Concentrate supplement for lactating dairy cow

A technology of concentrate supplement and lactation period, which is applied to the field of concentrate supplement of dairy cows in lactation period, can solve the problems of high incidence of limb and foot disease, low milk protein and milk fat content, short service life of dairy cows, etc., so as to improve palatability. , the effect of improving rumen fermentation function and improving digestion utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

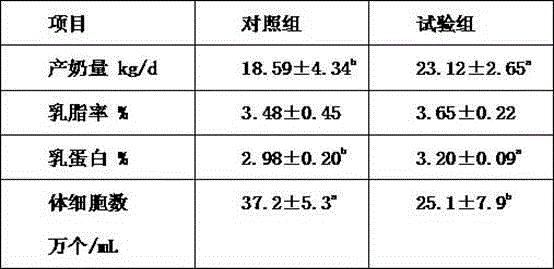

Examples

Embodiment 1

[0035] This embodiment is a concentrate supplement for dairy cows during the lactation period in Southwest China. It consists of the following components: corn: 400 parts, wheat bran: 140 parts, high-fat corn: 100 parts, 43% soybean meal 50 parts, 42 parts 150 parts of cotton meal, 80 parts of beet granule meal, 25 parts of sugarcane molasses, 15 parts of stone powder, 5 parts of calcium hydrogen phosphate, 7.5 parts of sodium chloride, 15 parts of sodium bicarbonate, 5 parts of magnesium oxide, 2.5 parts of yeast culture, 2 parts of vitamin and trace element premix, 1 part of rumen-passing lysine, 0.05 part of multidimensional electrolyte additive, 1 part of anti-fungal agent, and 1 part of mold-removing agent.

[0036] The invention improves the palatability and digestibility of the feed by strictly controlling the quality of bulk raw materials; by adding sodium bicarbonate, magnesium oxide, multidimensional electrolytes, and yeast cultures, the effect of rumen microorganisms...

Embodiment 2

[0038] This embodiment is a concentrate supplement for dairy cows during the lactation period in the southwest region, which consists of the following components: 400 parts of corn, 96 parts of wheat bran, 120 parts of high-fat corn, 60 parts of 43% soybean meal, and 42% cotton meal 140 parts, 100 parts of beet granule meal, 25 parts of sugarcane molasses, 17 parts of stone powder, 5.5 parts of calcium hydrogen phosphate, 8 parts of sodium chloride, 15 parts of sodium bicarbonate, 5 parts of magnesium oxide, 2.5 parts of yeast culture, vitamins, trace amounts 2 parts of elemental premix, 1 part of rumen-passed fat, 1 part of rumen-passed lysine, 0.05 parts of multidimensional electrolyte additive, 1 part of anti-fungal agent, and 1 part of mold-removing agent.

Embodiment 3

[0040] This embodiment is a concentrate supplement for dairy cows during the lactation period in the southwest region, which consists of the following components: 438 parts of corn, 50 parts of wheat bran, 100 parts of high-fat corn, 100 parts of 43% soybean meal, and 42% cotton meal 120 parts, 100 parts of beet granule meal, 25 parts of sugarcane molasses, 20 parts of stone powder, 5 parts of calcium hydrogen phosphate, 8 parts of sodium chloride, 18 parts of sodium bicarbonate, 6.5 parts of magnesium oxide, 2.5 parts of yeast culture, vitamins, trace amounts 2 parts of element premix, 2 parts of rumen-passed fat, 1 part of rumen-passed lysine, 0.05 parts of multidimensional electrolyte additive, 1 part of anti-mold agent, and 1 part of mold-removing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com