Biological filter device for purifying foul gas and volatile organic compounds

A volatile organic compound and biological filter technology, which is used in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problem that the biological filter is difficult to accurately control the operating parameters, affects the removal efficiency of microbial active pollutants, and is not conducive to degradation. The composition of odorous gas and other problems, to achieve the effect of saving civil construction costs, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

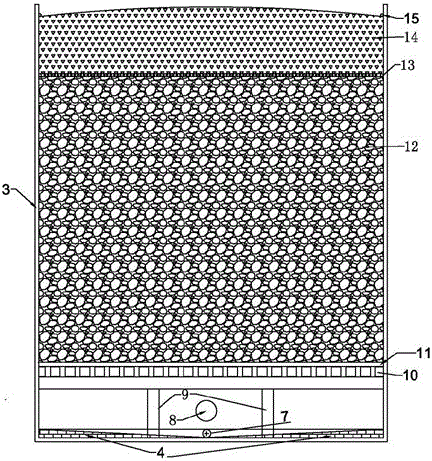

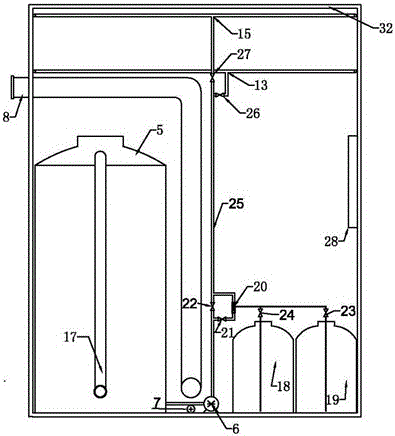

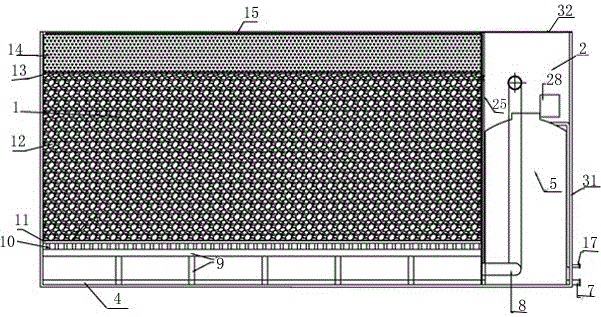

[0019] 1 biological filter filter room, 2 equipment room, 3 biological filter shell, 4 leachate slope at the bottom of the filter, 5 spray tank, 6 spray pump, 7 leachate collection pipe, 8 air intake pipe, 9 Bottom load-bearing bracket, 10 grid, 11 air distribution filter, 12 composite filler layer, 13 drip irrigation pipe, 14 top filler layer, 15 top spray pipe, 16 top sprinkler head, 17 supplementary water pipe, 18 nutrient solution tank, 19pH Value balance liquid tank, 20 Venturi mixer, 21 valve, 22 valve, 23 valve, 24 valve, 25 spray water main pipe, 26 solenoid valve, 27 solenoid valve, 28 automatic control device panel, 29 spray water inlet pipe, 30 Spray water outlet pipe, 31 cabinet door, 32 equipment room top cover

[0020] Below in conjunction with accompanying drawing, the present invention will be further described,

[0021] Depend on Figure 1-3 It can be seen that the present invention is a cuboid. The middle of the cuboid is divided into two parts by a partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com