Macroscopic quantity preparation method of dispersed silver nanowires

A silver nanowire, monodisperse technology, applied in nanotechnology and other directions, can solve the problems of cumbersome post-processing, low cost, complicated process, etc., and achieve the effects of convenient industrial production, high uniformity, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for macro-preparing monodisperse silver nanowires, comprising the following steps:

[0032] 1) Under constant stirring, add 0.2g of polyvinylpyrrolidone (PVP) into the mixed solution of 40mg of ethylene glycol and glycerol to obtain a mixed reaction solution, heat up and stir the solution in an oil bath, and stir for one hour Finally, a transparent light yellow solution is formed, then weigh 0.1g of silver chloride and add to the above light yellow solution, slowly heat up to 80°C, use magnetic stirring to completely dissolve the silver chloride, and the color of the solution is orange-yellow;

[0033] 2) Add 1ml of sodium bromide solution with a concentration of 0.05g / ml to the orange-yellow solution obtained in step 1), and stir until a uniform solution is formed;

[0034] 3) Put the homogeneous solution obtained in step 2) in a reaction vessel, keep it warm for 5 hours in a 160°C incubator, add an equal volume of deionized water to the above homogeneous solu...

Embodiment 2

[0037] The surfactant used is polyvinylpyrrolidone (PVP), and the dosage is 8g; the silver salt used is silver nitrate, and the dosage is 4g; the concentration of the metal halide salt used is 0.05g / ml, and 4ml is added; the remaining parameters are the same as in Example 1 in the same.

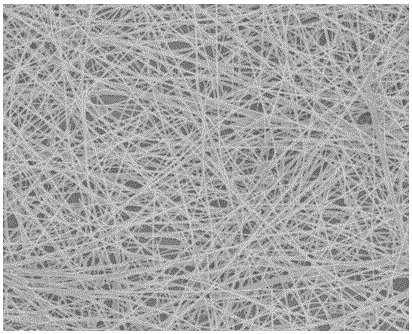

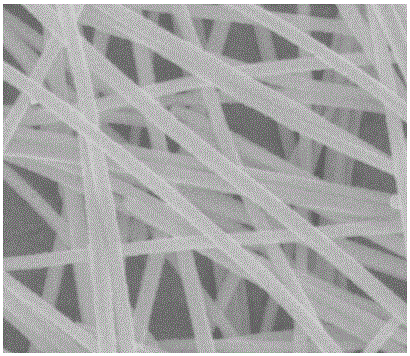

[0038] The silver nanowires synthesized by the method of this embodiment, the performance testing results are as follows: Figure 5 , Image 6 as shown, Figure 5 with Image 6 Represent the scanning low-magnification and high-magnification photos of the silver nanowires prepared under this condition respectively. From these two pictures, we can see that the silver nanowires prepared by this method still have a good crystallinity and homogeneity.

Embodiment 3

[0040] 1) In the case of constant stirring, add 0.2g polyacrylamide to 40mg ethylene glycol solution to obtain a reaction mixed solution. The solution is heated and stirred in an oil bath. After stirring for one hour, a transparent light yellow solution is formed. , then weighed 0.1g of silver chloride and added to the above light yellow solution, slowly warming up to 100°C, using magnetic stirring to completely dissolve the silver chloride, and the color of the solution was orange-yellow;

[0041] 2) Add 1ml of copper bromide solution to the orange-yellow solution obtained in step 1), the concentration is 0.05g / ml, stir evenly until a uniform solution is formed;

[0042] 3) Put the homogeneous solution obtained in step 2) into a reaction vessel, and keep it in a 160°C incubator for 5 hours;

[0043] 4) Add an equal volume of ethanol to the above-prepared silver nanowires, then centrifuge at 4000rpm for 10min, the result obtained is as follows Figure 7 As shown, when the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com