A kind of halogen-doped lead-oxygen compound nanocrystal and its preparation method and use

A compound and nanocrystal technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of rare n-type PbY nanocrystals, achieve the effect of increasing the thickness of the active layer, improving the conversion efficiency, and increasing the built-in electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

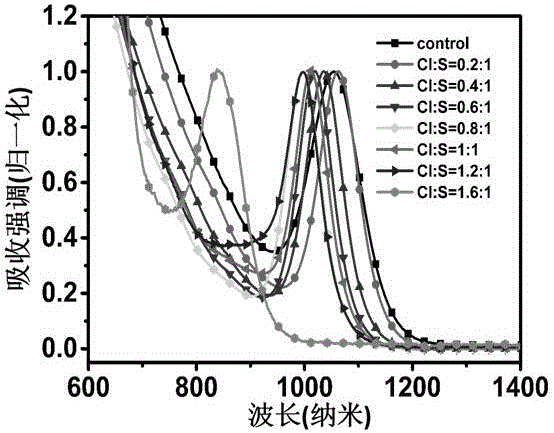

[0039] Example 1: Preparation of chlorine-doped PbS nanocrystals.

[0040] 1) Add 223 mg (1 mmol) lead oxide, 700 mg (2.5 mmol) oleic acid and 10 g 1-octadecene into a three-necked flask, stir and vacuumize at 100 °C for 1 h to obtain a lead precursor, stand-by;

[0041] 2) Nitrogen was introduced into the three-necked flask, and the temperature was adjusted to 120°C, 8.75 μL (0.1 mmol) TMSCl, 105 μL (0.5 mmol) (TMS) 2 After S and 5 mL of 1-octadecene were mixed evenly, they were quickly injected into the above-mentioned lead precursor with a syringe, and the reaction was continued for 5 min;

[0042]3) After the reaction is completed, lower the water bath to room temperature, inject 8 mL of anhydrous n-hexane, transfer the reaction solution to a centrifuge tube, add isopropanol until the reaction solution becomes cloudy, and centrifuge in a centrifuge (8000 rpm) for 5 min Finally, discard the upper layer, then dissolve it with n-hexane, add acetone and centrifuge, discard t...

Embodiment 2

[0043] Example 2: Preparation of chlorine-doped PbS nanocrystals.

[0044] 1) Add 223 mg (1 mmol) lead oxide, 700 mg (2.5 mmol) oleic acid and 10 g 1-octadecene into a three-necked flask, stir and vacuumize at 110 °C for 2 h to obtain a lead precursor, stand-by;

[0045] 2) Nitrogen gas was introduced into the three-necked flask, and the temperature was adjusted to 120°C. 17.5 μL (0.2 mmol) TMSCl, 105 μL (0.5 mmol) (TMS) 2 After S and 5 mL of 1-octadecene were mixed evenly, they were quickly injected into the above-mentioned lead precursor with a syringe, and the reaction was continued for 5 min;

[0046] 3) After the reaction is completed, lower the water bath to room temperature, inject 8 mL of anhydrous n-hexane, transfer the reaction solution to a centrifuge tube, add isopropanol until the reaction solution becomes cloudy, and centrifuge in a centrifuge (8000 rpm) for 5 min Finally, discard the upper layer, then dissolve it with n-hexane, add acetone and centrifuge, disc...

Embodiment 3

[0047] Example 3: Preparation of chlorine-doped PbS nanocrystals.

[0048] 1) Add 223 mg (1 mmol) lead oxide, 700 mg (2.5 mmol) oleic acid and 10 g 1-octadecene into a three-neck flask, stir and vacuumize at 110 °C for 1 h to obtain a lead precursor, stand-by;

[0049] 2) Infuse nitrogen gas into the three-necked flask, and adjust the temperature to 120°C, mix 27 μL (0.3 mmol) TMSCl, 105 μL (0.5 mmol) (TMS) 2 After S and 5 mL of 1-octadecene were mixed evenly, they were quickly injected into the above-mentioned lead precursor with a syringe, and the reaction was continued for 5 min;

[0050] 3) After the reaction is completed, lower the water bath to room temperature, inject 8 mL of anhydrous n-hexane, transfer the reaction solution to a centrifuge tube, add isopropanol until the reaction solution becomes cloudy, and centrifuge in a centrifuge (8000 rpm) for 5 min Finally, discard the upper layer, then dissolve it with n-hexane, add acetone and centrifuge, discard the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com