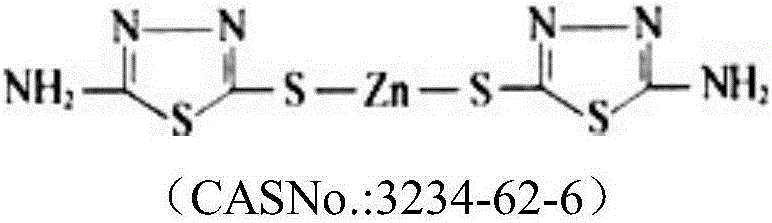

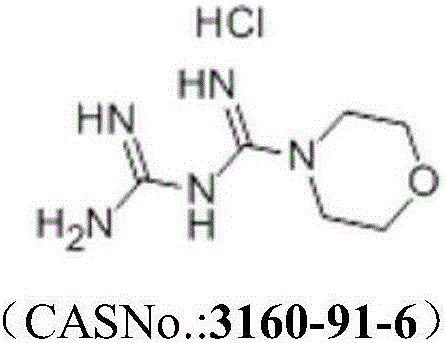

Sterilizing composition containing zinc thiazole and moroxydine hydrochloride and preparation and application of sterilizing composition

A technology of morpholine biguanide hydrochloride and composition, applied in the field of bactericidal active compound composition, can solve the problems that bactericidal active compounds cannot meet plant tolerance, bactericidal activity and prevent and treat viral diseases, and achieve good preventive or therapeutic effect, Effects of promoting plant growth and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

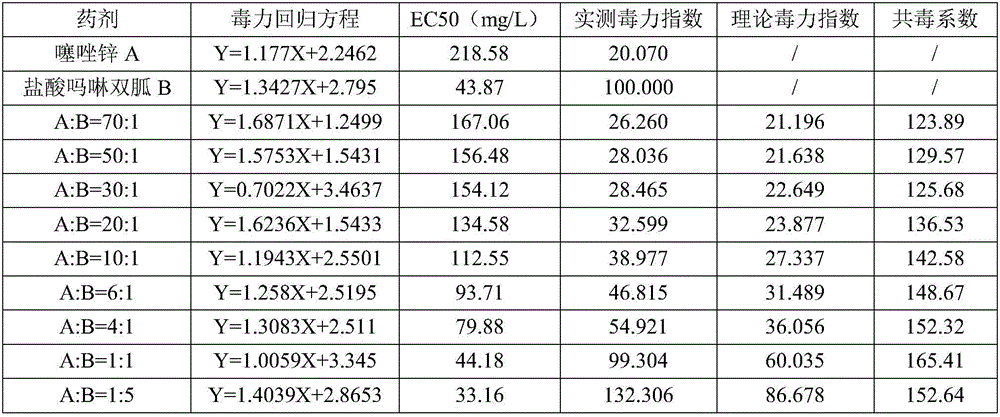

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: 40% (35%+5.0%) suspending agent

[0069] 40% active compound (35.0% thiazole zinc and 5.0% morpholine biguanide hydrochloride composition), fatty alcohol polyoxyethylene ether 2.0%, alkyl naphthalene sulfonate 2.0%, methyl naphthalene sulfonate sodium formaldehyde condensate 1.0% , gum arabic 0.05%, magnesium aluminum silicate 0.6%, glycerin 2.0%, sodium benzoate 0.4%, silicone defoamer 0.1%, deionized water to 100%, and put it into a high-shear homogeneous emulsifier High-speed shearing for 20 minutes, then transported to a sand mill, and circularly sanded for 1-3 times to obtain a suspending agent. The suspension contains 40% active compound.

Embodiment 2

[0070] Embodiment 2: 45% (40.0%+5.0%) suspending agent

[0071] 45% active compound (40.0% thiazole zinc and 5.0% morpholine biguanide hydrochloride composition), alkyl naphthalene sulfonate 2.0%, fatty alcohol polyoxyethylene ether sulfate 1.0%, sodium lignosulfonate 3.0%, octane Sodium starch alkenyl succinate 2.0%, glycerin 2.0%, potassium sorbate 0.2%, polyether defoamer 0.1%, distilled water to make up to 100%, put it into a high-shear homogeneous emulsifier for 25 minutes at high speed , and then pumped to a sand mill for 90 minutes of sanding, and filtered to obtain a suspending agent. The suspension contains 45% active compound.

Embodiment 3

[0072] Embodiment 3: 50% (10.0%+40.0%) suspending agent

[0073] 50% active compound (10.0% thiazole zinc and 40.0% morpholine biguanide hydrochloride composition), tallow ethoxyamine salt 1.0%, acyl glutamic acid salt 2.0%, dioctyl sulfosuccinic acid sodium salt 2.8% , Dioctyl sulfosuccinic acid sodium salt 1.0%, urea 3.0%, polyether defoamer 0.1%, deionized water added to 100%, put into a high-shear homogeneous emulsifier and shear at high speed for 20 minutes, After homogenizing with a high-pressure homogenizer, a 50% suspending agent is obtained. The suspension contains 50% active compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com