Preparation method of aluminum hydroxide/zinc stannate microcapsule flame retardant and product of preparation method

A technology of aluminum hydroxide and zinc stannate, used in microcapsule preparations, microsphere preparation and other directions, can solve the problems of low plasticization efficiency, reduced material mechanical properties, low smoke elimination efficiency, etc. The effect of high synergistic flame retardant efficiency and simplified production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

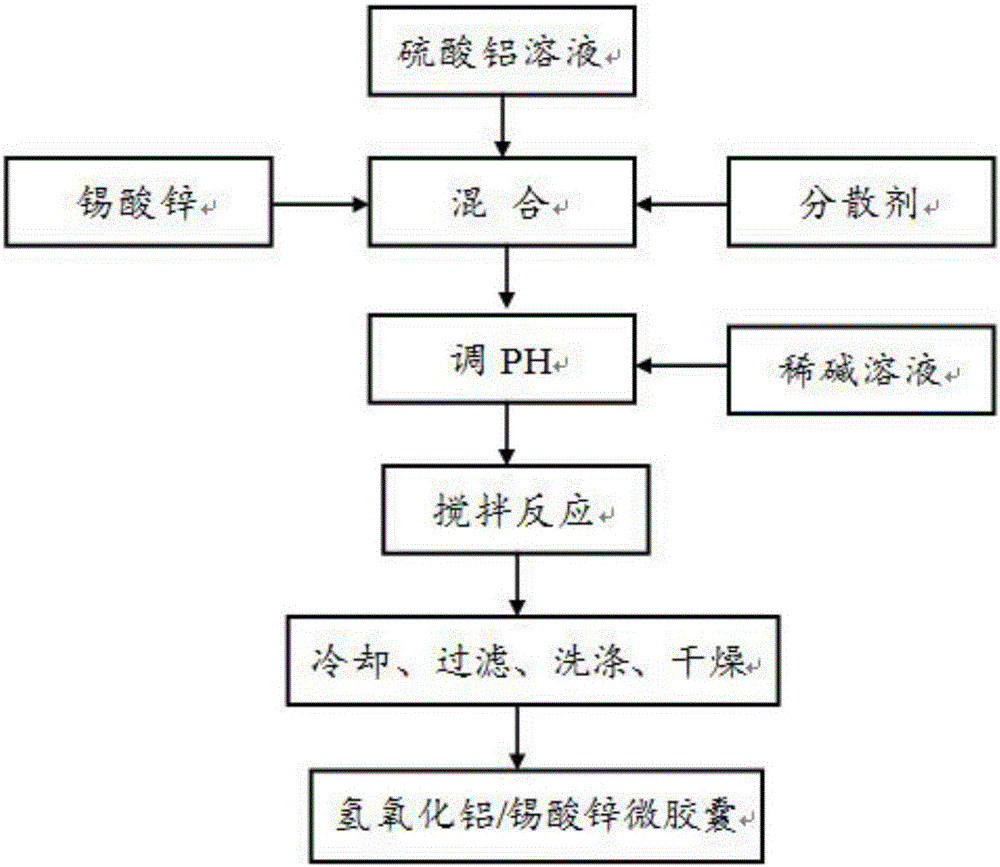

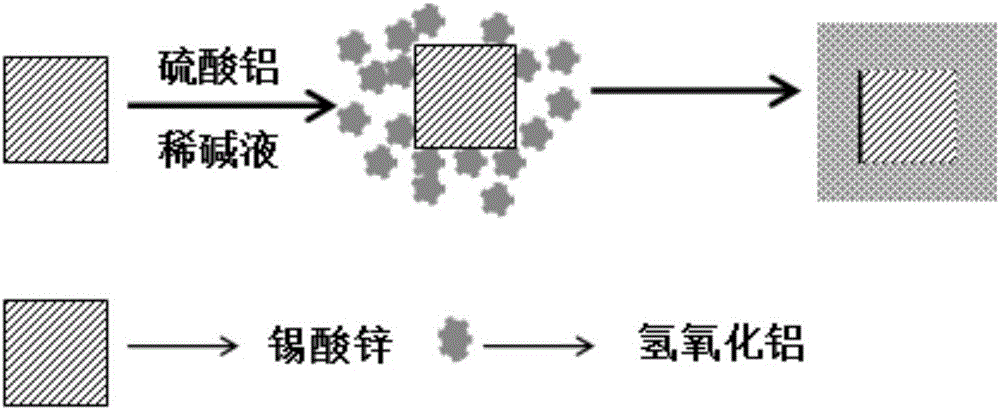

[0036] The preparation process is as figure 1 As shown, the mechanism is as figure 2 Shown, aluminum sulfate is mixed with mass fraction earlier and is 10% aluminum sulfate solution; Then zinc stannate (aluminum sulfate and zinc stannate mass ratio 1 / 4) and sodium hexametaphosphate dispersant (being the quality of zinc stannate 0.5%) was added to the aluminum sulfate solution to stir and disperse to obtain a mixed solution; then adjust the pH value of the mixed solution to 6.5, the stirring speed was 300r / min, the temperature was 55°C, and the reaction time was 3h; finally, cooling, filtering, washing, and drying were performed. Obtain aluminum hydroxide / zinc stannate microcapsule flame retardant.

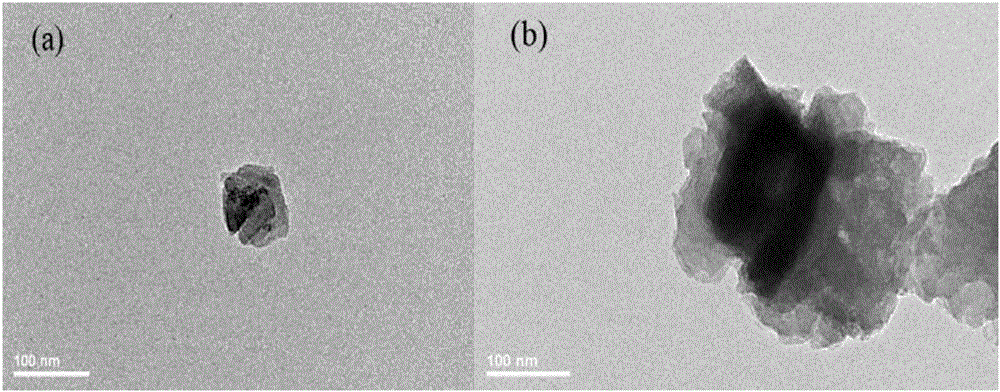

[0037] The obtained samples were characterized by TEM morphology, such as image 3 shown.

Embodiment 2

[0039] Aluminum sulfate is first prepared into a mass fraction of 10% aluminum sulfate solution; then zinc stannate (mass ratio of aluminum sulfate to zinc stannate 1 / 2) and sodium hexametaphosphate dispersant (0.5% of the mass of zinc stannate) Add it into the aluminum sulfate solution and stir to disperse to obtain a mixed solution; then adjust the pH value of the mixed solution to 6.5, the stirring speed is 300r / min, the temperature is 55°C, and the reaction time is 3h; finally, it is cooled, filtered, washed and dried to obtain Aluminum / zinc stannate microencapsulated flame retardant.

Embodiment 3

[0041] Aluminum sulfate is first prepared into a mass fraction of 10% aluminum sulfate solution; then zinc stannate (mass ratio of aluminum sulfate to zinc stannate 1 / 1) and sodium hexametaphosphate dispersant (0.5% of the mass of zinc stannate) Add it into the aluminum sulfate solution and stir to disperse to obtain a mixed solution; then adjust the pH value of the mixed solution to 6.5, the stirring speed is 300r / min, the temperature is 55°C, and the reaction time is 3h; finally, it is cooled, filtered, washed and dried to obtain Aluminum / zinc stannate microencapsulated flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com