Preparation method of textile fiber/graphene/NaTaO3 composite environmental catalytic material

A technology of textile fiber and catalytic material, which is applied in the field of preparation of textile fiber/graphene/NaTaO3 composite environmental catalytic material, can solve the problems of high processing cost, large loss of tearing strength, change of porous structure, etc., and achieve accelerated photocatalytic degradation The effect of reaction, reduction of intermediate by-products, and ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

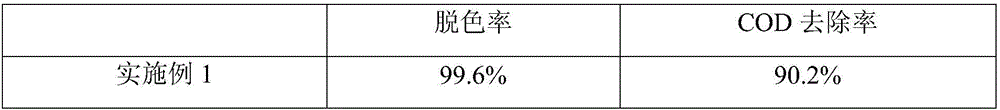

Examples

Embodiment 1

[0026] (1) Add 230mL of concentrated sulfuric acid and 3g of sodium nitrate into a beaker, cool in an ice-water bath, add 10g of graphite powder under stirring, after mixing evenly, grind 30g of potassium permanganate into fine powder and slowly add it, and stir and react for 1h at 0°C to obtain Graphite intercalation compound; after heating up to 35°C and continuing to react for 30 minutes, add 460mL of deionized water and continue to react for 30 minutes; then add 1400mL of deionized water and 30ml of 30% hydrogen peroxide in sequence, the solution changes from brick red to bright yellow, and continue to react After 10 minutes, filter, wash with 2% dilute hydrochloric acid, then wash with deionized water several times (8000rpm, 30min), vacuum dry at 50°C to obtain graphene oxide, redisperse graphene oxide in water, and ultrasonicate for 30min, drying the dispersion in a vacuum oven at 40°C to obtain graphene oxide;

[0027] (2) Select hemp fiber as a carrier, use acetone sol...

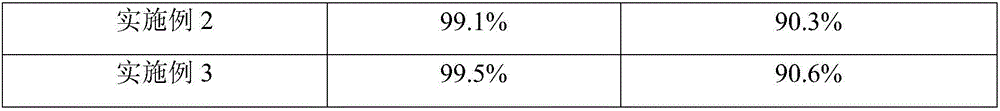

Embodiment 2

[0030] (1) Add 240mL of concentrated sulfuric acid and 4.5g of sodium nitrate into a beaker, cool in an ice-water bath, add 10g of graphite powder while stirring, after mixing evenly, grind 40g of potassium permanganate and add slowly, stir and react at 0°C for 1.5h , to obtain a graphite intercalation compound; after heating up to 40°C and continuing the reaction for 45 minutes, 530 mL of deionized water was added, and the reaction was continued for 37 minutes; then 1600 mL of deionized water and 45 ml of 30% hydrogen peroxide were added in sequence, and the solution changed from brick red to bright yellow, After continuing to react for 18 minutes, filter, wash with 3% dilute hydrochloric acid, then centrifuge (8000rpm, 37min) with deionized water several times, dry at 60°C in vacuum to obtain graphene oxide, redisperse graphene oxide in water, and ultrasonically For 340 minutes, dry the dispersion in a vacuum drying oven at 50°C to obtain graphene oxide;

[0031] (2) Select ...

Embodiment 3

[0034] (1) Add 250mL of concentrated sulfuric acid and 6g of sodium nitrate into a beaker, cool in an ice-water bath, add 10g of graphite powder while stirring, and after mixing evenly, grind 50g of potassium permanganate into fine powder and add slowly, then stir and react for 2 hours at 0°C to obtain Graphite intercalation compound; after heating up to 45°C and continuing to react for 60 minutes, add 600mL of deionized water and continue to react for 45 minutes; then add 1800mL of deionized water and 60ml of 30% hydrogen peroxide in sequence, the solution changes from brick red to bright yellow, and continue to react After 25 minutes, filter, wash with 4% dilute hydrochloric acid, then wash with deionized water several times (8000rpm, 45min), vacuum dry at 70°C to obtain graphene oxide, redisperse graphene oxide in water, and ultrasonicate for 50min. Dry the dispersion in a vacuum oven at 60°C to obtain graphene oxide;

[0035] (2) Select silk fiber as a carrier, use acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com