Method and device for removing high concentration hydrogen sulfide gas

A hydrogen sulfide, high-concentration technology, applied to the removal of high-concentration hydrogen sulfide gas, the removal method and device of high-concentration hydrogen sulfide gas, and the recovery process of high-concentration hydrogen sulfide gas, which can solve the problem of easy blockage of activated carbon pores and high equipment investment , unstable operation and other problems, to achieve the effect of increasing the processing capacity, high desulfurization efficiency and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The recovery of acid gas containing high-concentration hydrogen sulfide at the top of the sewage stripping tower is carried out according to the method and device of the present invention.

[0060] Method flow:

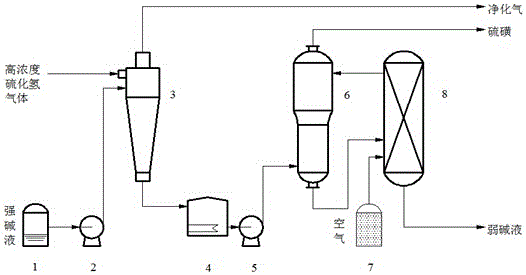

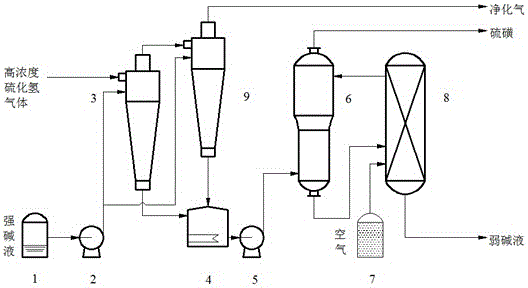

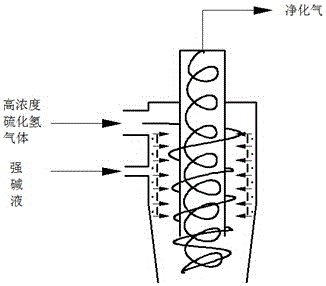

[0061] The specific method flow is as figure 2 As shown, the main operating conditions are shown in the table below:

[0062] Table 1 Main operating conditions of multi-stage swirl jet adsorber

[0063]

[0064] Table 2 Main operating parameters of adsorption liquid regenerator

[0065]

[0066] Technical effect: Due to the use of multi-stage swirl jet adsorbers to recover hydrogen sulfide, the efficiency of each stage is above 99%, and the overall efficiency is above 95%, which greatly improves the hydrogen sulfide removal effect and processing capacity. The use of renewable metal ion catalysts greatly improves the recovery rate of sulfur element. Compared with other methods and devices, the method and device of the present invention simplifies the ...

Embodiment 2

[0068] The desulfurization system of a 1,000,000-ton / year high-sulfur acid-containing hydrocracking device of a certain chemical company is carried out according to the method and device of the present invention.

[0069] Method flow:

[0070] The specific method flow is as figure 2 As shown, the main operating conditions are shown in the table below:

[0071] Table 3 Main operating conditions of multi-stage swirl jet adsorber

[0072]

[0073] Table 4 The main operating parameters of the adsorption liquid regenerator

[0074]

[0075] Technical effect: Due to the use of multi-stage swirl jet adsorbers to recover hydrogen sulfide, the separation accuracy is 3 microns, the removal rate of droplets of 5 microns and above exceeds 95%, and the concentration of hydrogen sulfide is reduced to below 10ppm. The continuous operation of the device is not less than 5 years, and the design life is 20 years. Compared with other methods and devices, the method and device of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com