Preparation and application of graphene oxide-modified cellulose acetate forward osmosis membrane

A cellulose acetate and graphene modification technology, applied in the field of membrane separation, can solve the problems of little research on forward osmosis membranes, adverse effects on the structure and performance of hybrid membranes, low water flux, etc., and achieve stable membrane flux and Salt interception rate, enhanced anti-pollution ability, and high salt interception rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

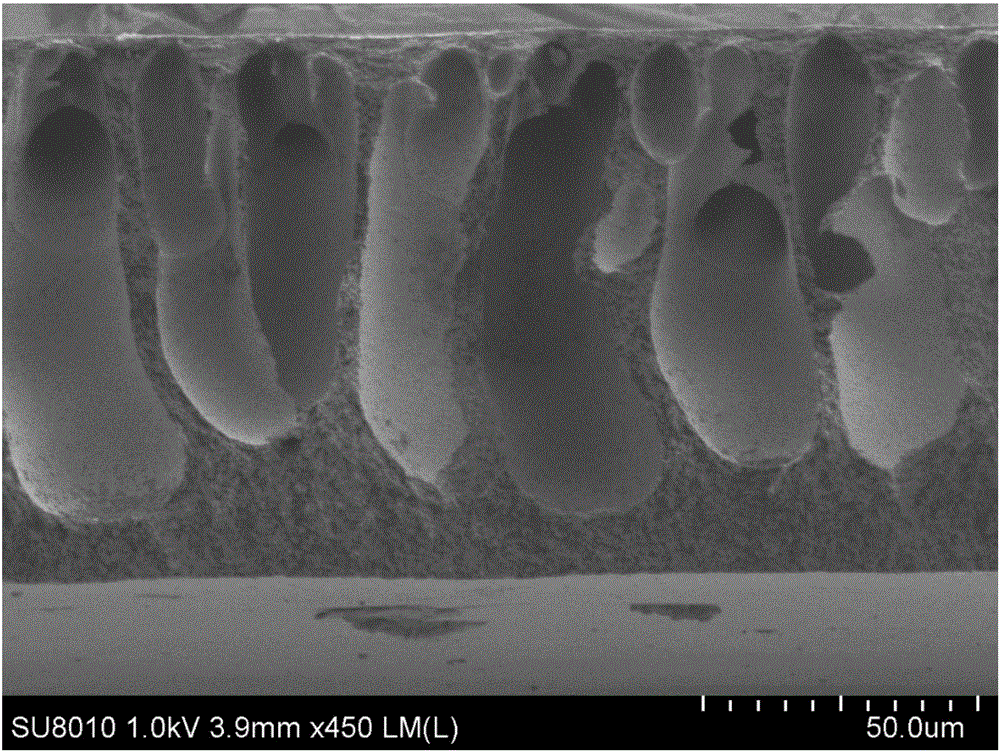

Image

Examples

Embodiment 1

[0036] Graphene oxide powder was purchased from Nanjing Xianfeng Nano Material Technology Co., Ltd., with a sheet diameter of 0.5-5 μm, a thickness of 0.8-1.2 nm, and a single layer.

[0037] 0.005 parts by mass of graphene oxide powder was added to 6.6 parts by mass of lactic acid (analytical pure), sealed and vibrated at room temperature for 2 hours, and then ultrasonicated in an ultrasonic field with a frequency of 60 kHz and a temperature of 25°C for 2 hours , the graphene oxide is fully and uniformly dispersed, then add 72.395 parts by mass of N-methyl-2-pyrrolidone (NMP) and a polymer mixed solvent of 5 parts by mass of acetone, and add 16 parts by mass of diacetone after sealing and shaking for 0.5 hours. Cellulose acetate (CA), then sealed and shaken at a temperature of 25°C for 20 hours until the cellulose acetate was fully dissolved, was prepared as a graphene oxide modified cellulose acetate forward osmosis membrane casting solution (100 parts by mass).

[0038] Put...

Embodiment 2

[0043]The proportion of cellulose acetate was adjusted to 13%, the proportions of N-methyl-2-pyrrolidone (NMP) and acetone were adjusted to 73.395 parts by mass and 7 parts by mass respectively, and the rest of the operations were the same as in Example 1.

[0044] The performance of the graphene oxide modified cellulose acetate forward osmosis membrane prepared in this example is as follows: using 1mol / L NaCl solution as the driving solution and deionized water as the raw material solution, in the test time of 1h, the prepared membrane Pure water flux is 21.8L / (m 2 h), the reverse salt flux is less than 4.8g / (m 2 h).

Embodiment 3

[0046] The proportions of graphene oxide and acetone were adjusted to 0.03 parts by mass and 4.975 parts by mass respectively, and the rest of the operations were the same as in Example 1.

[0047] The performance of the graphene oxide modified cellulose acetate forward osmosis membrane prepared in this example is as follows: using 1mol / L NaCl solution as the driving solution and deionized water as the raw material solution, in the test time of 1h, the prepared membrane Pure water flux is 30L / (m 2 h), the reverse salt flux is 6.5g / (m 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com