A kind of graphene composite ternary positive electrode material and its preparation method and application

A technology of graphene composite and ternary materials, which is applied in the direction of electrical components, battery electrodes, structural parts, etc., and can solve the problems that it is difficult to give full play to the performance of graphene, and it is difficult to mix graphene and ternary materials uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

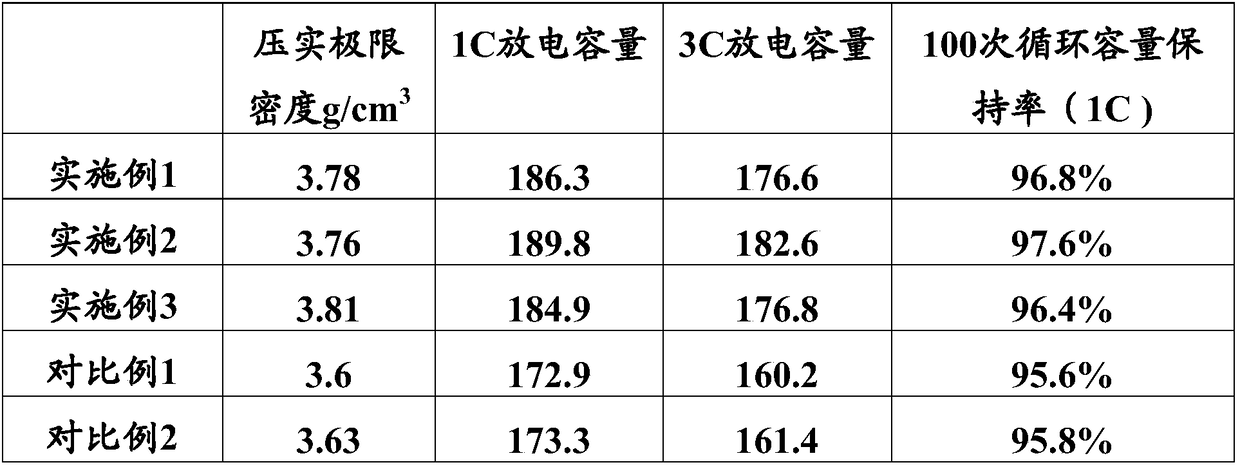

Examples

Embodiment 1

[0053] 1. Mix nickel sulfate, cobalt nitrate, and manganese nitrate in a molar ratio of 2:3:5, add 15wt% sodium hydroxide and 5wt% sodium peroxide accounting for the mass of the mixture, mix and grind evenly. Put the mixture into a muffle furnace for heat treatment at 500°C and keep it warm for 6 hours to obtain nickel cobalt manganate.

[0054] 2. Weigh graphite powder with a particle size of 5 μm and a purity of 99.9% with 2% of the total mass of nickel-cobalt oxomanganate, put it into 200 ml of 60% sulfuric acid solution, and stir to form a mixture. Slowly add the nickel cobalt manganese oxo-manganate in step 1 into the above mixture and stir, react at a low temperature of 10-30°C for 1 hour, at a medium temperature of 50-70°C for 5 hours, at a high temperature of 80-95°C for 3 hours, and obtain a mixture liquid.

[0055] 3. Disperse the mixed liquid reacted in step 2 into deionized water, and ultrasonicate for 60 minutes.

Embodiment 2

[0059] 1. Mix nickel sulfate, cobalt nitrate, and manganese nitrate in a molar ratio of 1:1:1, add 20wt% sodium hydroxide and 5wt% hydrogen peroxide accounting for the mass of the mixture, mix and grind evenly. Put the mixture into a muffle furnace for heat treatment at 700°C and keep it warm for 3 hours to obtain nickel cobalt manganate.

[0060] 2. Weigh graphite powder with a particle size of 5 μm and a purity of 99.9% with the total mass of nickel cobalt manganese oxymanganate as 4%, and put it in 400ml of 80% concentrated sulfuric acid and concentrated nitric acid mixed solution, and stir to form a mixture. Slowly add the nickel cobalt manganese oxo-manganate in step 1 into the above mixture and stir, react at a low temperature of 10-30°C for 2 hours, at a medium temperature of 50-70°C for 4 hours, at a high temperature of 80-95°C for 5 hours, and obtain a mixture liquid.

[0061] 3. Disperse the mixed liquid reacted in step 2 into deionized water, and sonicate for 80 mi...

Embodiment 3

[0065] 1. Mix nickel sulfate, cobalt nitrate, and manganese nitrate in a molar ratio of 3:3:4, add 10wt% sodium hydroxide and 5wt% potassium peroxide accounting for the mass of the mixture, mix and grind evenly. Put the mixture into a muffle furnace for heat treatment at 600°C and keep it warm for 4 hours to obtain nickel cobalt manganate.

[0066] 2. Weigh graphite powder with a particle size of 5 μm and a purity of 99.9% and put it into 500 ml of 70% concentrated sulfuric acid and concentrated nitric acid mixed solution, and stir to form a mixture. Slowly add the nickel-cobalt manganese oxo-manganate in step 1 into the above mixture and stir, react at a low temperature of 10-30°C for 3 hours, at a medium temperature of 50-70°C for 4 hours, and at a high temperature of 80-95°C for 5 hours, to obtain Mix liquid.

[0067] 3. Disperse the mixed liquid reacted in step 2 into deionized water, and sonicate for 40 minutes.

[0068] 4. Under the condition of high-speed stirring, sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com