Fluorine-containing polymer/conductive fiber dielectric material and preparation method thereof

A technology of conductive fibers and dielectric materials, applied in fiber types, fiber processing, textiles and papermaking, etc., can solve problems that affect the practical application of polymer-based dielectric composite materials, accelerate dielectric thermal decomposition and aging, and reduce insulation performance , to achieve a wide range of use, increase the dielectric constant, and increase the effect of dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

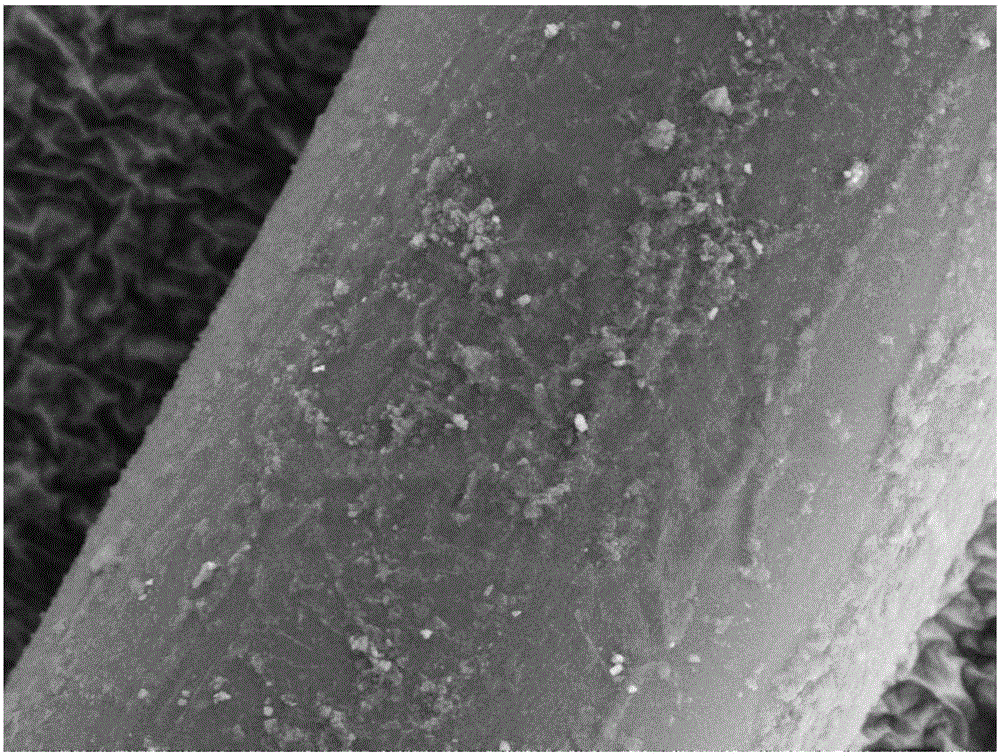

[0038]Take a 2m long PA66 fiber and soak it in ethanol solvent for 20-30min, then take it out and wash it with distilled water, then put it in a vacuum drying oven to dry for use. Weigh 1.215g of Tris, dissolve it in an appropriate amount of distilled water, stir with a glass rod until completely dissolved, then add 1.47ml of 2g / L HCl solution to adjust the pH to 8.5 to obtain a Tris-HCl solution with a pH of 8.5. 0.4 g of dopamine was weighed and added to the Tris-HCl solution configured above to obtain a 2 g / L dopamine solution. Then add PA66 fiber to soak for 3 minutes, then take it out and react in air for 2 minutes, pull it repeatedly 15 times, wash with deionized water and dry to obtain polydopamine-coated PA66 fiber, cut into pieces, length 0.1-5cm, and set aside.

[0039] Prepare a silver nitrate solution with a concentration of 20 g / L, and gradually add ammonia water until the precipitate completely disappears to obtain the corresponding silver ammonia solution. Imme...

Embodiment 2

[0043] Take a 2.5m long PA66 / PET composite fiber and soak it in ethanol solvent for 20-30min, then take it out and wash it with distilled water, then put it in a vacuum drying oven to dry for use. Weigh 1.224g of Tris and dissolve it in an appropriate amount of distilled water, stir it with a glass rod until it is completely dissolved, then add 1.51ml of 2g / L HCl solution to adjust the pH to 8. 0.4 g of dopamine was weighed and added to the Tris-HCl solution configured above to obtain a 1 g / L dopamine solution. Then add PA66 fiber to soak for 5 minutes, then take it out and react in the air for 3 minutes, repeat pulling 9 times, wash with deionized water and dry to obtain polydopamine-coated PA66 / PET composite fiber, cut into pieces, length 0.1-5cm, and set aside.

[0044] Prepare a silver nitrate solution with a concentration of 30 g / L, and gradually add ammonia water until the precipitate completely disappears to obtain the corresponding silver ammonia solution. Immerse the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com