Rhizoma anemarrhenae effective part as well as preparation method and application thereof

A technology of effective parts and Anemarrhena, which is applied to medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problems that the extracts have not been successfully developed into drugs, etc., to improve the glucose tolerance of rats and have strong effects , significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

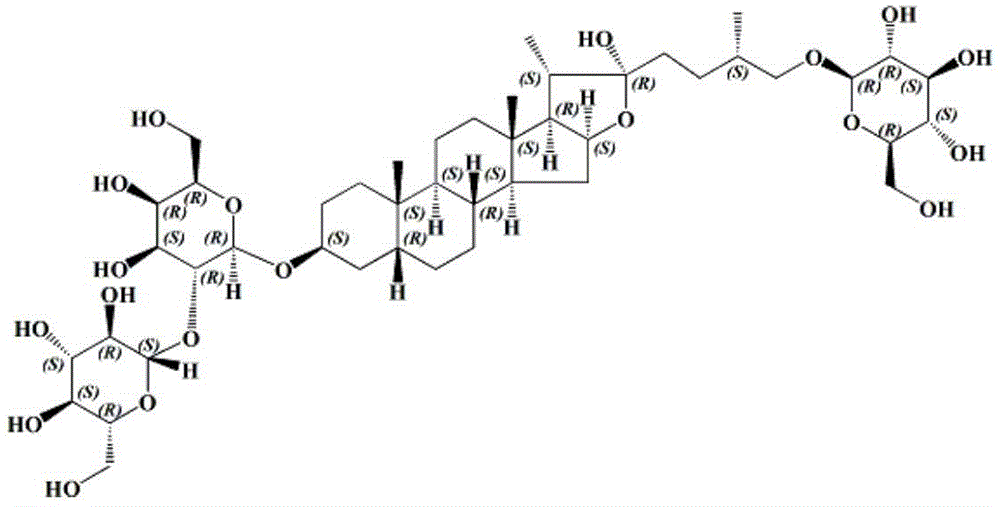

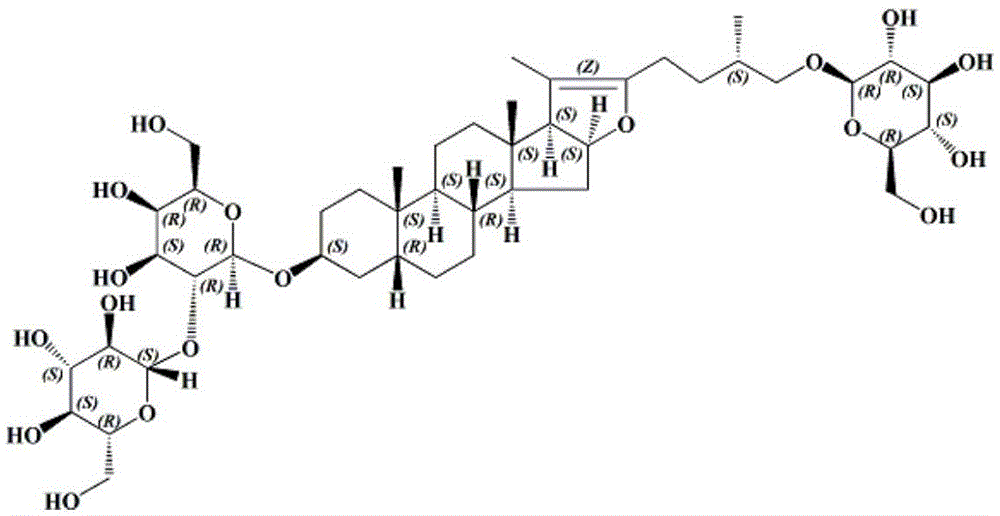

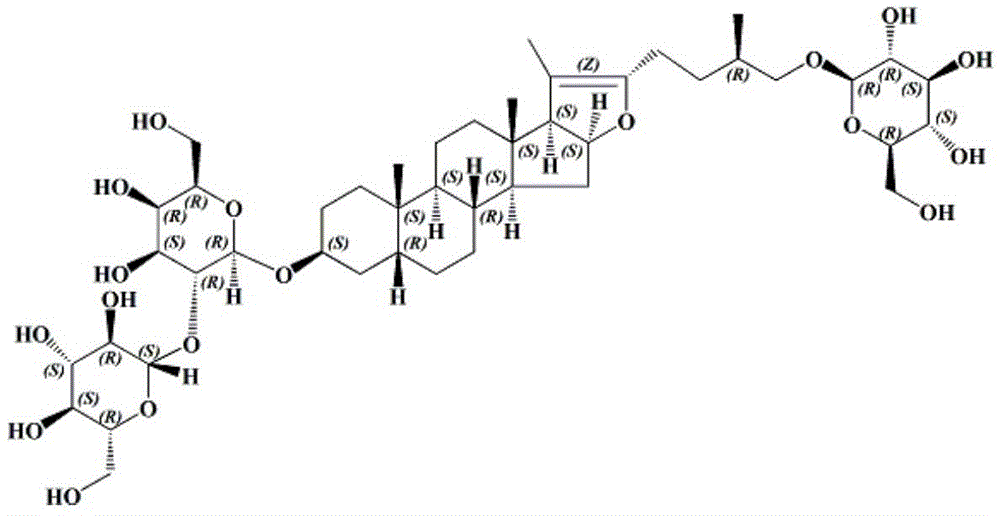

Image

Examples

Embodiment 1

[0042] Preparation of the effective part of Anemarrhena:

[0043] S1. Grinding Anemarrhena anemarrhena with 80% ethanol volume fraction and extracting twice by reflux, 1 hour each time, the ratio of the amount of ethanol to the amount of raw material Anemarrhena anemarrhena is 8mL: 1g; filter, and concentrate the filtrate until there is no ethanol smell, known mother extract;

[0044] S2. Add water to dissolve, adjust the relative density of Anemarrhena extract to 1.045-1.055 (40-45°C), apply macroporous resin for adsorption, and the sample loading flow rate is 1BV / h; after the sample is loaded, use 5BV of water to elute and remove impurities , the flow rate is 1BV / h; it is 60% ethanol elution with 6BV volume fraction again, and the flow rate is 0.5BV / h; collect the ethanol eluent, and after concentrating and drying, the parent effective part is known; the consumption of macroporous resin is 1L macroporous resin for dry extract of Anemarrhena anemarrhena extract prepared in 0...

Embodiment 2

[0053] Preparation of the effective part of Anemarrhena:

[0054] S1. Grinding Anemarrhena anemarrhena with 80% ethanol and refluxing extraction twice, 1 hour each time, the ratio of the amount of ethanol to the amount of raw material Anemarrhena anemarrhena is 10mL: 1g; filter, and concentrate the filtrate until there is no ethanol smell, known mother extract;

[0055] S2. Add water to dissolve, adjust the relative density of Anemarrhena extract to 1.045-1.055 (40-45°C), apply macroporous resin for adsorption, and sample loading flow rate is 1.5BV / h; after sample loading, wash with 3BV of water to remove Miscellaneous, flow rate is 1.5BV / h; It is 70% ethanol eluting with 6BV volume fraction again, and flow rate is 1BV / h; Collect ethanol eluate, promptly know parent effective part after concentrating and drying; The consumption of macroporous resin is For every 0.4kg of dry extract of the Anemarrhena anemarrhena extract prepared in step S1, 1L of macroporous resin was used. ...

Embodiment 3

[0058] Preparation of the effective part of Anemarrhena:

[0059] S1. Grinding Anemarrhena anemarrhena with 80% ethanol volume fraction and extracting twice by reflux, 1 hour each time, the ratio of the amount of ethanol to the amount of raw material Anemarrhena anemarrhena is 8mL: 1g; filter, and concentrate the filtrate until there is no ethanol smell, known mother extract;

[0060] S2. Add water to dissolve, adjust the relative density of Anemarrhena extract to 1.045-1.055 (40-45°C), apply macroporous resin for adsorption, and sample loading flow rate is 0.5BV / h; after sample loading, wash with 5BV of water to remove miscellaneous, the flow rate is 0.5BV / h; then elute with 5BV volume fraction of 60% ethanol, the flow rate is 0.5BV / h; collect the ethanol eluate, concentrate and dry to know the effective part of the mother; the amount of macroporous resin Use 1L macroporous resin for every 0.2kg dry extract of Anemarrhena extract prepared in step S1.

[0061] As a result, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com