Adhesive for lithium ion battery ceramic diaphragm and preparation method of adhesive

A technology for lithium ion batteries and ceramic separators, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problem of affecting the flatness and dimensional stability of ceramic separators, affecting the leveling performance of adhesives, and poor environmental friendliness and other problems, to achieve excellent bonding strength, reduce VOC emissions, and environmental friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

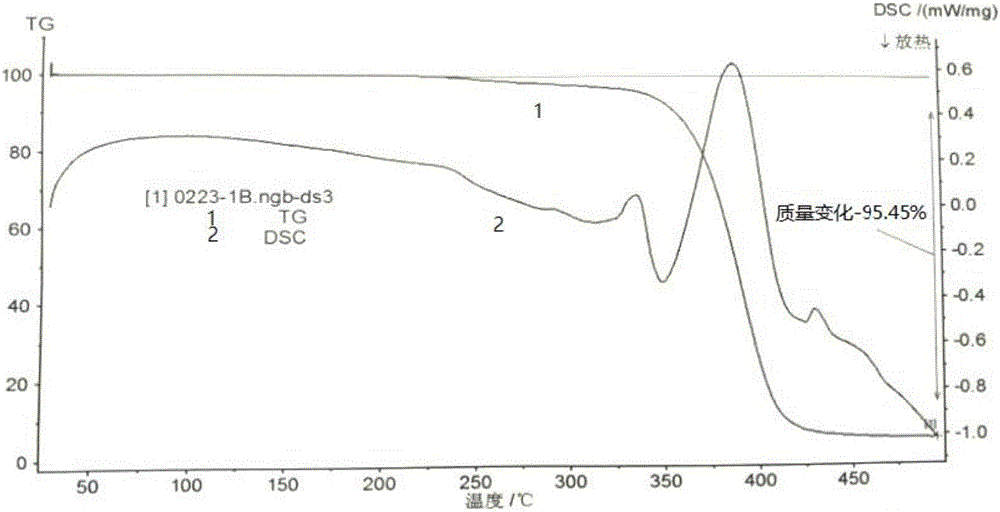

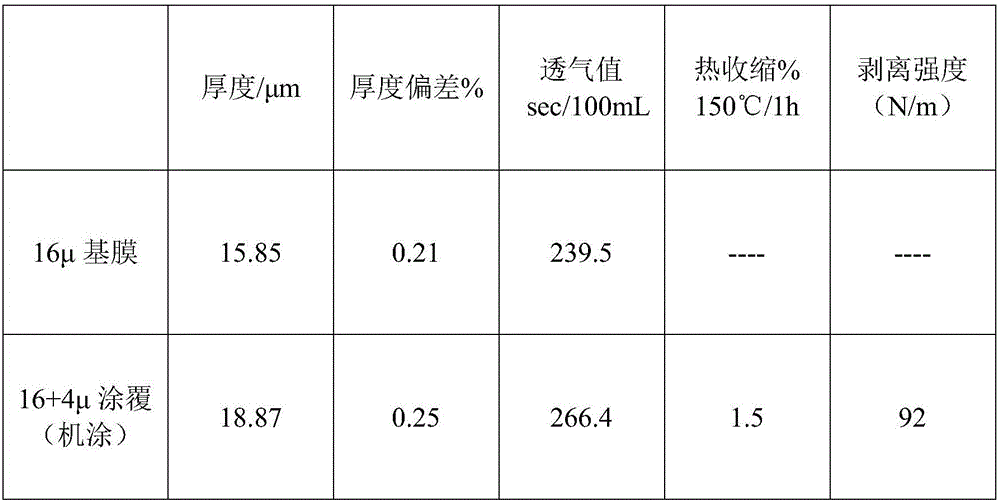

Image

Examples

Embodiment 1

[0043] In this example, SDS and sorbitan fatty acid ester compound are used as the emulsifier for the adhesive for the ceramic diaphragm, ammonium persulfate and diabolite are used as the initiator, and methacrylic acid is used as the acrylic hard monomer for polymerization. Methyl ester and acrylonitrile, acrylic soft monomers for polymerization adopt isooctyl acrylate, wherein the ratio of methyl methacrylate, acrylonitrile and isooctyl acrylate is 5:3:2 by weight.

[0044] The preparation method of the above-mentioned adhesive for ceramic diaphragm is as follows: add 10 parts of SDS, 50 parts of sorbitan fatty acid ester and 300 parts of water in a pre-emulsification bottle and mix thoroughly, and then add 375 parts of methyl methacrylate in sequence , 225 parts of acrylonitrile and 150 parts of isooctyl acrylate were stirred at a high speed at a speed of 600 rpm to disperse and form a stable pre-emulsion;

[0045] After 30 minutes, take out 100g of the pre-emulsion and add...

Embodiment 2

[0048] In this example, sodium dodecylbenzenesulfonate and sorbitan fatty acid ester are compounded as the emulsifier for the adhesive for the ceramic diaphragm, and methyl methacrylate, acrylonitrile, and isooctyl acrylate are used for polymerization. The ratio of those is 5:1:4 by weight, and all the other steps are with embodiment 1.

[0049] The prepared adhesive has a solid content of 40%, is milky white, has a particle size range of 100nm-300nm, and has a viscosity of less than 10 centipoise.

Embodiment 3

[0051] In this example, SDS and polyoxyethylene sorbitan fatty acid ester are used as the emulsifier for the adhesive for the ceramic diaphragm, methyl methacrylate and acrylonitrile are used for polymerization, and acrylic acid is used for polymerization. The soft monomer adopts isobutyl acrylate, wherein the ratio of methyl methacrylate, acrylonitrile and isobutyl acrylate is 5:2:3 by weight.

[0052] The prepared adhesive has a solid content of 45%, is milky white, has a particle size range of 100nm-300nm, and has a viscosity of 40 centipoise.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com