SCR denitration catalyst and preparation method thereof

A denitration catalyst, catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of affecting the service life of the catalyst, high preparation cost, catalyst corrosion, etc. value, reduce production costs, and expand the effect of application technology fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

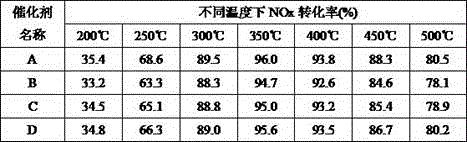

Examples

Embodiment 1

[0030] After the serpentine is ground, sieve the sample of 300~400 objects, then it is 300 with sorbitol monostearate, polyoxyethylene sorbitan monostearate, water and 25wt% ammoniacal liquor according to mass ratio: Mixed at a ratio of 5:3:100:15, then placed in a water bath at 80°C for reflux treatment for 4 hours, and then transferred the obtained material to an oven at 105°C for 10 hours.

[0031] Weigh a certain amount of tetrabutyl titanate and diacetone acryloyl ammonium acetate dropwise into the nitric acid solution with a concentration of 15wt%, stir at room temperature for 30min, then continue the aging treatment for 6h, then weigh a certain amount of surface-treated Serpentine is added to the above mixed solution, wherein the mass ratio of serpentine, tetrabutyl titanate, diacetone acryloyl ammonium acetate and nitric acid is 10:120:2:5, and the above mixture is mixed at 500rpm / min After treatment under the same conditions for 18 hours, the solution was slowly evapo...

Embodiment 2

[0037] The 300~400 mesh serpentine sample, sorbitan monostearate, polyoxyethylene sorbitan monostearate, water and 25wt% ammonia water are in a mass ratio of 300:5:3:130:

[0038] After mixing at a ratio of 30, they were placed in a water bath at 50°C for reflux treatment for 6 hours, and then the resulting material was transferred to an oven at 120°C for 6 hours. A certain amount of tetrabutyl titanate and diacetone acryloyl ammonium acetate were respectively weighed and added dropwise to a nitric acid solution with a concentration of 15 wt%, stirred at room temperature for 30 min, and then aged for 6 h. Then weigh a certain amount of surface-treated serpentine and add it to the above mixed solution, wherein the mass ratio of serpentine, tetrabutyl titanate, diacetone acryloyl ammonium acetate and nitric acid is 10:28:0.5:1.0 , the above mixture was treated at 500rpm / min for 24h, then the solution was slowly evaporated to dryness in a water bath at 70°C, and the obtained prod...

Embodiment 3

[0041] The 300~400 mesh serpentine sample, sorbitol monostearate, polyoxyethylene sorbitan monostearate, water and 20wt% ammonia water are in a mass ratio of 300:5:3:110:

[0042] After mixing at a ratio of 18, they were placed in a water bath at 60°C for reflux treatment for 5 hours, and then the resulting material was transferred to an oven at 110°C for 8 hours. A certain amount of tetrabutyl titanate and diacetone acryloyl ammonium acetate were respectively weighed and added dropwise to the nitric acid solution with a concentration of 10wt%, stirred at room temperature for 25 minutes, and then continued to be aged for 4 hours. Then weigh a certain amount of surface-treated serpentine and add it to the above mixed solution, wherein the mass ratio of serpentine, tetrabutyl titanate, diacetone acryloyl ammonium acetate and nitric acid is 10:50:1:1.5 , the above mixture was treated at 650rpm / min for 22h, then the solution was slowly evaporated to dryness in a water bath at 75°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com