Environment-friendly crude oil decalcifying agent and preparation method thereof

A crude oil decalcifying agent, an environmentally friendly technology, which is used in the refining of hydrocarbon oil, petroleum industry and other directions, can solve the problems of easily blocking equipment pipelines by sediment, strong corrosion of industrial equipment, low calcium removal rate, etc., and achieves a green preparation process. Environmentally friendly, low production cost, and the effect of improving the decalcification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

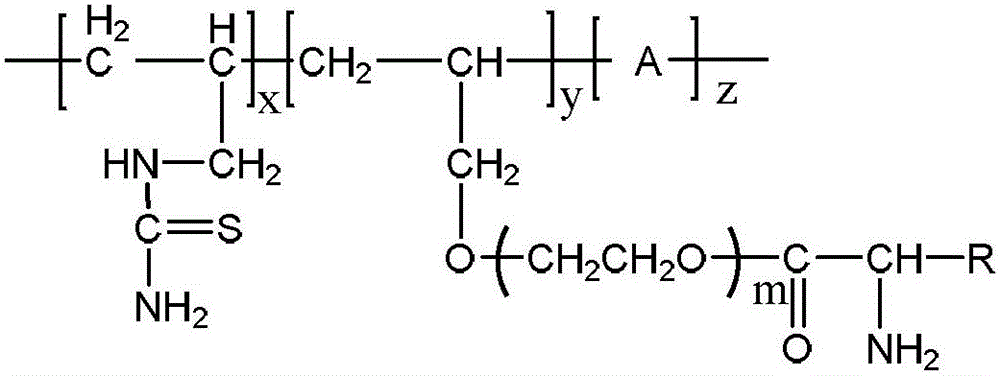

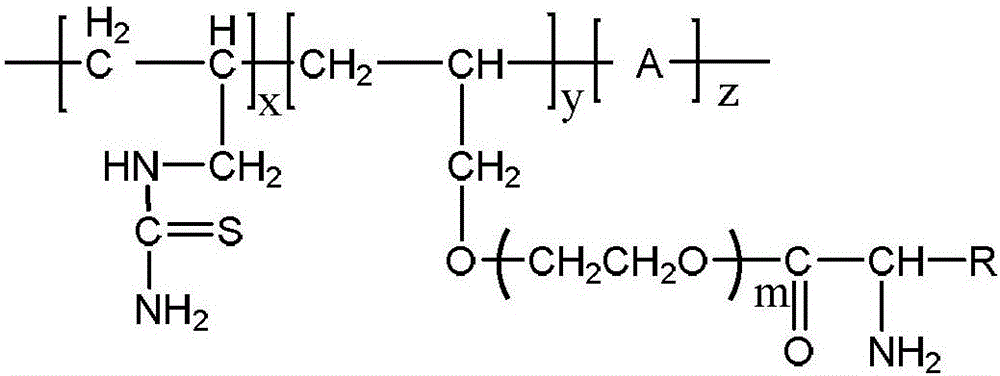

Image

Examples

Embodiment 1

[0019] Example 1: at N 2 Add 80g of allyloxypolyethylene glycol monoether and 20g of cysteine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 3 with 10wt% hydrochloric acid, react with microwave for 0.1h, and the microwave power is 300W. After the microwave reaction, continue the reaction at 90°C for 2 hours, then weigh 30g of allyl urea, 20g of monoethyl maleate, 10g of mercaptoethanol and 300g of distilled water into the reaction kettle and mix them evenly. After cooling down to 85°C, add 50g of 4wt% The sodium persulfate aqueous solution was dropped for 1 hour. After the dropwise addition, the reaction was continued at 85°C for 3 hours. After the temperature was lowered to 25°C, a brown-red transparent environment-friendly crude oil decalcifier was obtained.

[0020] Taking Luning Pipeline Oil as the experimental crude oil, the calcium content is 25.6ppm, and the iron content is 7.3ppm. When the dosage of the obtained environment-friendly crude oil ...

Embodiment 2

[0021] Example 2: at N 2 Add 100g of allyloxypolyethylene glycol monoether and 30g of asparagine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 2.5 with 10wt% hydrochloric acid, react with microwave for 0.3h, and the microwave power is 500W. After the reaction, continue to react at 60°C for 3 hours, then weigh 50g of allyl urea, 30g of monoethyl maleate, 10g of mercaptopropionic acid and 250g of distilled water into the reaction kettle and mix them evenly. After the temperature is raised to 85°C, add 50g of 6wt% Ammonium persulfate aqueous solution, after 2 hours of dripping, continue to react at 85°C for 4h, after dropping to 25°C, a brown-red transparent environment-friendly crude oil decalcifier is obtained.

[0022] Taking Luning Pipeline Oil as the experimental crude oil, its calcium content is 27.7ppm, and its iron content is 6.9ppm. When the dosage of the obtained environment-friendly crude oil decalcifier is 125ppm, the decalcification rate is 9...

Embodiment 3

[0023] Example 3: In N 2 Add 120g of allyloxypolyethylene glycol monoether and 35g of cysteine into the reaction kettle and mix them evenly at 25°C, adjust the pH to 3.5 with 15wt% hydrochloric acid, react with microwave for 0.5h, and the microwave power is 700W. After the microwave reaction, continue to react at 80°C for 5 hours, then weigh 45g of allyl urea, 30g of monomethyl fumarate, 15g of mercaptopropionic acid and 300g of distilled water into the reaction kettle and mix them evenly. After heating up to 85°C, add 50g of 8wt % sodium persulfonate aqueous solution, drop it in 0.5h, and continue to react at 85°C for 6h after the dropwise addition, and after dropping to 25°C, a brown-red transparent environment-friendly crude oil decalcifier is obtained.

[0024] Taking Luning Pipeline Oil as the experimental crude oil, its calcium content is 29.7ppm, and its iron content is 7.7ppm. When the dosage of the obtained environment-friendly crude oil decalcifier is 121ppm, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com