Halogen-free flame-retardant thermoplastic elastomer material for electric wires and cables and preparation method of material

A thermoplastic elastomer, wire and cable technology, applied in the field of wire and cable materials, can solve the problems of poor weathering resistance, poor processing performance, poor aging resistance, etc., to improve high temperature resistance, physical and mechanical properties, and good processing performance. and anti-aging properties, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

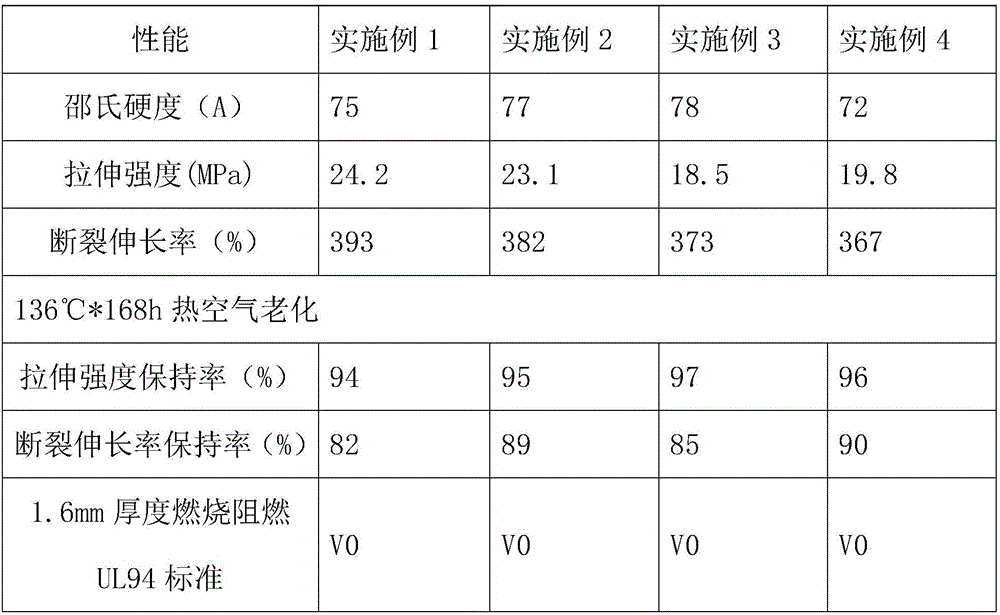

Examples

Embodiment 1

[0022] A halogen-free flame-retardant thermoplastic elastomer material for wire and cable, the raw materials of which include by weight: 20 parts of hydrogenated styrene block copolymer, 5 parts of polypropylene, 8 parts of POE thermoplastic elastomer, halogen-free flame retardant 40 parts, 15 parts of polyphenylene ether, 15 parts of compatibilizer, 2 parts of inorganic mineral, 15 parts of extender oil, 0.1 part of antioxidant, 0.3 part of lubricant, 0.1 part of crosslinking agent, 5 parts of styrene resin;

[0023] Wherein, the flame retardant is a mixture of 30% organic phosphate, 40% melamine polyphosphate and 30% polyphosphate by weight percentage;

[0024] The polystyrene block content in the hydrogenated styrene block copolymer is 40wt%, the molecular weight is 280,000, and the molecular structure is a linear structure; the melt index of the polypropylene is 3g / min; the polyphenylene ether The intrinsic viscosity is 0.5dl / g; the extender oil is paraffin oil with a kine...

Embodiment 2

[0026] A halogen-free flame-retardant thermoplastic elastomer material for wire and cable, the raw materials of which include by weight: 35 parts of styrene-ethylene-butylene-styrene polymer, 2 parts of homopolypropylene, and 15 parts of POE thermoplastic elastomer Parts, 25 parts of halogen-free flame retardant, 30 parts of poly(2,6-dimethyl-1,4-phenylene) ether, 5 parts of polypropylene-maleic anhydride graft, 10 parts of white smoke, filling 8 parts of oil, 0.5 part of antioxidant 168, 0.1 part of calcium stearate, 0.3 part of crosslinking agent, 2 parts of styrene resin;

[0027] Wherein, the flame retardant is a mixture of 50% organic phosphate, 20% melamine polyphosphate and 30% polyphosphate by weight percentage;

[0028] The preparation method of the organic phosphate comprises: adding graphite powder into acetic acid and stirring evenly, stirring and reacting at 140°C for 10 hours, drying, then adding triethylamine under the condition of nitrogen protection, stirring ...

Embodiment 3

[0032] A halogen-free flame-retardant thermoplastic elastomer material for wire and cable, the raw materials of which include by weight: 28 parts of styrene-ethylene-propylene-styrene polymer, 3 parts of copolymerized polypropylene, 11 parts of POE thermoplastic elastomer, 32 parts of halogen-free flame retardant, 23 parts of poly(2,6-dimethyl-1,4-phenylene) ether, 10 parts of compatibilizer, 6 parts of transparent powder, 11 parts of extender oil, 1010 parts of antioxidant 0.3 parts, 0.2 parts of silicone powder, 0.2 parts of crosslinking agent, 3 parts of styrene resin;

[0033] Wherein, the flame retardant is a mixture of 40% organic phosphate, 30% melamine polyphosphate and 30% polyphosphate by weight percentage; the preparation method of the organic phosphate comprises: graphite powder Add acetic acid and stir evenly, stir and react at 130°C for 11h, dry, then add triethylamine under the condition of nitrogen protection, stir evenly, heat at 300°C for 2h, cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com