A microscopic hot stage and sample cell system for electrochemical in-situ Raman spectroscopy

An in-situ Raman and spectroscopic measurement technology, applied in the field of electrochemical and optical analysis, can solve the problems of not considering the dynamic sample addition method, not considering the lens cooling protection, the corrosion of the Raman microscope head, etc., to achieve good thermal insulation performance, cooling Good effect, strong corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

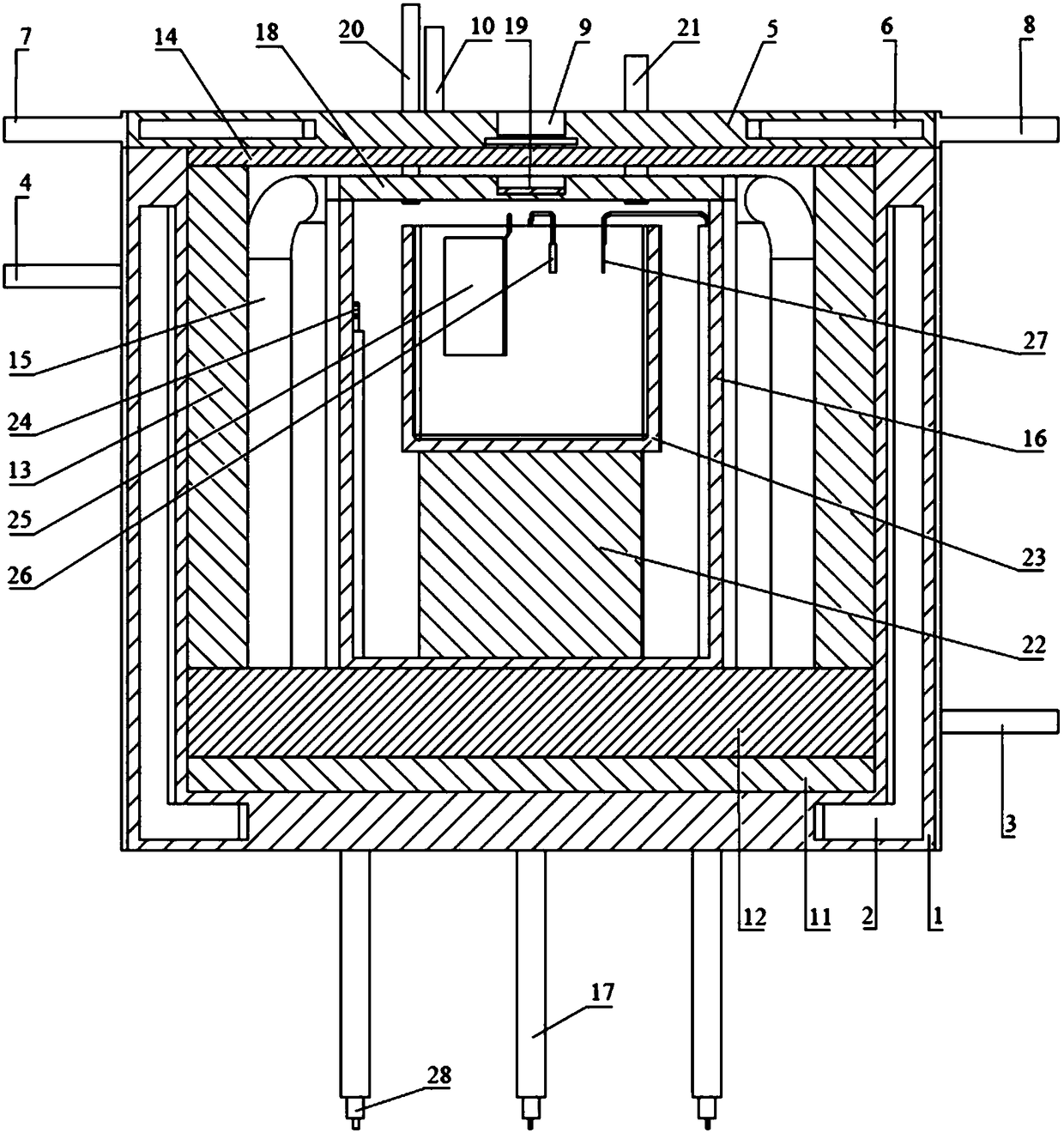

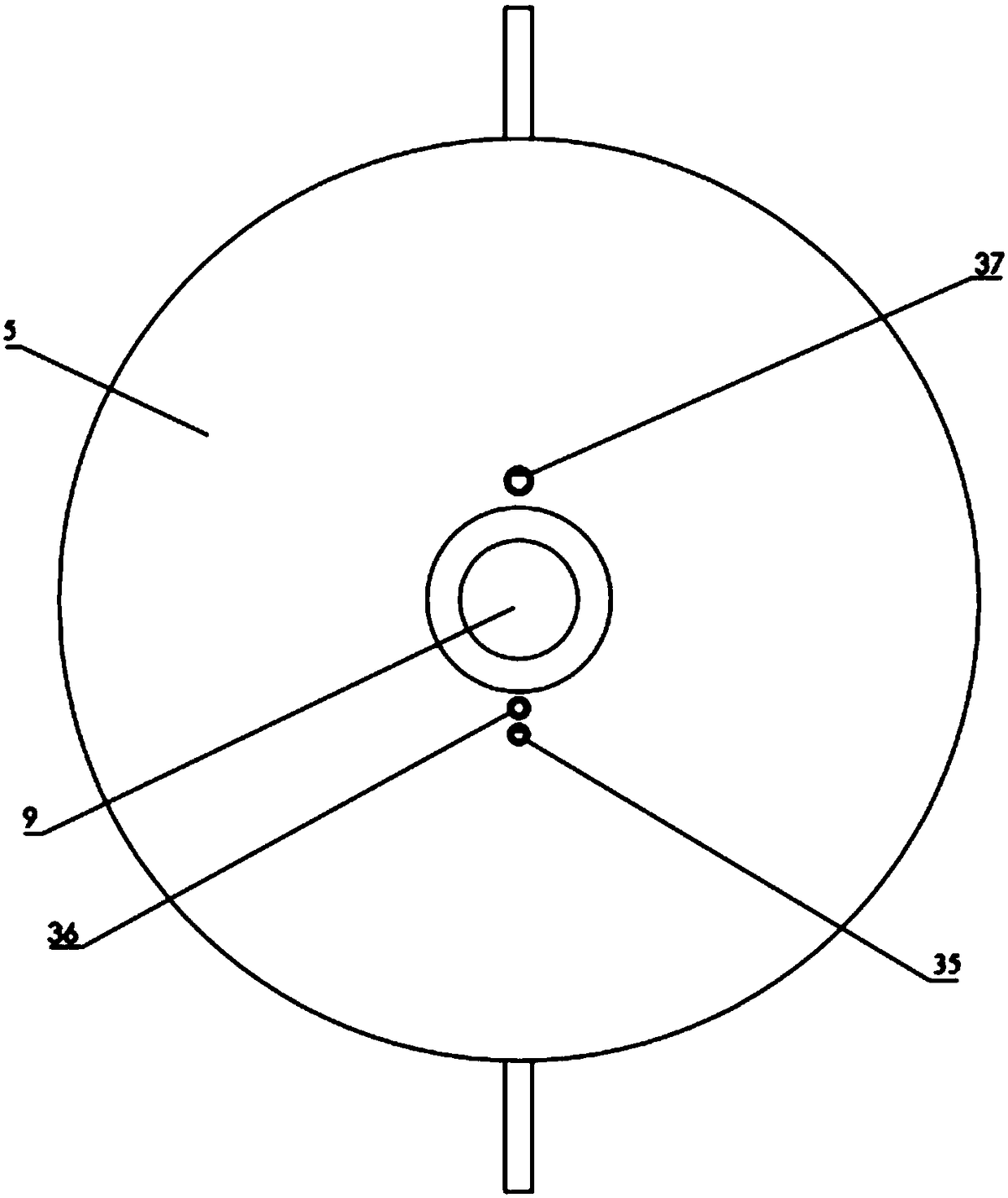

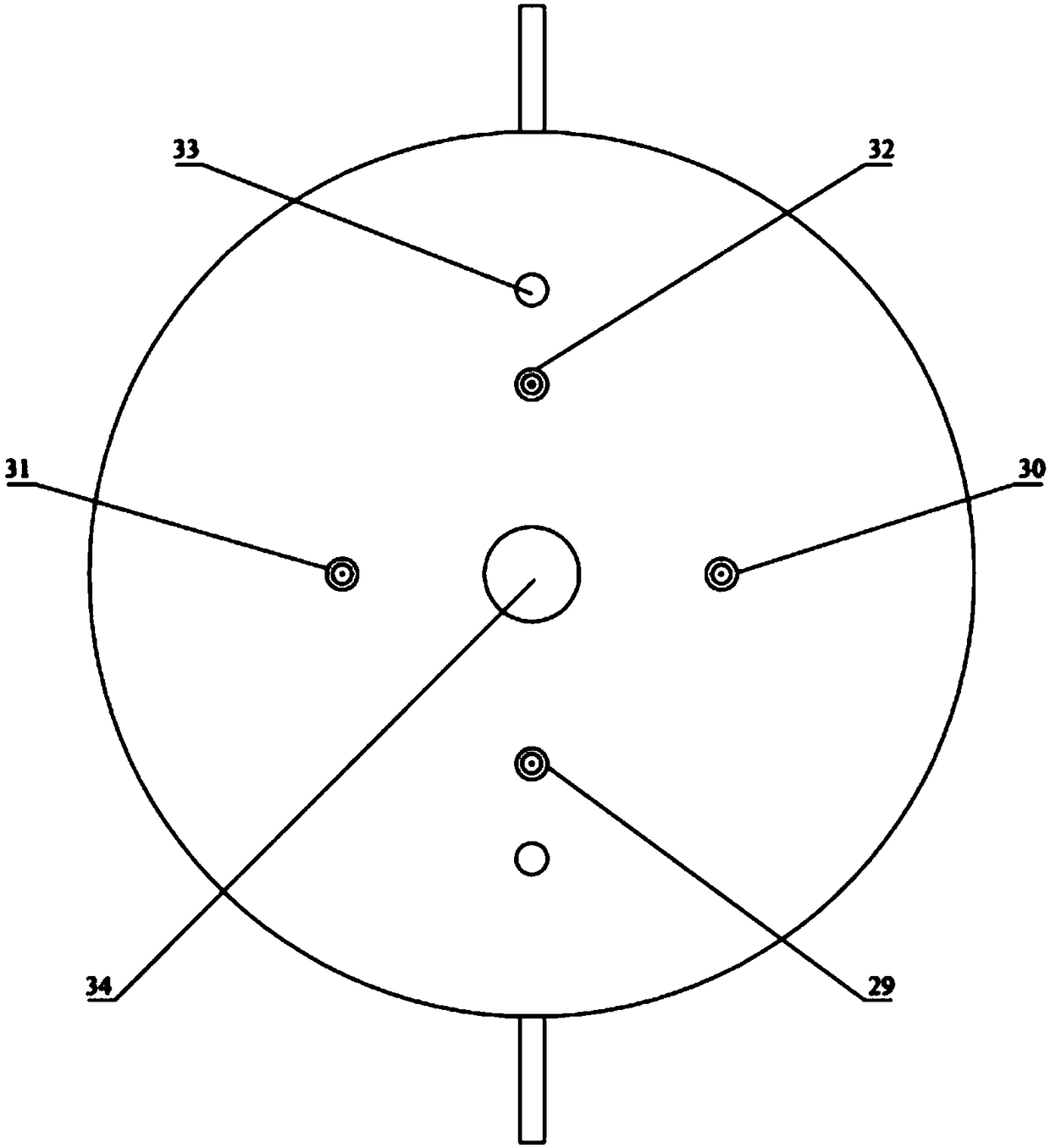

[0044] A microscopic hot stage and sample cell system for electrochemical in-situ Raman spectroscopy, such as Figure 1~3 As shown, it includes a hot stage main body 1, a hot stage cover 5, a sealed cabin, a silicon carbide rod 15, a sample pool 23 and a base 40; , the sealed cabin and the silicon carbide rod 15 are arranged on the top of the thermal insulation layer 12, and the silicon carbide rod 15 is arranged around the sealed cabin, and an annular thermal insulation layer 13 is arranged between the silicon carbide rod 15 and the inner wall of the hot stage main body 1; the sample pool 23 Placed in a sealed cabin; the outside of the bottom of the main body of the heating stage 1 is provided with a base installation hole 34 for inserting the upper pillar 41 of the base, a silicon carbide rod wire through hole 33, a thermocouple wire through hole 32, a counter electrode wire through hole 31, and a reference Electrode wire through hole 29 and working electrode wire through ho...

Embodiment 2

[0071] The microthermal stage and sample cell system for electrochemical in-situ Raman spectroscopy measurement in this embodiment are the same as those in Embodiment 1, the difference is that the system in this embodiment directly uses the sample cell as the counter electrode, and the material of the crucible used in the sample cell is graphite . Figure 10 A schematic structural diagram of the micro-heating stage and sample cell system for electrochemical in-situ Raman spectroscopy measurement of this embodiment is provided; Figure 11 A schematic diagram of the structure of the airtight cabin is provided; Figure 12 A schematic diagram of the sample cell structure is provided.

[0072] The model of the temperature controller used in conjunction with the microthermal table and sample cell system of this embodiment is CKW-3100; the Raman spectrometer is a HR800 microscopic laser Raman spectrometer; the laser is an IK3301R-G He-Cd 325nm ultraviolet laser; Microscope (lens): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com