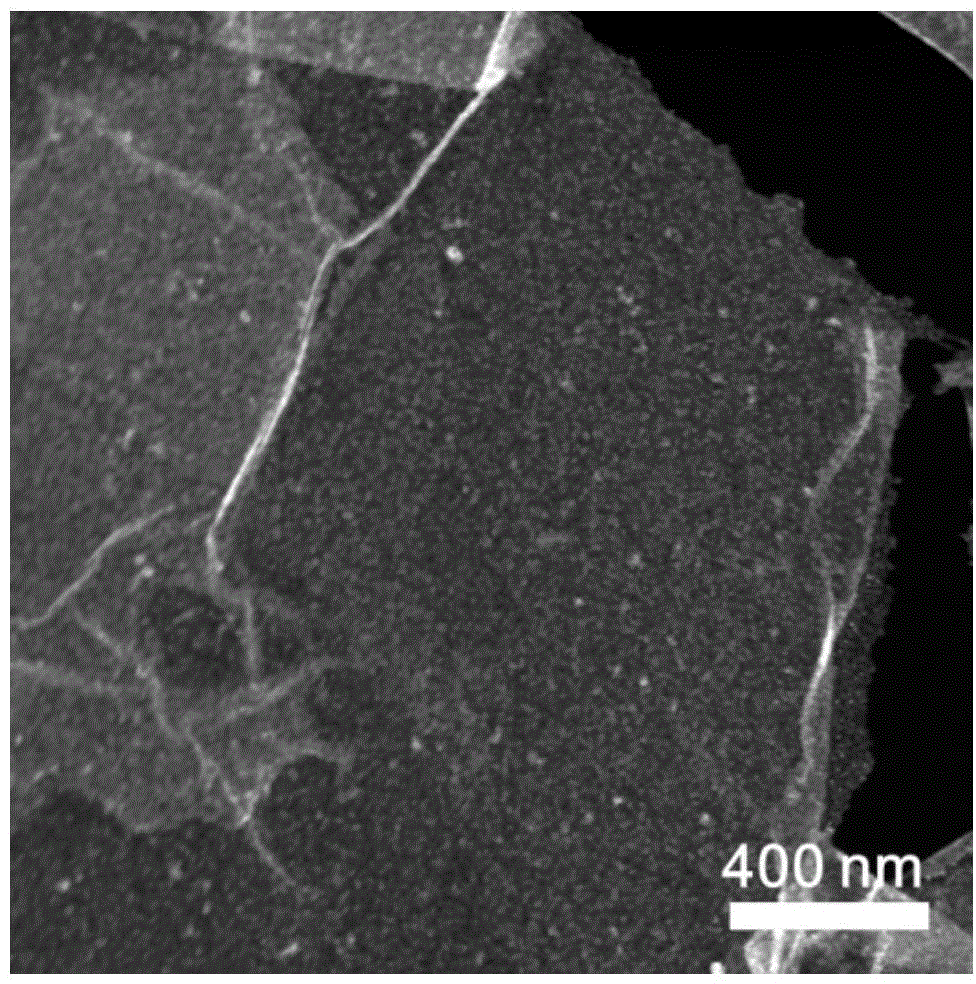

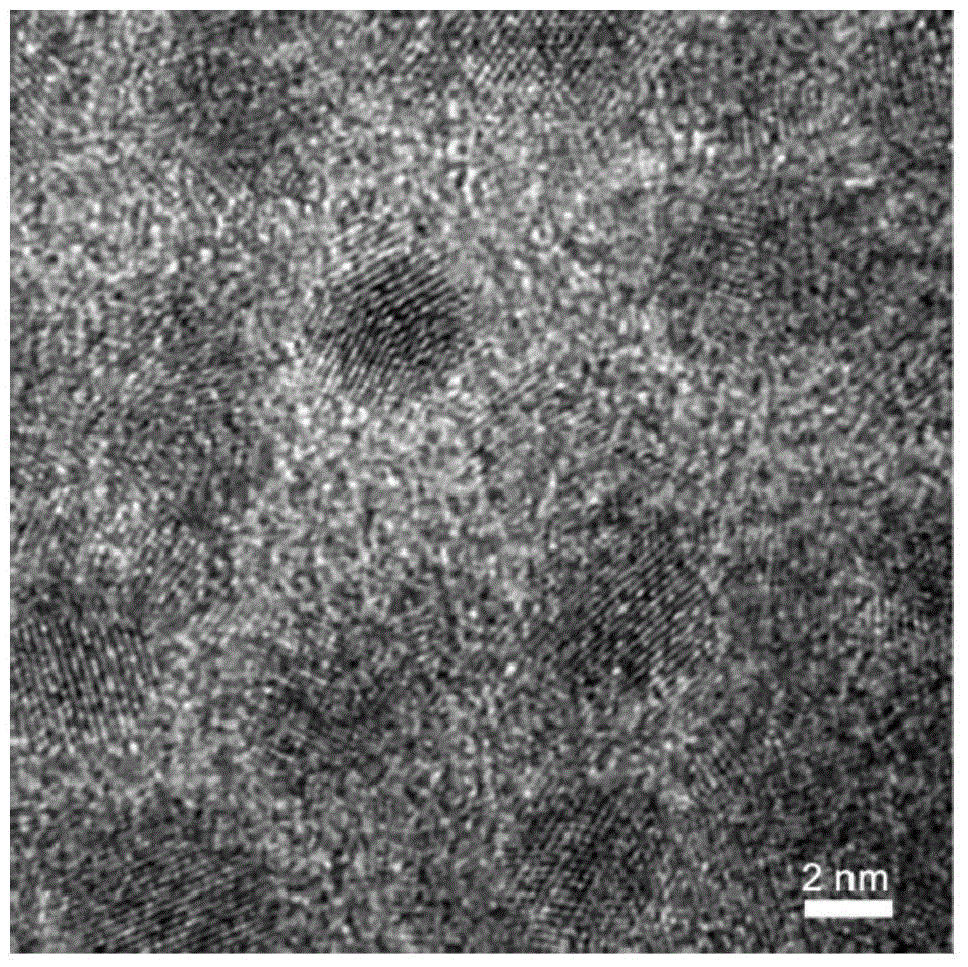

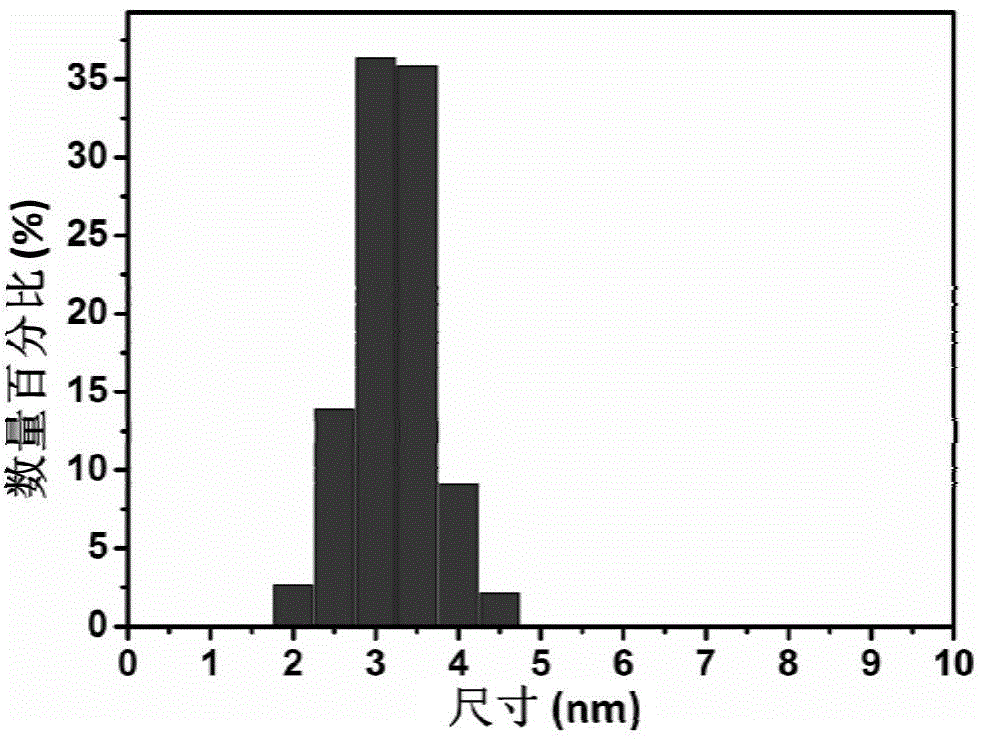

[0034] (1) Mix 3-aminopropyltriethoxysilane and sodium citrate pre-dissolved in water according to a mass ratio of 5:1, then transfer to a solvothermal reaction kettle, and place it at a constant temperature of 180°C for 2 hours, Dialysis to remove unreacted raw materials to obtain uniform 3nm silicon quantum dots;

[0035] (2) After mixing uniform silicon quantum dots with graphene oxide, adjust the pH value of the solution to 3, and after further stirring, obtain silicon quantum dots supported by graphene oxide;

[0036] (3) The silicon quantum dots supported by graphene oxide were treated at 300° C. for 5 hours under a hydrogen atmosphere to prepare silicon quantum dots supported by graphene.

[0037] The obtained graphene-supported silicon quantum dots, the binder polyvinylidene fluoride (PVDF), and the conductive agent acetylene black are uniformly mixed in N-methylpyrrolidone (NMP) to prepare a slurry, which is then coated on On the copper foil current collector, after ...

Embodiment 2

[0040](1) Mix triphenylsilylamine and sodium borohydride pre-dissolved in water according to a mass ratio of 1:1, then transfer it to a solvothermal reaction kettle, and place it at a constant temperature of 400°C for 0.5 hours, then dialyze to remove untreated The raw material for the reaction is to obtain uniform 30nm silicon quantum dots;

[0041] (2) After mixing uniform silicon quantum dots with graphene oxide, adjust the pH value of the solution to 1, and after further stirring, obtain silicon quantum dots supported by graphene oxide;

[0042] (3) The silicon quantum dots supported by graphene oxide were treated at 900° C. under an argon atmosphere for 0.5 hours to prepare silicon quantum dots supported by graphene.

[0043] Subsequent tests were as in Example 1. At a current density of 10A / g, the graphene-supported silicon quantum dot still has a specific capacity as high as 655mAh / g; after 300 cycles at a current density of 2A / g, the capacity retention rate can reach ...

Embodiment 3

[0045] (1) Mix divinyltriaminopropyltrimethoxysilane and sodium sulfite pre-dissolved in water according to a mass ratio of 10:1, then transfer it to a solvothermal reaction kettle, place it at a constant temperature of 120°C for 12 hours, and dialyze Remove unreacted raw materials to obtain uniform 15nm silicon quantum dots;

[0046] (2) After mixing uniform silicon quantum dots with graphene oxide, adjust the pH value of the solution to 7, and after further stirring, obtain silicon quantum dots supported by graphene oxide;

[0047] (3) The silicon quantum dots supported by graphene oxide were treated at 150° C. for 12 hours under a mixed atmosphere of argon and hydrogen to prepare silicon quantum dots supported by graphene.

[0048] Subsequent tests were as in Example 1. At a current density of 20A / g, the graphene-supported uniform ultra-small silicon quantum dots still have a specific capacity of 595mAh / g; after 450 cycles at a current density of 2A / g, the capacity retenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com