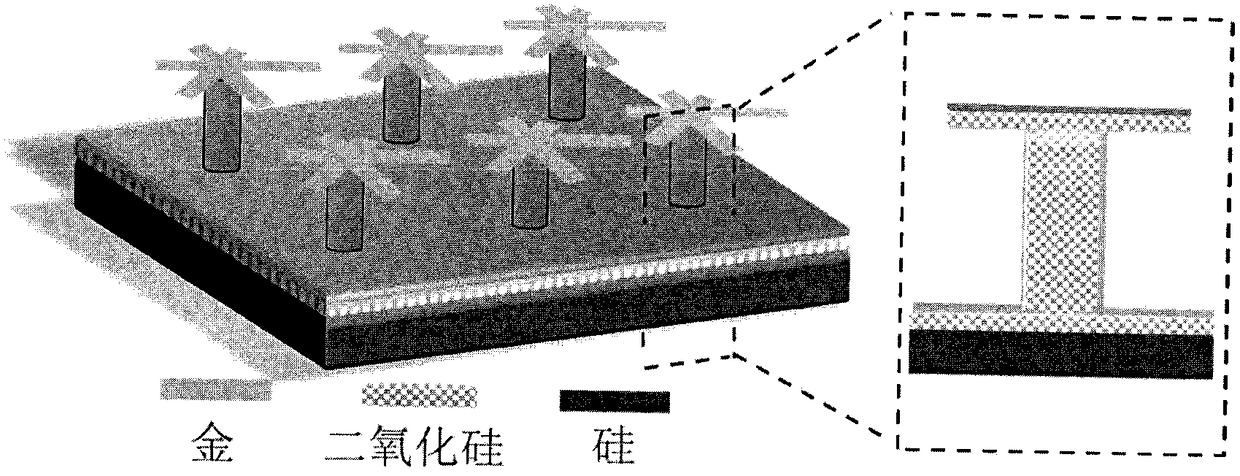

A Holographic Imaging Film Based on Surface Plasmon Coupling Structure

A surface plasmon and coupling structure technology, applied in nanotechnology, instruments, etc., can solve problems such as limited development, image distortion, and difficult adjustment of hologram color, and achieve the effect of improving reflection efficiency and wide viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) thermal oxidation passivation layer: utilize thermal oxidation growth on the surface of silicon (Si) substrate 1 Thick SiO 2 as a passivation layer.

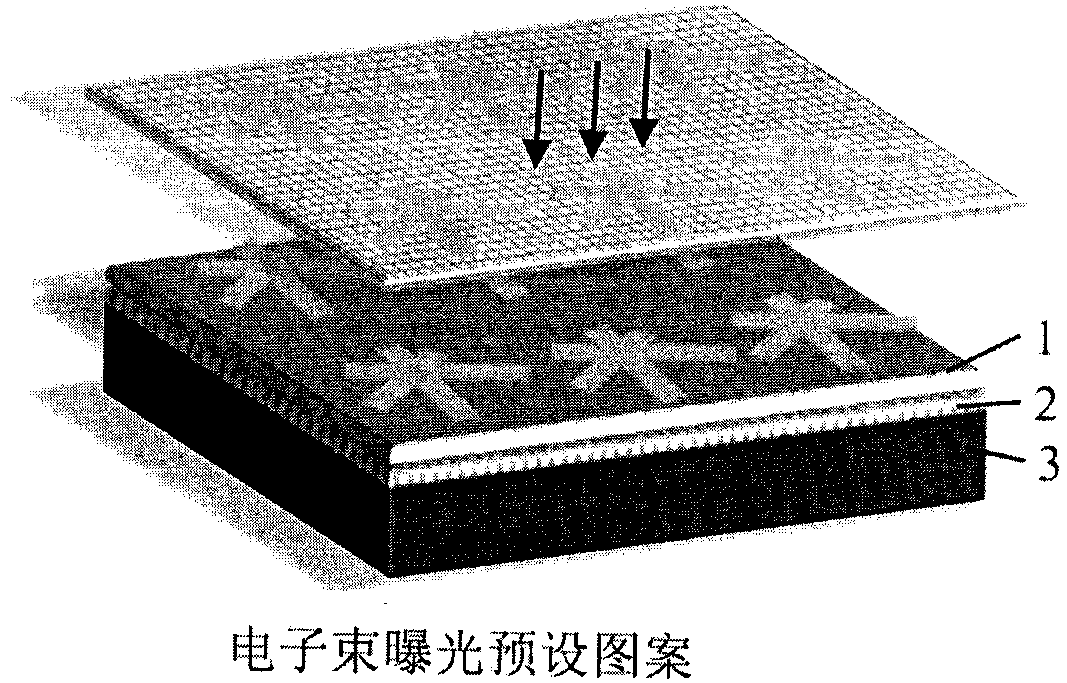

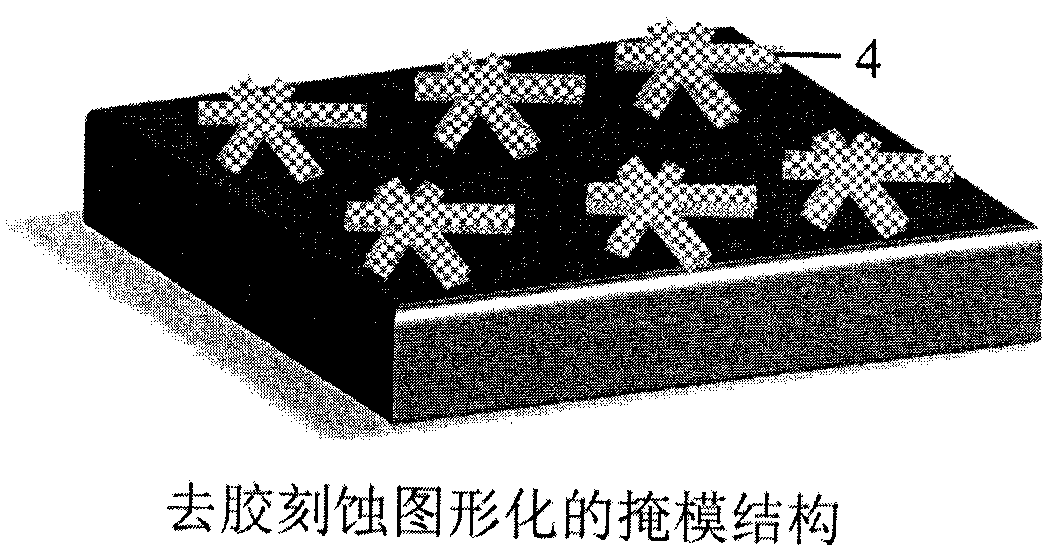

[0023] (2) Photolithographic patterning: Take AR-N7520.18 negative photoresist as an example, spin-coat it with a thickness of 100nm at a speed of 5000 rpm, and pre-bake it in an oven at 85°C for 5 minutes, using NanoBeam electronics The beam etching system exposes the photoresist with an accelerating voltage of 80kV, develops it in tetramethylammonium hydroxide (TMAH) developer solution for 1 minute, and rinses it with deionized water to obtain an imaged nanostructure array;

[0024] (3) Formation of insulating dielectric nanocolumns: use silicon oxide as a mask, etch the silicon substrate with a reactive ion etching machine, the power of the etching machine is 400W, SF 6 and C 4 f 8 The flow rates were 40 and 90 sccm / min, the etching time was 50 seconds, and SF 6 As an etching gas, C 4 f 6 As the polymer gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com