Coating agent and laminate

A coating agent and crosslinking agent technology, applied in the field of coating agents and laminates, can solve the problems of insufficient adhesion and chemical resistance, insufficient adhesion of cured coatings, etc. Achieves excellent chemical resistance and heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Next, the present invention will be specifically described by way of examples and comparative examples.

Synthetic example 1

[0100] (Synthesis Example 1: Synthesis of Aromatic Polyester Polyol (1))

[0101] While introducing nitrogen gas into a reaction container equipped with a thermometer, a nitrogen introduction pipe, and a stirrer, 27.6 parts by mass of isophthalic acid, 27.6 parts by mass of terephthalic acid, 19.9 parts by mass of diethylene glycol, and 0.03 parts by mass of dibutyltin oxide were added Parts, carry out polycondensation reaction at 230°C for 24 hours until the acid value is 1 or less at 180-230°C to obtain aromatic polyester polyol (1) [acid value 0.6, hydroxyl value 50.0, aromatic ring concentration 4.77mol / Kg ].

manufacture example 1

[0102] (Production example 1: Synthesis of vinyl ester resin (1))

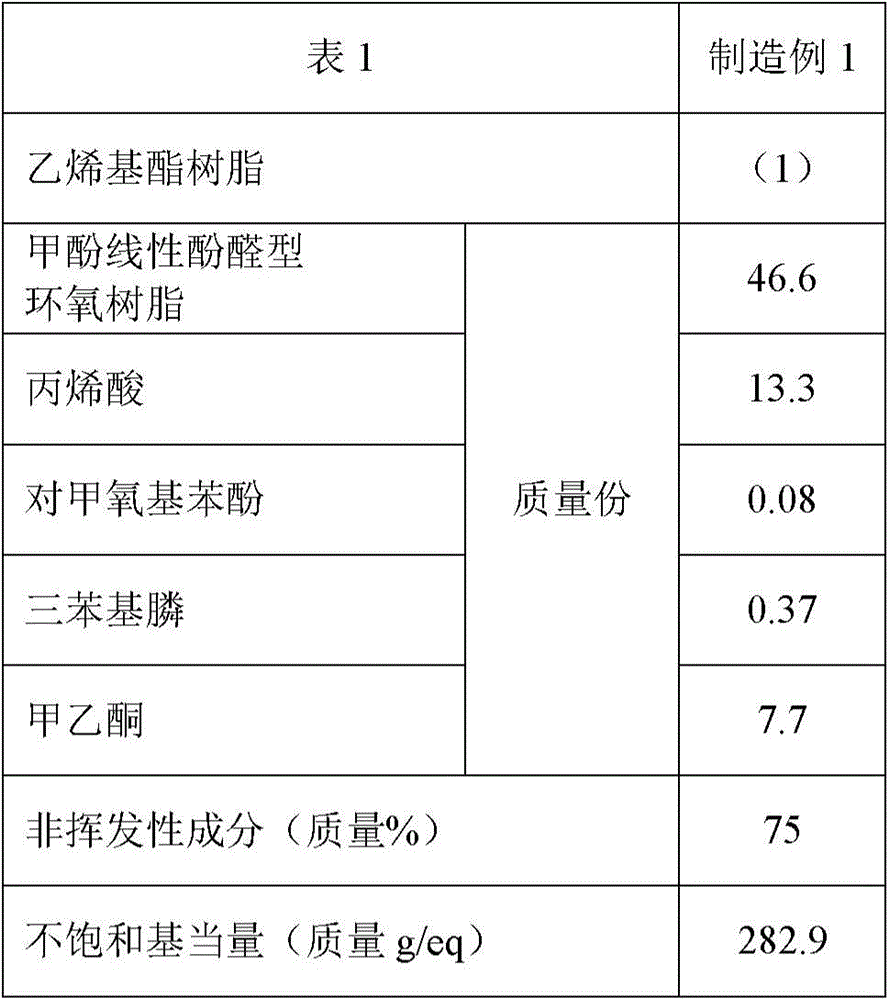

[0103] A cresol novolac type epoxy resin ("EPICLONN-673-80M" manufactured by DIC Corporation, solid content epoxy equivalent: 209 g / eq., non-volatile content: 80% by mass, solvent: methyl ethyl ketone) was charged into the reaction vessel. 46.7 parts by mass, 13.3 parts by mass of acrylic acid, 0.08 parts by mass of p-methoxyphenol, and 13.3 parts by mass of methyl ethyl ketone were stirred and mixed uniformly. Then, 0.37 parts by mass of triphenylphosphine was added, and the reaction was carried out at a reaction temperature of 80° C. until the acid value was 1.5 or less to obtain a solution having a nonvolatile content of vinyl ester resin (1) of 75% by mass.

[0104] Table 1 shows the raw materials of the vinyl ester resin (1) synthesized in Production Example 1.

[0105] [Table 1]

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com