In-situ modified powder rubber and its preparation method

A powder rubber and in-situ modification technology, which is applied in the field of in-situ modified powder rubber and its preparation, can solve the problems affecting the fluidity of powder rubber, agglomeration and uneven dispersion, and fast aging reaction rate, so as to prolong aging and discoloration Problems, improvement of overall performance, effect of improvement in dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

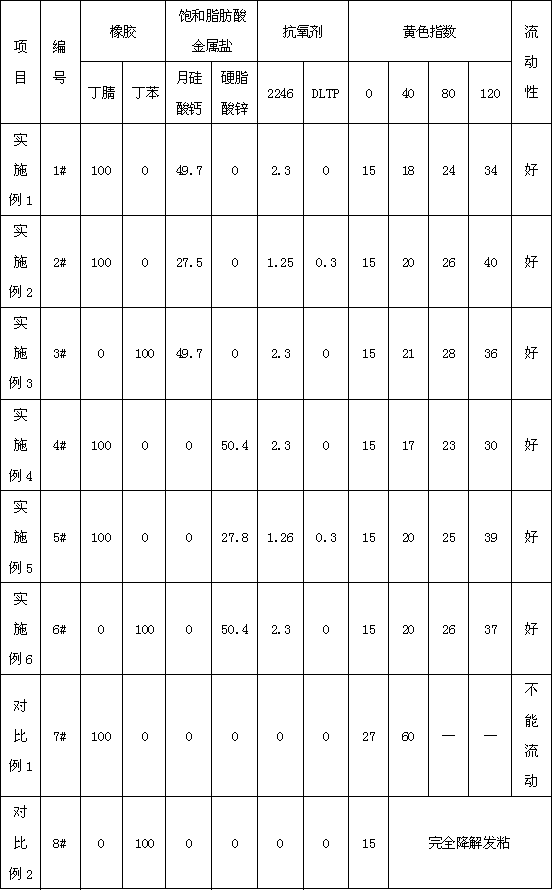

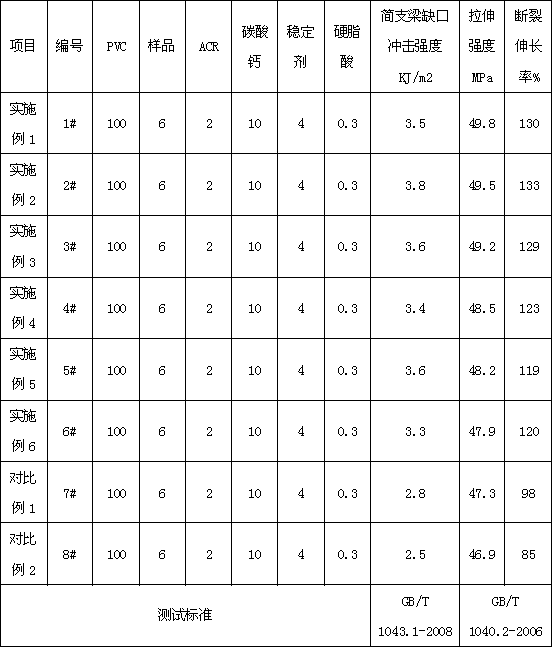

[0023] Add 110 parts of water and 6 parts of sodium hydroxide into the reaction kettle. Add 30 parts of lauric acid while stirring. After the lauric acid is completely dissolved, add nitrile latex (33% acrylonitrile, 45% gel content, Wuxi Yatai Synthetic Rubber Co., Ltd.) 165 parts, antioxidant 2246 (2,2'-methylene bis (4-methyl-6-tert-butyl phenol)) 1.5 parts, after mixing uniformly, stir at 100 rpm Add 24 parts of calcium chloride aqueous solution with a concentration of 35% at a high speed. After 20 minutes of adding, continue to stir and react for 30 minutes, and then centrifuge, wash, dry, crush and sieving, and finally get 1# calcium laurate in situ Modified powdered nitrile rubber. The specific formula is shown in Table 1, where the content of each component is calculated in parts by weight.

[0024] Rubber powder performance test: The 1# sample is aged in a 150℃ blast drying oven, and a sample is taken out every 40 minutes, and the yellow index of the sample after aging ...

Embodiment 2

[0027] In addition to adjusting the amount of nitrile latex to 300 parts, the antioxidant is adjusted to 2246 (2,2'-methylene bis (4-methyl-6-tert-butyl phenol)) 1.5 parts and DLTP (thiobis Dilauryl propionate) 0.5 parts, and the rest is the same as in Example 1. After reaction, 2# calcium laurate modified powder nitrile rubber in situ was obtained. The specific formula is shown in Table 1, where the content of each component is calculated in parts by weight

[0028] The performance test of sample 2# is the same as that of Example 1, and the results are shown in Table 1.

[0029] Except that the 2# sample is used in the preparation of PVC mixed powder, the rest is the same as in Example 1. The specific formula is shown in Table 2, and the content of each component is calculated in parts by weight. After sample preparation, mechanical and other performance test results are shown in Table 2.

Embodiment 3

[0031] Except that the nitrile rubber latex is replaced with carboxyl styrene butadiene rubber latex (solid content 40%, Wuxi Yatai Synthetic Rubber Co., Ltd.), the rest is the same as in Example 1, and 3# calcium laurate in-situ modified powder carboxyl styrene butadiene rubber is obtained by reaction . The specific formula is shown in Table 1, where the content of each component is calculated in parts by weight.

[0032] The performance test of sample 3# is the same as that of Example 1, and the results are shown in Table 1.

[0033] Except that the 3# sample is used for the preparation of PVC mixed powder, the rest is the same as in Example 1. The specific formula is shown in Table 2, and the content of each component is calculated in parts by weight. After sample preparation, mechanical and other performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com