A kind of preparation method of ultra-soft and lightweight graphene electric heating film

A technology of graphene and electric heating film, which is applied in the direction of graphene, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problem of heating elements without automatic constant temperature and power compensation functions, short service life of electric heating elements, and complex structure of electric heating systems and other issues, to achieve good toughness, rapid heat dissipation, and a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

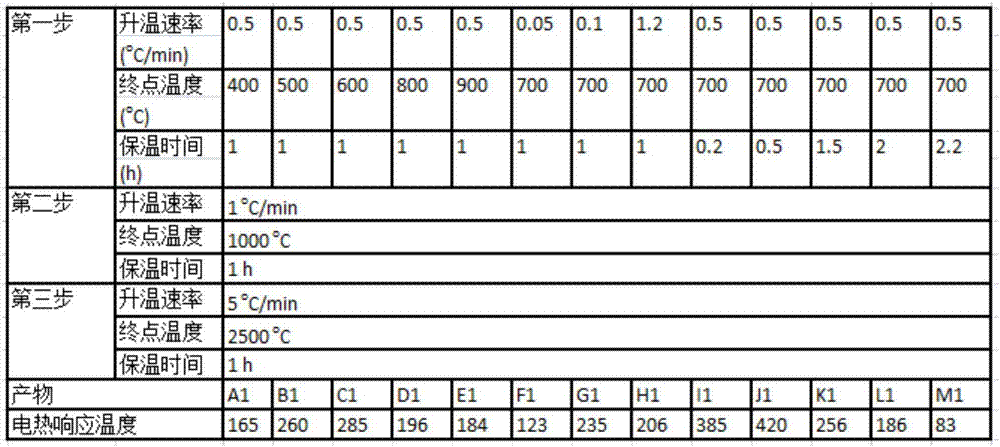

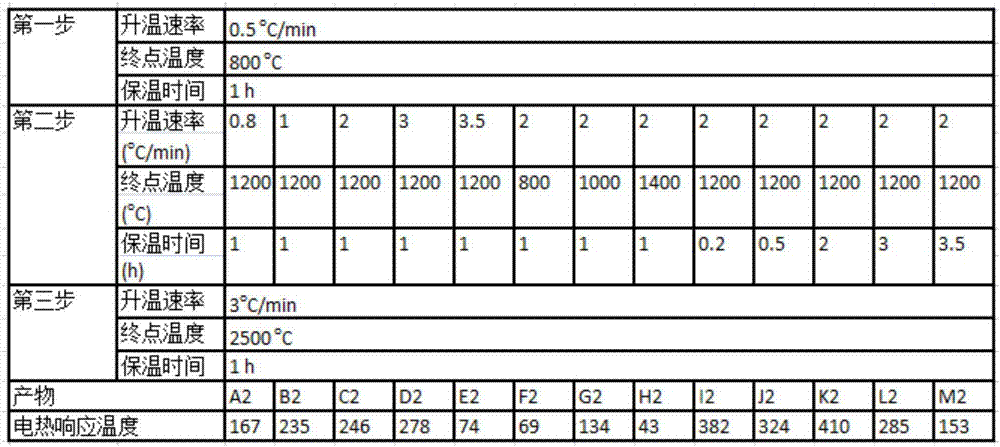

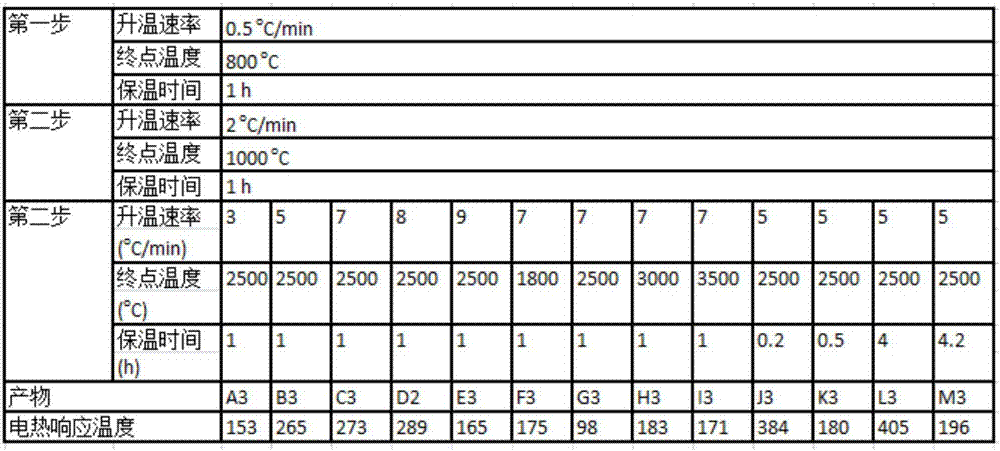

Method used

Image

Examples

preparation example Construction

[0024] The preparation device with an in-line outlet used in the present invention is a prior art, which is a cuboid structure with a in-line die opening in the middle, and the in-line die opening is a gradually narrowing flow channel. The gradually narrowed flow channel can effectively increase the force of the flow field on the graphene sheet, which is conducive to the formation of a regular orientation structure of the graphene dispersion system.

[0025] This embodiment is only used to further illustrate the present invention, and should not be understood as limiting the protection scope of the present invention. Those skilled in the art make some non-essential changes and adjustments according to the content of the above invention, which all belong to the protection scope of the present invention .

Embodiment 1-1

[0028] (1) Slowly add potassium permanganate into the rapidly stirring concentrated sulfuric acid at -10°C. After fully dissolving, add graphite, stir slowly at 60 rpm for 2 hours, then stop stirring. After reacting for 6 hours, broadly distributed graphite oxide crystals were obtained respectively; there were many fragments in the graphite oxide wafers obtained at the two temperatures, which made the corresponding graphene oxide also have many fragments.

[0029] (2) The reaction solution obtained in step 1 is diluted with concentrated sulfuric acid (the dilution factor can be any multiple, and the present embodiment is diluted about 10 times), and the graphite oxide crystals are filtered out with a titanium alloy mesh sieve with a 150um aperture (140 mesh) (Reaction solution recovery), and slowly pour into rapidly stirred ice water relative to the volume of 10 times the volume of the filtered product, leave it for 2h, slowly add H2O2, to remove excess potassium permanganate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com